Technical Instructions LMV Series

Document No. LV3-1000

Appendix A Page 18 SCC Inc.

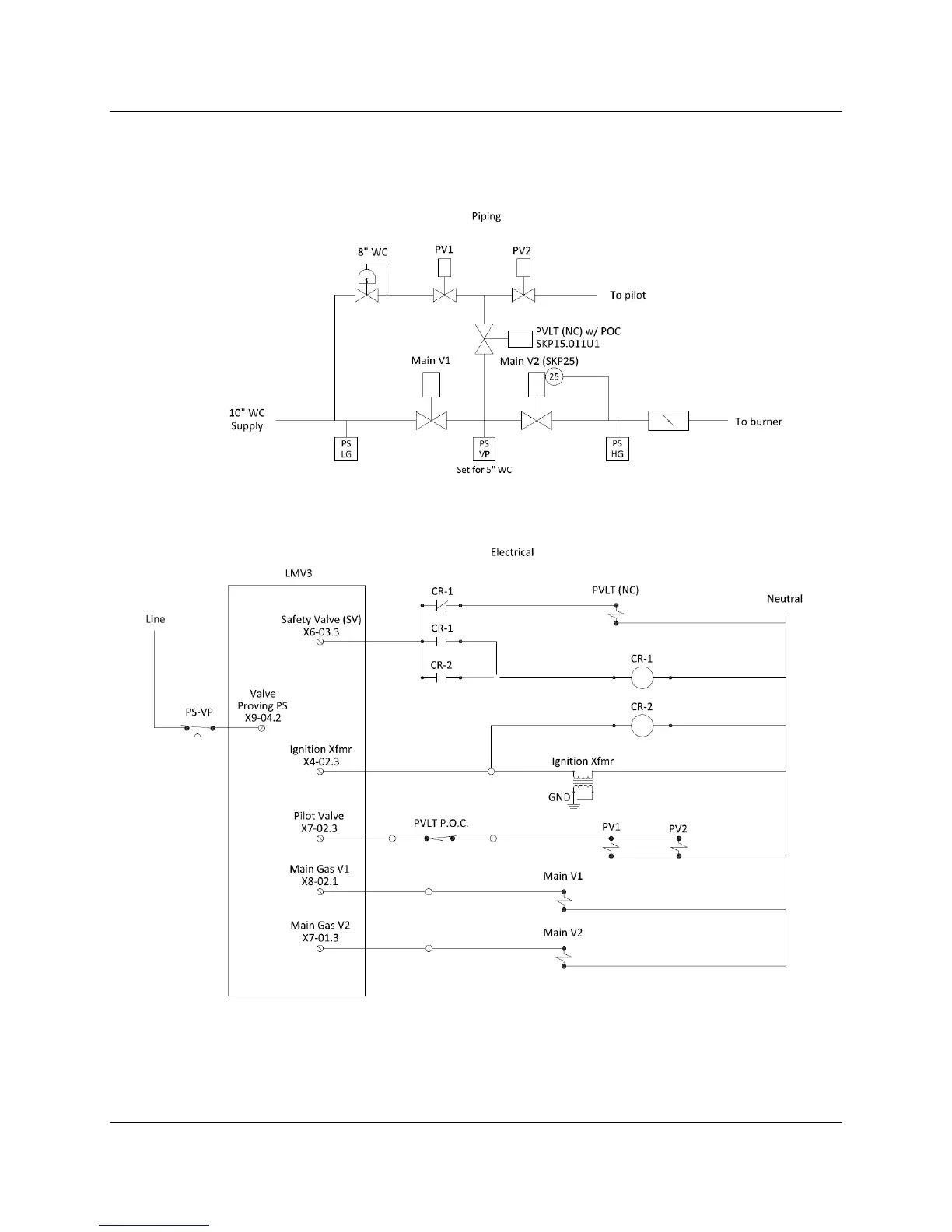

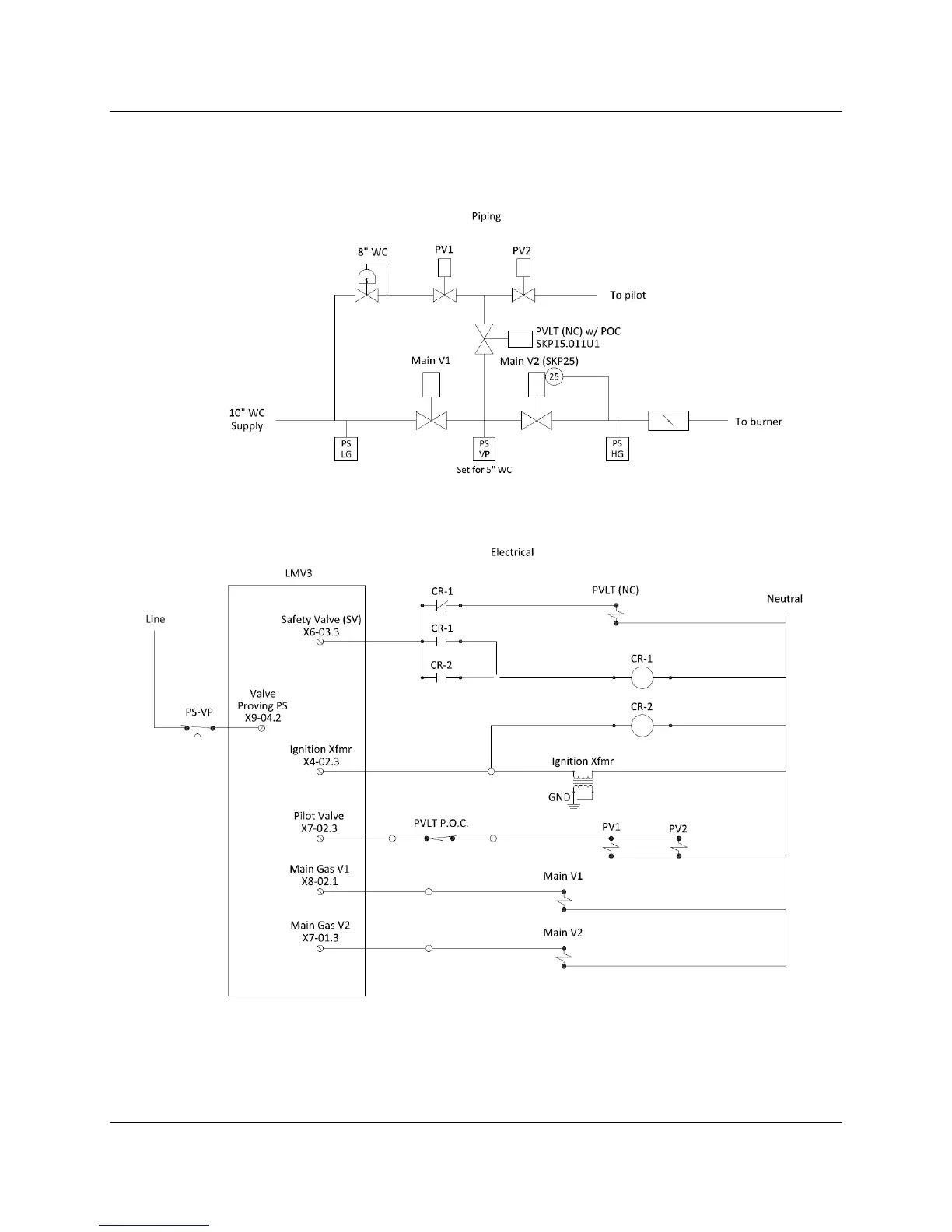

Pilot Valve Proving (continued)

Option 2: On Startup, SKP25 on the Main Gas Train, Solenoid Valves on the Pilot Train

Figure 9: Option 2 Piping and Electrical Schematics

Loading...

Loading...