105/213

Building Technologies Basic documentation LMV37.4... CC1P7546en

HVAC Products 11 Fan control 01.12.2009

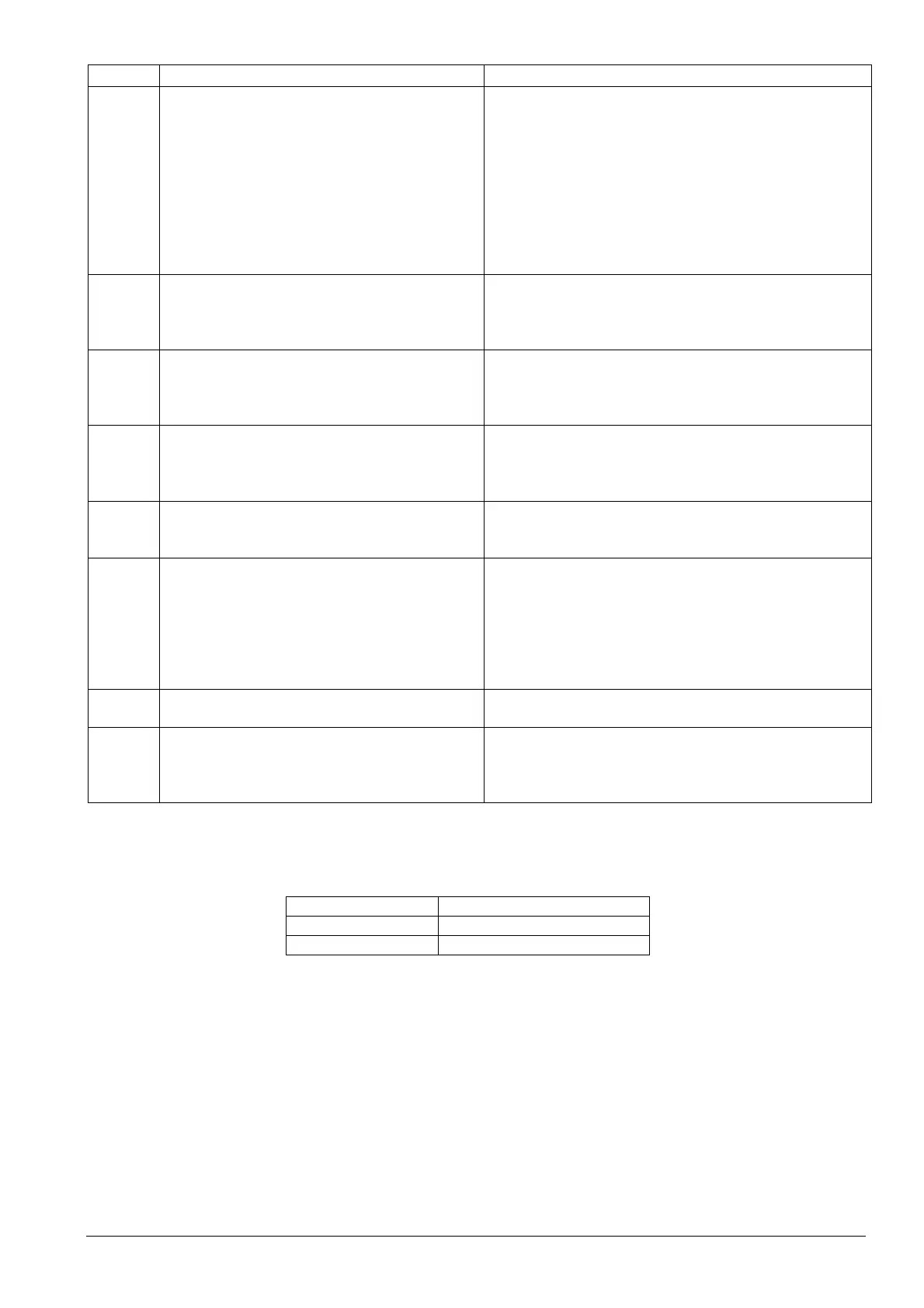

Value Error Recommended measures

-6 Unplausible sensor signals

The required pulse pattern (60°, 120°, 180°) has not

been correctly identified.

1. Speed sensor does not detect all tappets of the

sensor disk

→ check the distance.

2. As the motor turns, other metal parts are detected

also, in addition to the tappets

→ improve mount-

ing.

3. Electromagnetic interference on the sensor lines

→

check cable routing, improve EMC.

-7 Invalid standardized speed

Standardized speed measured does not lie in the

permissible range.

1. Motor turns too slowly or too fast.

-15 Speed deviation µC1 + µC2

The speeds of microcomputer 1 and 2 deviated too

much. This can be caused by wrong standardized

speeds (e.g. after restoring a data set to a new unit)

→ repeat standardization and check the fuel-air ratio

-20 Wrong phase of phase manager

Standardization was made in a wrong phase.

1. Permitted are only phases

≤12 → controller OFF,

start standardization again.

-21 Safety loop / burner flange open

Safety loop or burner flange is open.

1. Repeat standardization with safety loop closed.

-22 Air actuator not referenced

Air actuator is not referenced or has lost its reference

1. Check if the reference position can be approached.

2. Check if actuators have been mixed up.

3. If error only occurs after standardization was star-

ted, the actuator is possibly overloaded and cannot

reach the required position.

-23 VSD deactivated

Standardization was started with VSD deactivated →

activate VSD and repeat standardization

-24 No valid operating mode

Standardization was started with no valid operating

mode

→ select a valid operating mode and repeat standardi-

zation

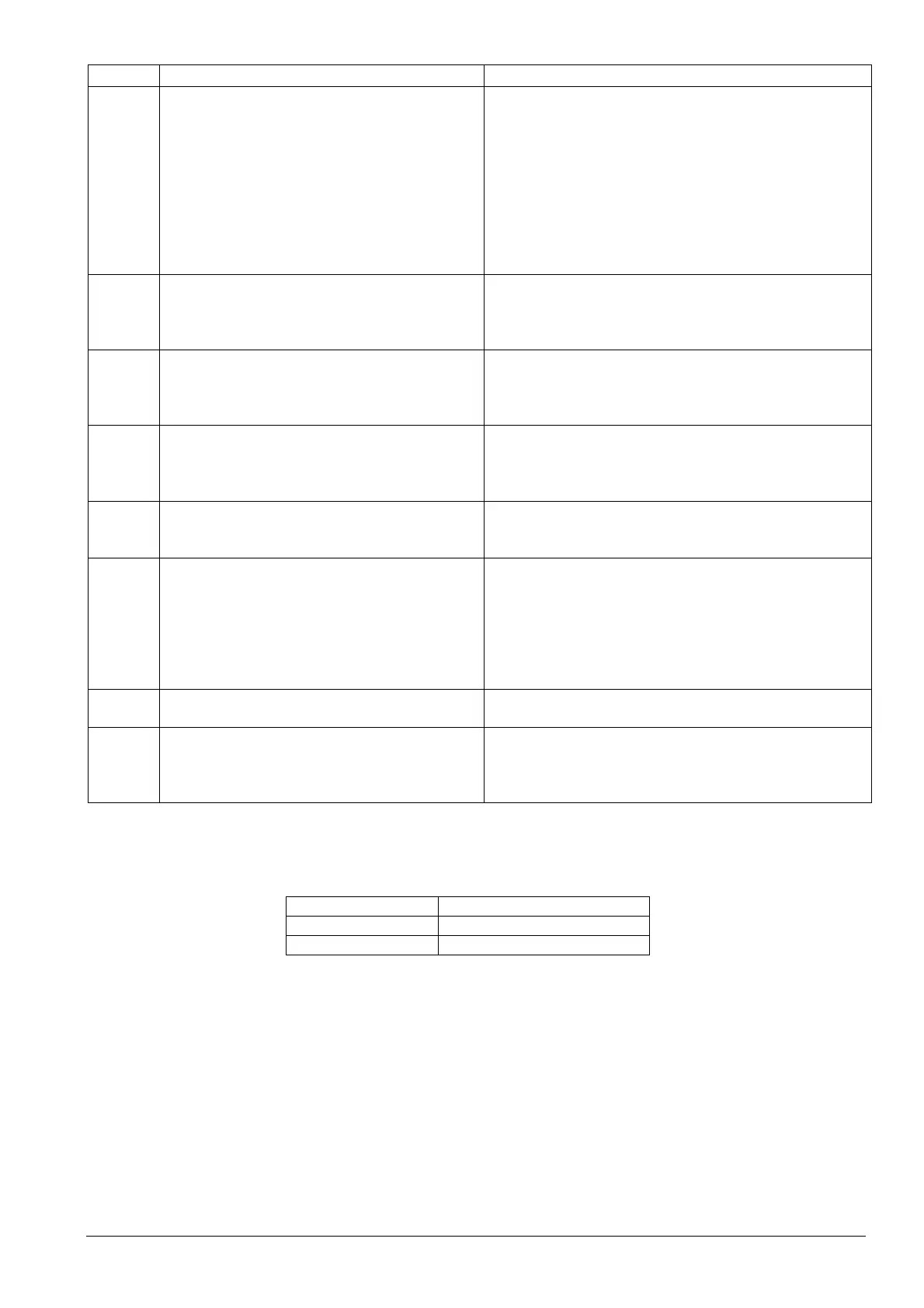

The result of speed standardization (100% speed) can be read out via parameter. The

speeds acquired by the 2 microcontrollers can differ by about 1.5%, the reason being

slightly different resonator frequencies.

Parameter

642.0 Standardized speed of μC1

642.1 Standardized speed of μC2

11.12 Control of fan motor with pneumatic air-

fuel ratio control

If the control of the fan motor is employed for burners with pneumatic air-fuel ratio con-

trol, only the control path is used. There is no need to connect a speed feedback signal

and to have speed control (for operating modes, refer to chapter

Selection of operating

mode

).

Loading...

Loading...