(1*,1((5,1*,1)250$7,21 ,QWHUQDWLRQDO(QJOLVK

MICROMASTER 420 Reference Manual

20 Issue A1

2.9

Braking

Reducing the output frequency of the inverter will cause the motor to slow down

and as the frequency is gradually reduced to zero the motor will stop. Reducing

the output frequency too rapidly may cause the motor to act as a generator and

cause a negative current (regeneration) to return to the DC link. To overcome this

possibility the MICROMASTER 420 employs a number of methods to control

braking. These options are described in the following paragraphs.

The method of bringing the motor to a standstill is selected by the user depending

on operational requirements.

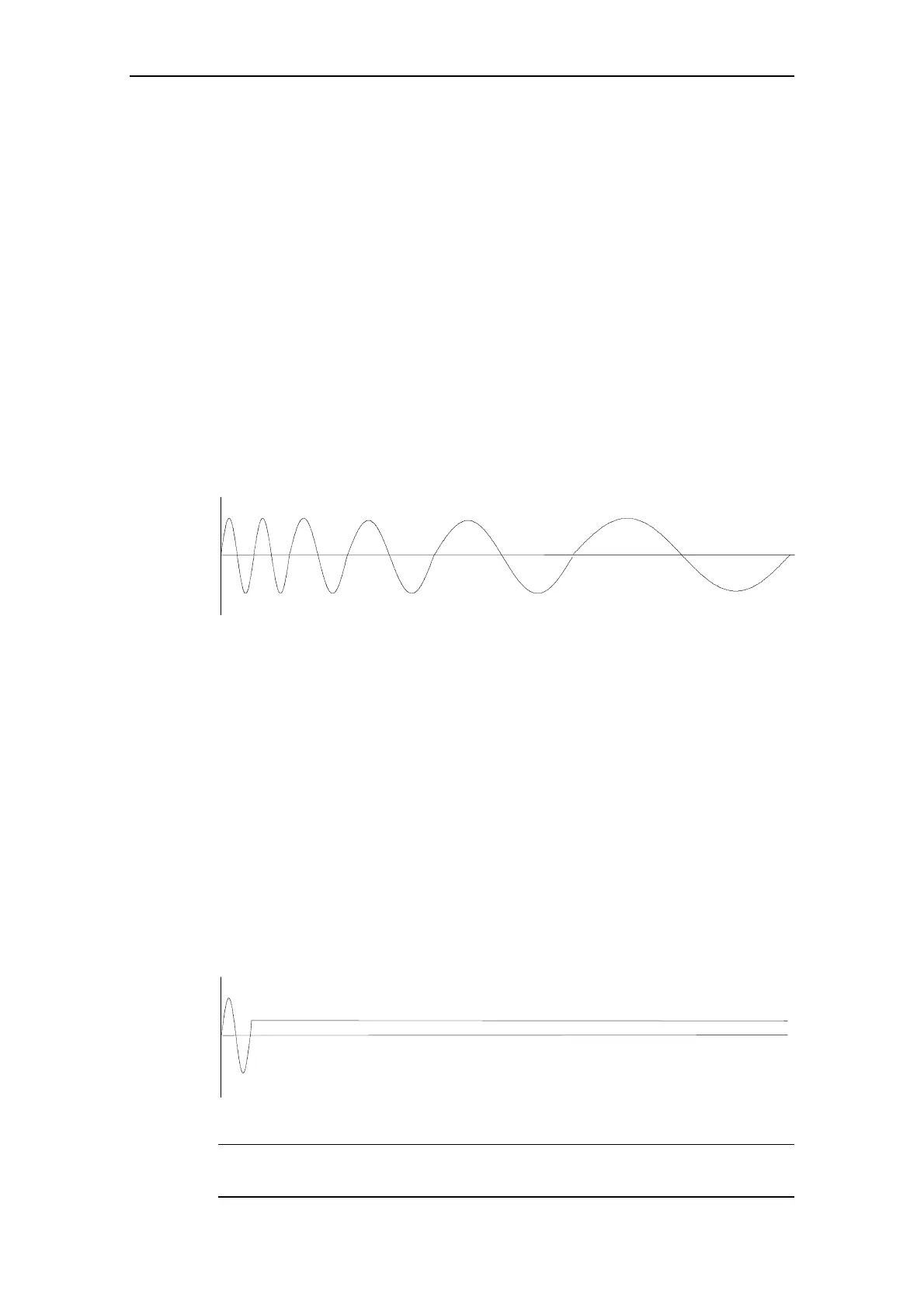

2.9.1 Normal Braking

The usual or normal braking method is to allow the motor to come to a standstill at

the selected ramp-down rate (OFF1), to coast to a standstill (OFF2) or to quickly

ramp down (OFF3) without applying any additional braking. (Refer to parameters

P0701, P0702 and P0703). However, if regeneration does cause tripping, DC or

Compound braking methods may be considered.

Figure 2-11 Frequency Ramp Down

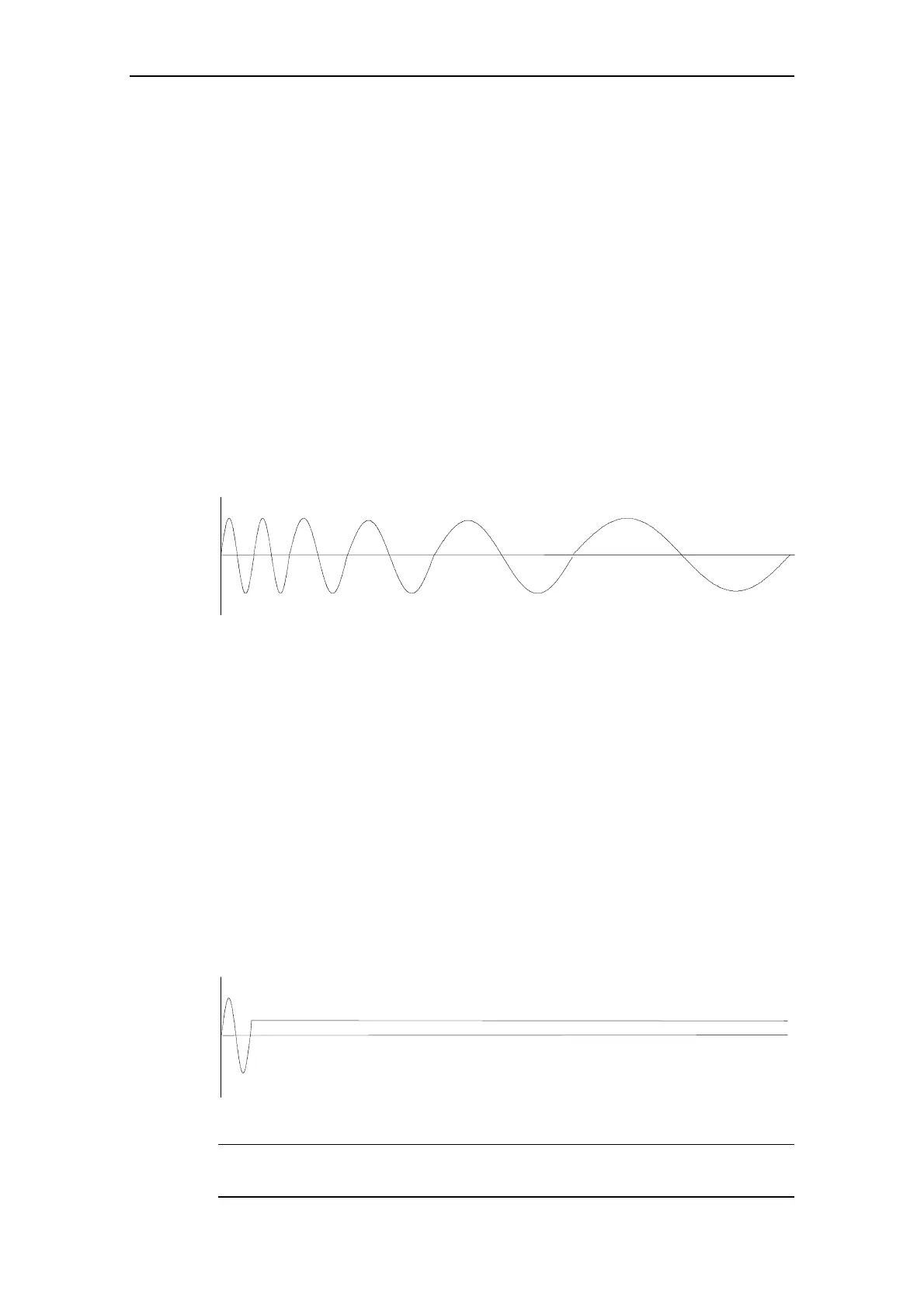

2.9.2 DC Braking

In this method a controlled DC voltage is applied to the rotor. When using DC

braking, the inverter output pulses are disabled and the actual time taken to bring

the motor to a standstill cannot be predicted. Stored energy in the motor and the

load is dissipated in the rotor therefore no regeneration occurs.

The DC braking current is defined as a percentage of nominal motor current using

parameter P1236. The current will be applied only when the motor is sufficiently

demagnetized. If the demagnetization time for the motor (P0347), is reduced too

much then the drive will trip on over current (F0001) when DC braking is activated.

DC braking can be enabled by an external source such as a digital input.

Figure 2-12 DC Braking

1RWH

Frequent use of DC braking can cause the motor to overheat.

Loading...

Loading...