9.4 Preventive maintenance

9.4.1 Inspection

The purpose of an inspection is to ascertain and evaluate the current status of the equipment.

An inspection mainly comprises visual checks. Inspections should be carried out based on a

schedule that meets the needs of the special ambient conditions at the location of use. The

following servicing and inspection instructions are used as the basis for regular inspection of

the equipment.

9.4.2 Checklist for preventive maintenance work

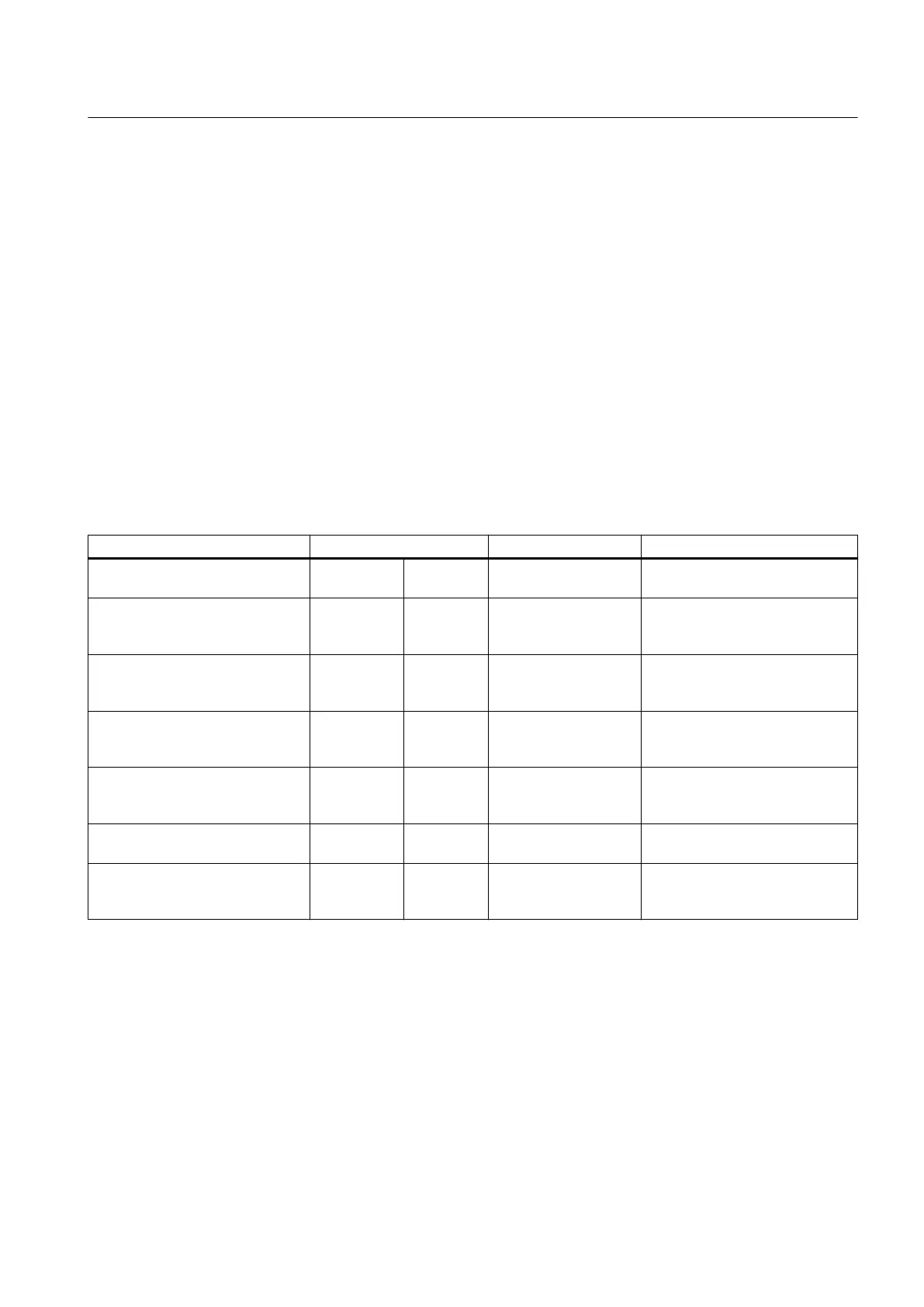

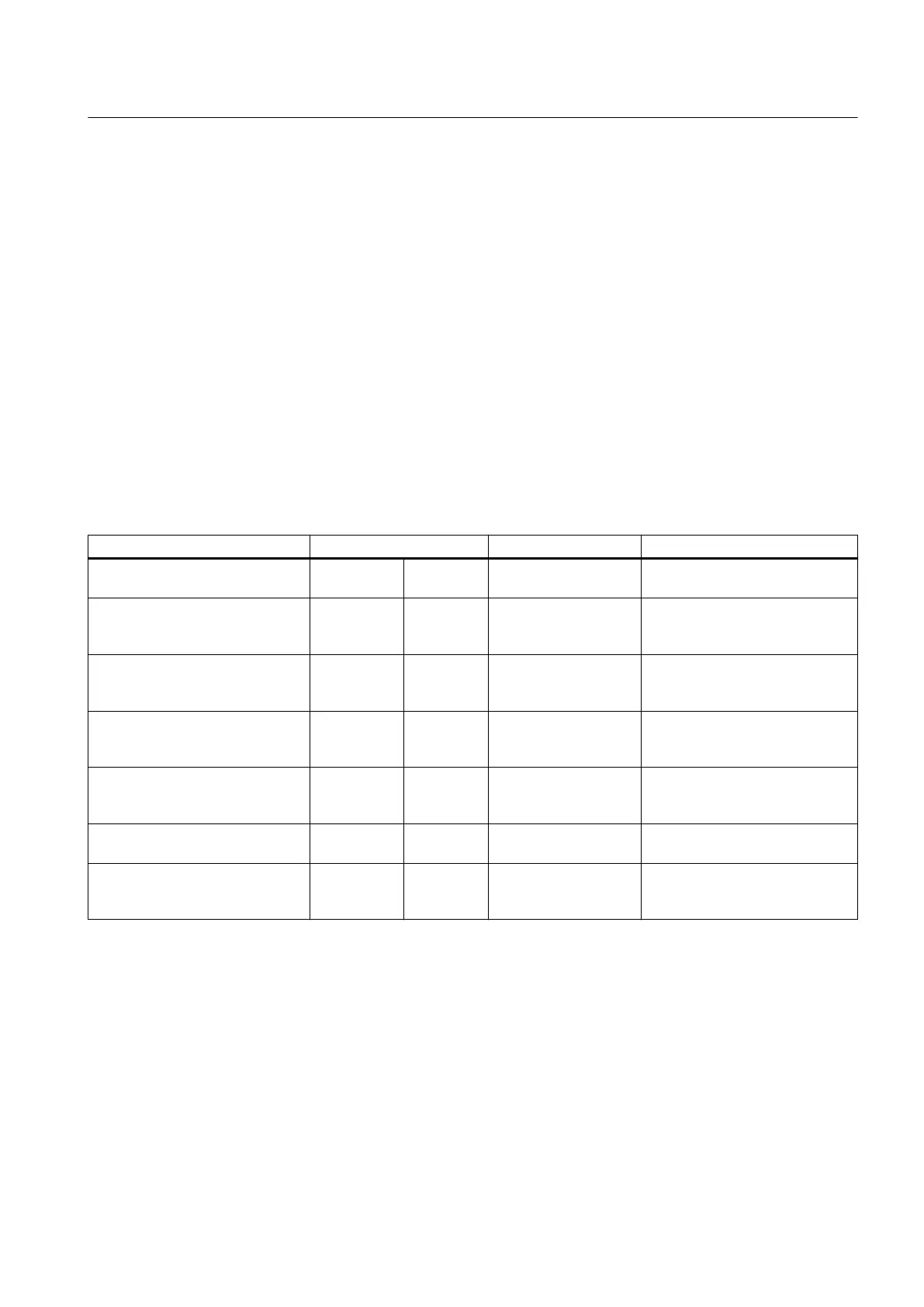

Table 9-1 General checklist for preventive maintenance work

Maintenance Carried out by: Frequency Comments

Clean the cabinet (exterior). Owner As required Visual inspection, clean if re‐

quired.

Clean the cabinet (interior). Siemens

service per‐

sonnel

Annually Visual inspection, clean if re‐

quired.

Check the external connections. Owner After one year, and ev‐

ery four years there‐

after

Inspecting the cable clamps and

screw terminals.

Check the internal connections. Siemens

service per‐

sonnel

After one year, and ev‐

ery four years there‐

after

Perform inspection and visual in‐

spection.

Siemens

service per‐

sonnel

Annually See the specifications in the Op‐

erating Instructions.

Check the cooling system. Owner After 30,000 operating

hours

See the specifications in the Op‐

erating Instructions.

Check the spare parts. Siemens

service per‐

sonnel

Annually If necessary reorder spare parts.

Maintenance

9.4 Preventive maintenance

SINAMICS PERFECT HARMONY GH150 6SL3825

Operating Instructions 05/2020 95

Loading...

Loading...