5.2 Conguring procedure

Motion Control

Drives are optimized for motion control applications. They execute linear or rotary movements

within a dened movement cycle. All movements should be optimized in terms of time.

As a result, drives must meet the following requirements:

• High dynamic response, i.e. short rise times

• Capable of overload, i.e. a high reserve for accelerating

• Wide control range, i.e. high resolution for precise positioning.

The following table "Conguring procedure" is valid for synchronous and induction motors.

General conguring procedure

The function description of the machine provides the basis for conguration. The components

are selected according to physical interdependencies and the selection process is usually carried

out in the following sequence of steps:

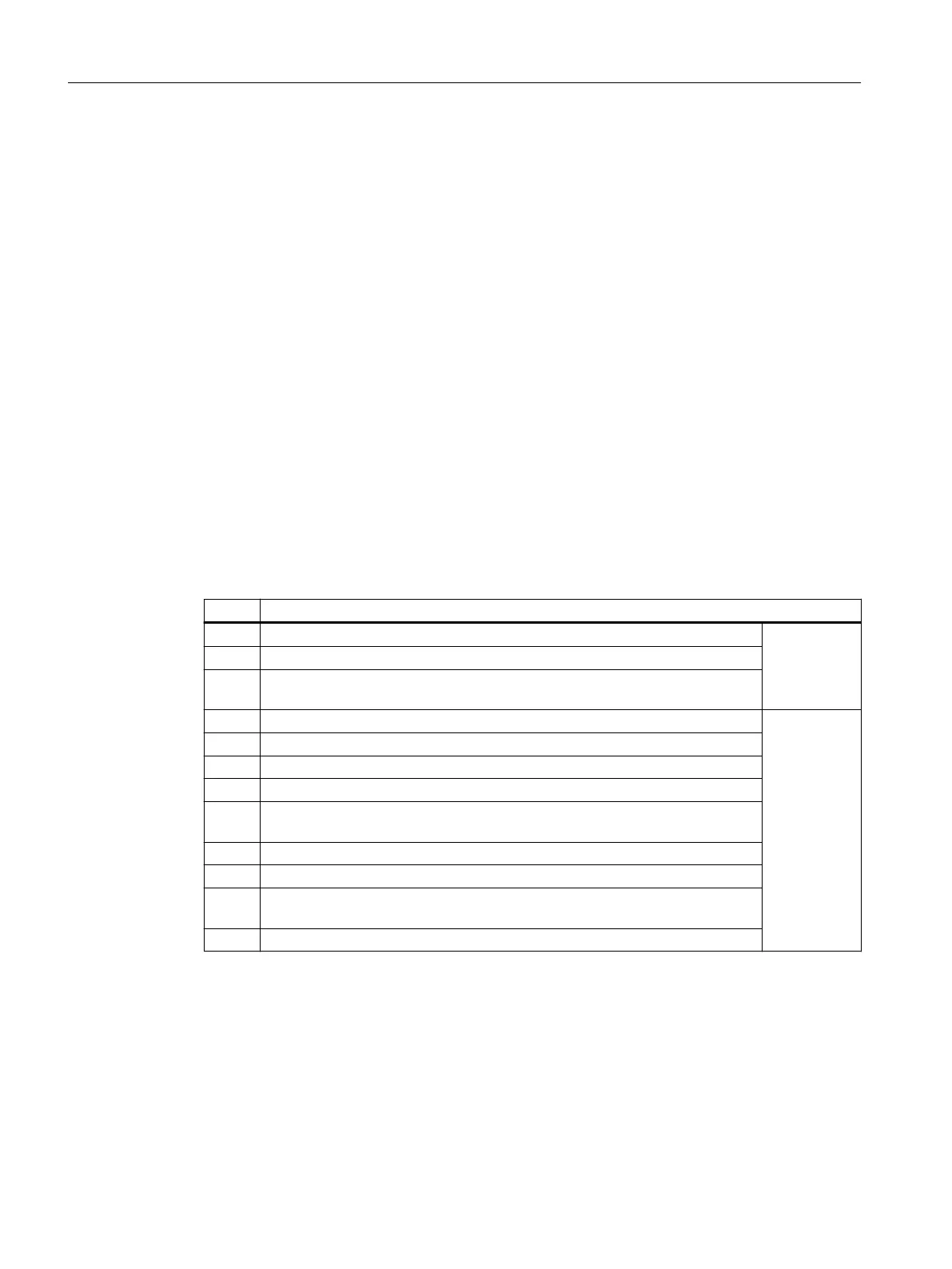

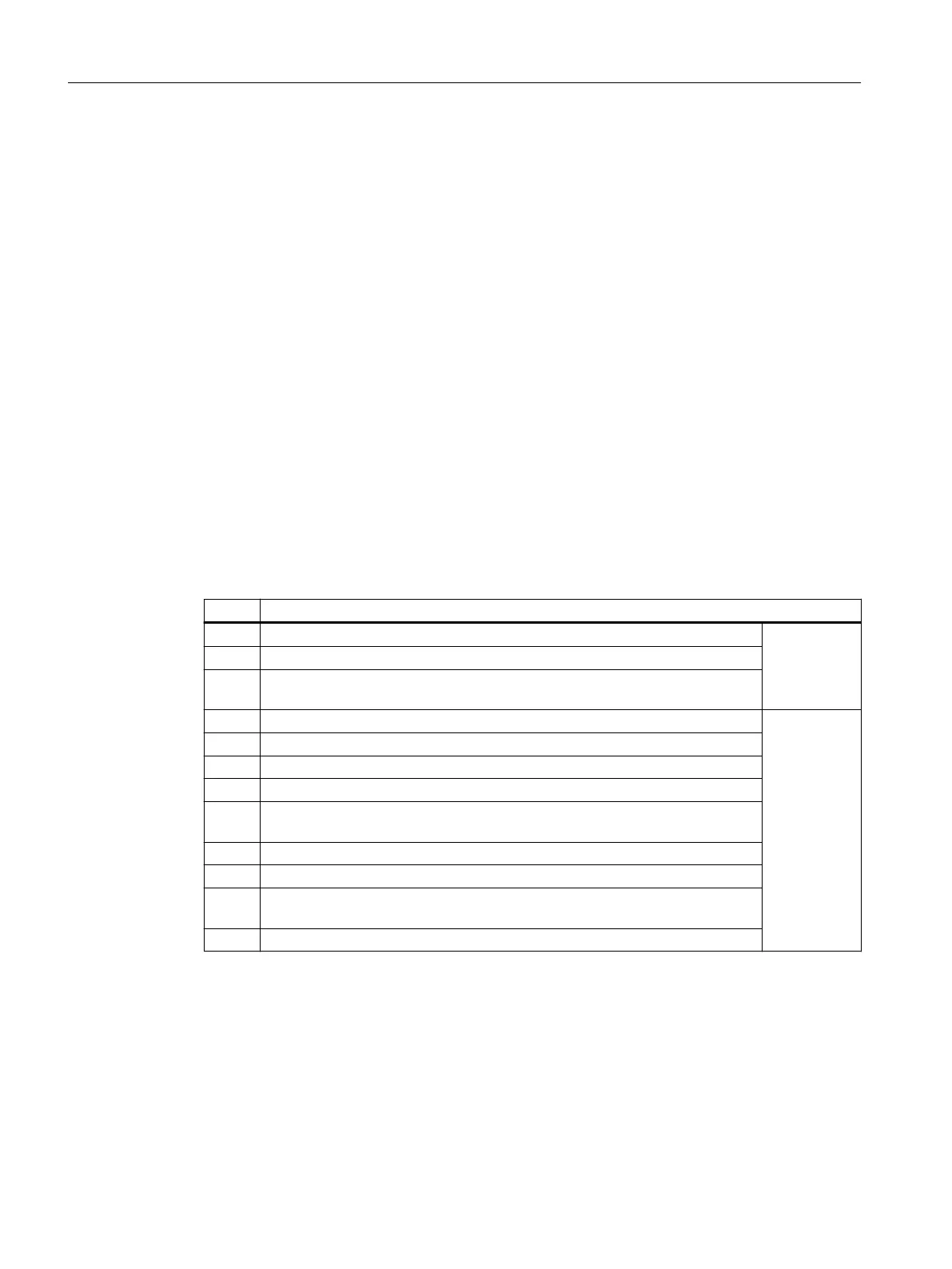

Table 5-1 Conguration sequence

step Description of the conguring activity

1. Clarify the drive type See the next

chapter

2. Dene the constraints and incorporate them into the automation system

3. Dene the load case, calculate the maximum load torque and determine the

motor

4. Dene the converter required See

catalog

5. Repeat steps 3 and 4 for additional axes

6. Determine line-side power options (main switch, fuses, line lters, etc.)

7. Dene other system components (e.g. braking resistors)

8. Calculate the current demand of the components for the 24 V DC power supply

- and specify the power supplies (SITOP devices, Control Supply Modules)

9. Determine the connection system components

10. Congure the drive line-up components

11. Calculate the required cable cross sections for power supply and motor con‐

nections

12. Inclusion of mandatory installation clearances

Observe also the recommended combinations of converters and motors with the associated

connecting cables in the Chapters "Motor overview / Assignment Motor modules / Power cables

(Page 85)".

Conguration

5.2 Conguring procedure

1FK2 Synchronous Motors for SINAMICS S120

66 Conguration Manual, 02/2022, A5E46927724B AD

Loading...

Loading...