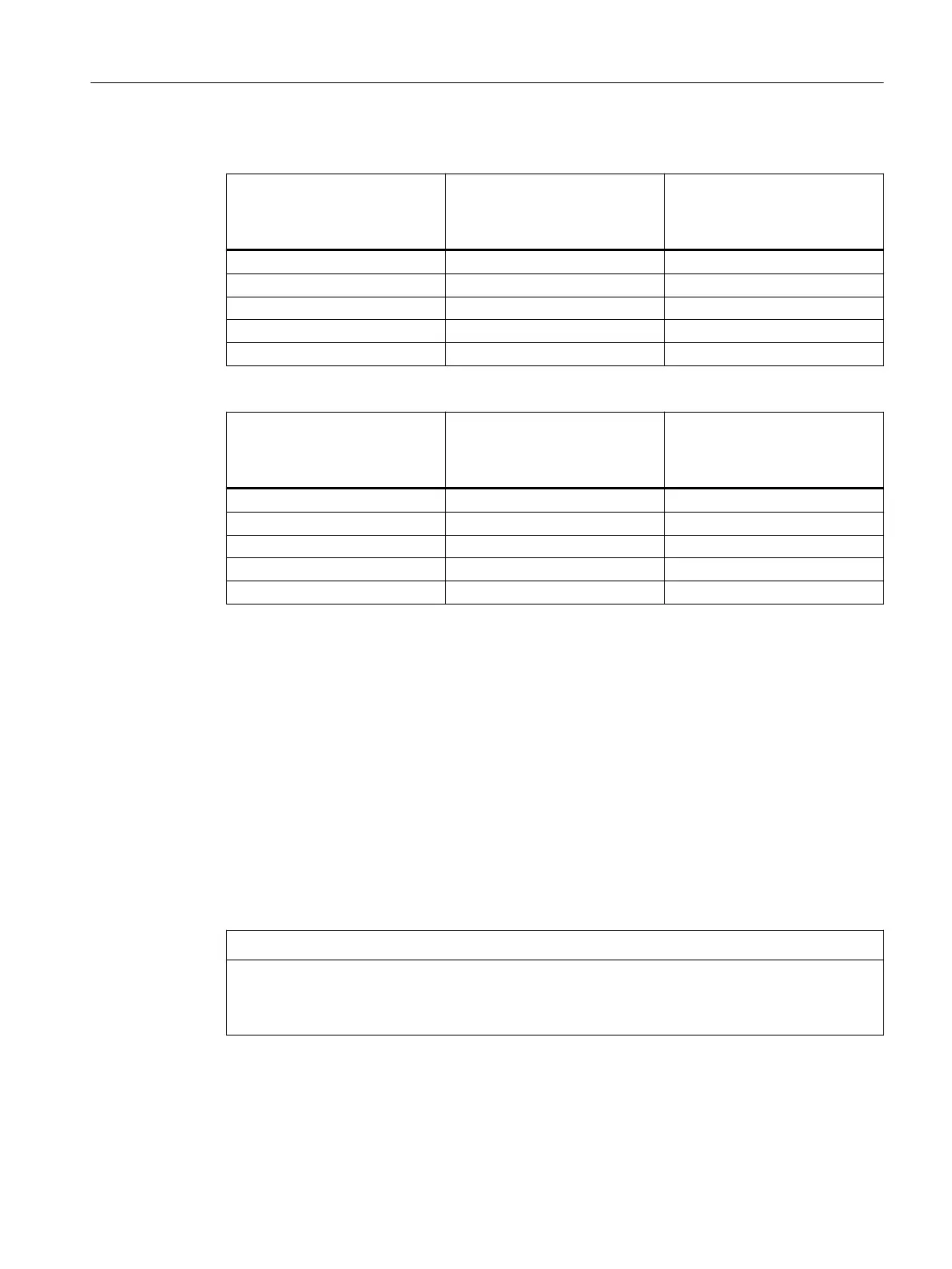

Apply the following torques when clamping the cables using the cap nut:

Torque cap nut with cable en‐

tries made from polyamide,

manufacturer: WISKA, type:

ESKE/1-eand ESKE/1-i [Nm]

Torque cap nut with cable en‐

tries made from brass, manu‐

facturer: WISKA, type: EMSKE-L

[Nm]

Cable entry M16 1.3 4.0

Cable entry M20 1.5 8.0

Cable entry M25 2.0 10.0

Cable entry M32 3.3 20.0

Cable entry M40 10.0 20.0

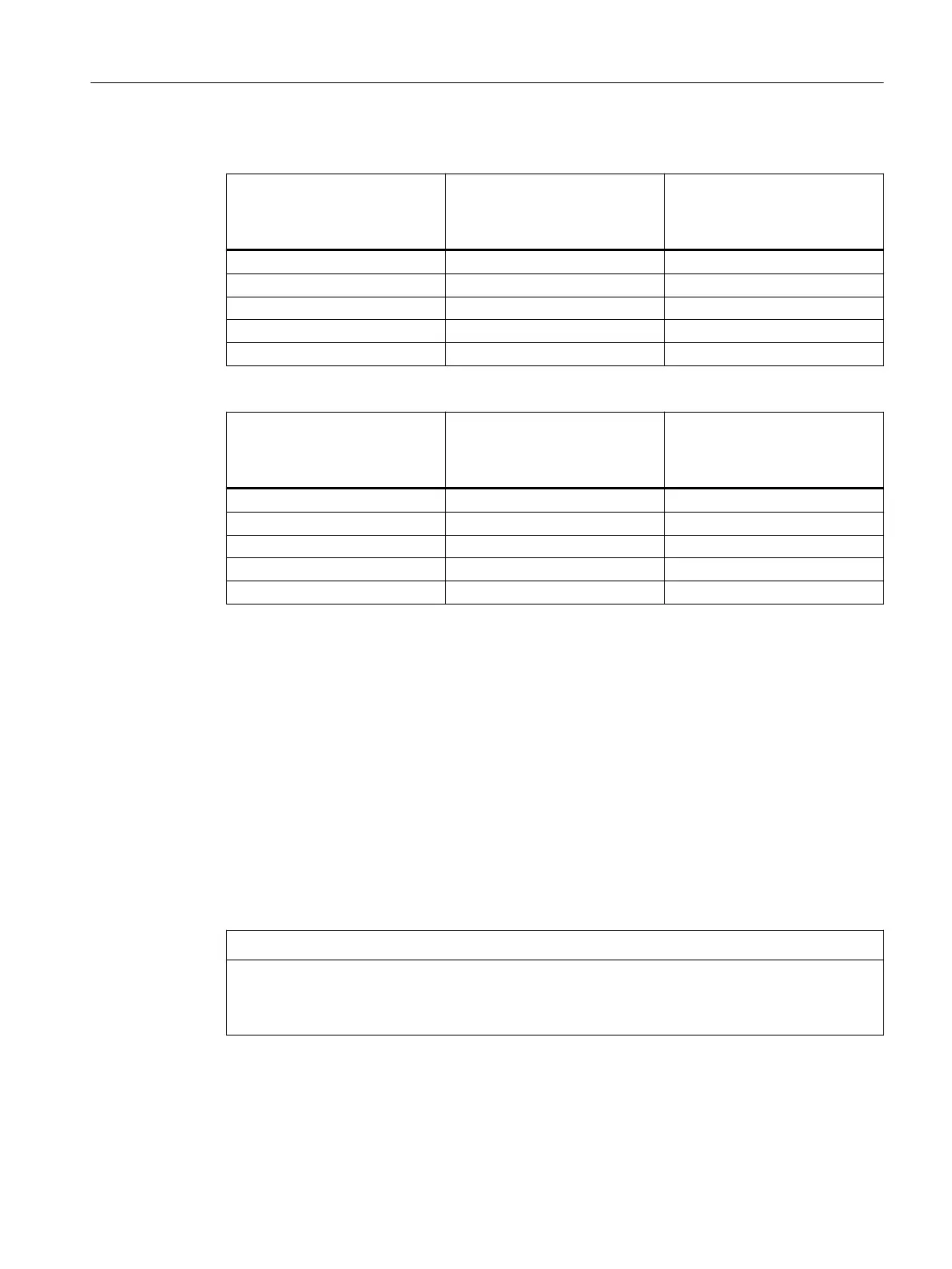

The following cable clamping ranges apply for the cable entries:

Clamping range for cable en‐

tries made from polyamide,

manufacturer: WISKA, type:

ESKE/1-eand ESKE/1-i [mm]

Clamping range for cable en‐

tries made from brass, manu‐

facturer: WISKA, type: EMSKE-L

[mm]

Cable entry M16 4.5-9 5-10

Cable entry M20 7-13 6-13

Cable entry M25 10-17 10-17

Cable entry M32 13-21 13-21

Cable entry M40 17-28 16-28

To use smaller cable diameters, use reducing inserts of type RDE from the manufacturer

WISKA.

Refer to the respective manufacturer's documentation for more information and technical

specications.

Before installation and commissioning, ensure that:

• the cable and conductor entries are not damaged,

• the cable and conductor entries are tightened in accordance with the recommended torques

and

• the cables and wires are properly inserted.

For cable and conductor entries that dier in type or manufacturer, refer to the information

and instructions provided in the respective manufacturer's documentation.

Relieve the tension on the cables outside the enclosure so that the cable gland is not stressed.

NOTICE

Closing the unused screw glands

Use the supplied red dummy plugs to close any cable glands not in use. Only then is it ensured

that the degree of protection is retained.

Description

4.6Details of the enclosure

Distributed I/O device 6DL2804-1xxxx & 6DL2804-2xxxx

Hardware Installation Manual, 11/2023, A5E42025214-AC 17

Loading...

Loading...