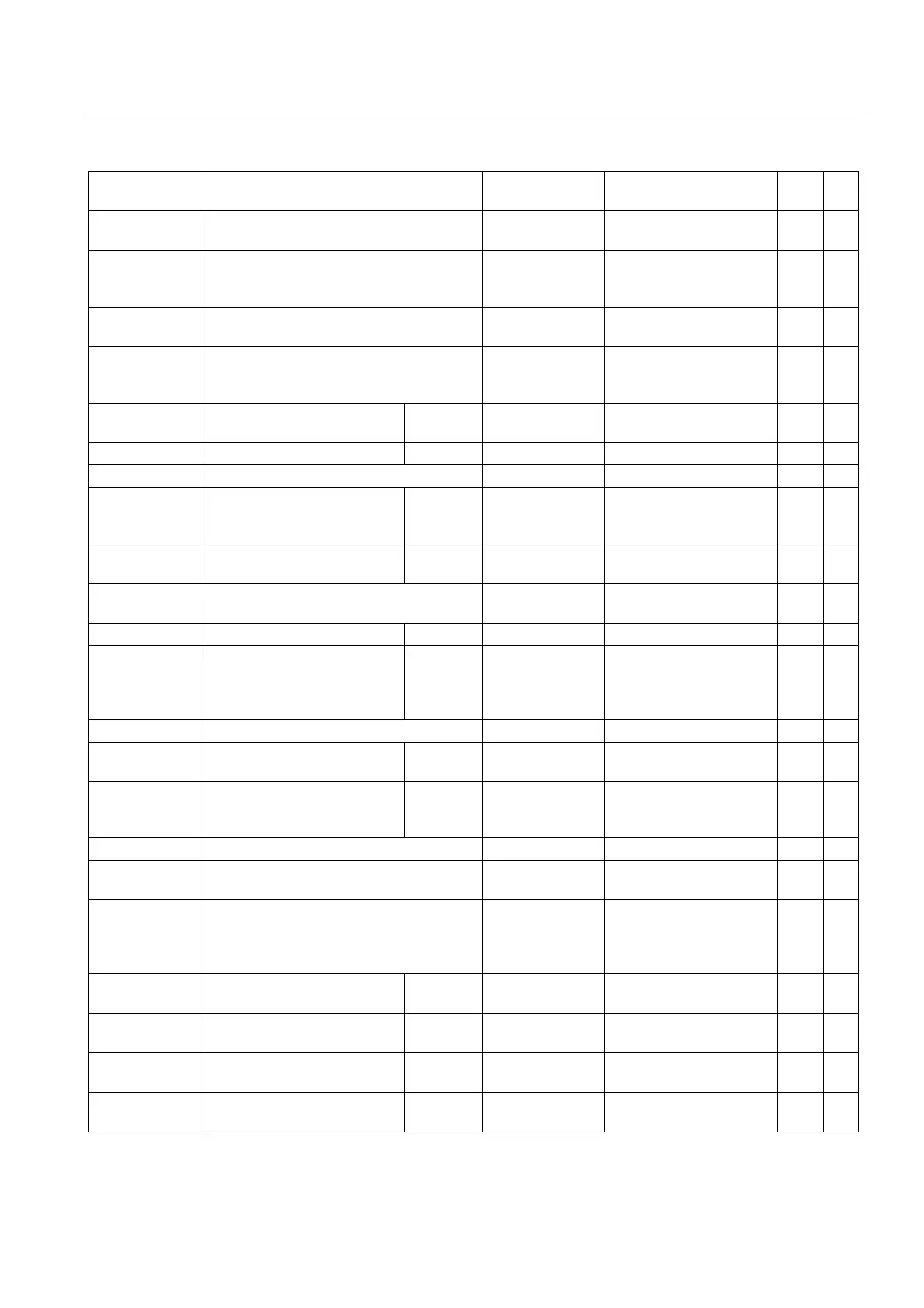

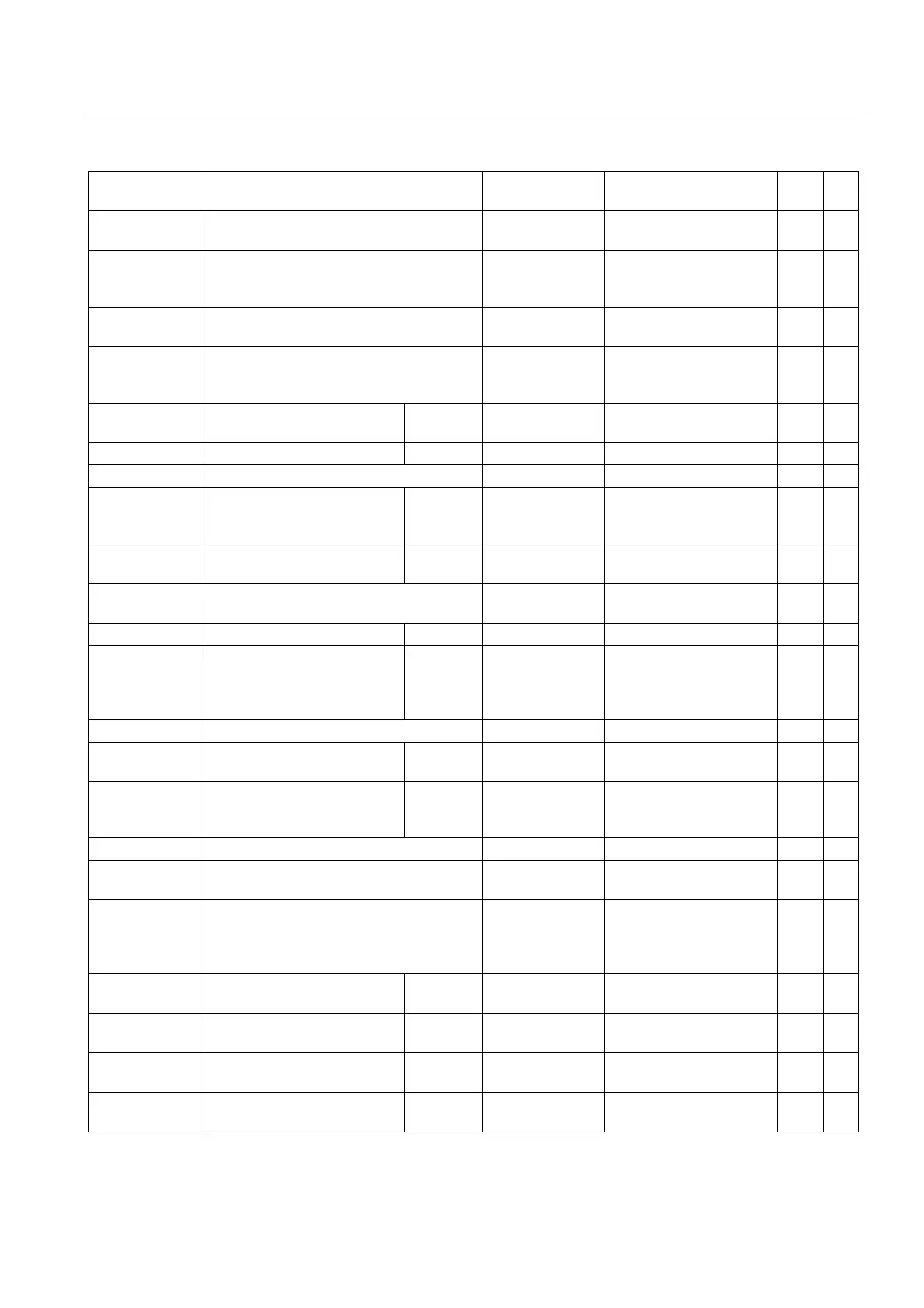

Tables

15.1 List of statements

Job planning

Programming Manual, 03/2006 Edition, 6FC5398-2BP10-1BA0

15-25

ORIVIRT1

Orientation angle via virtual orientation

axes (definition 1)

m 50

ORIVIRT2 Orientation angle via virtual orientation

axes (definition 1)

m 50

ORIMKS

6

Tool orientation in the workpiece

coordinate system

m 25

ORIRESET Initial setting of tool orientation with up to 3

orientation axes

Parameter

optional (REAL)

ORIRESET(A,B,C)

ORIWKS

1,6

Tool orientation in the workpiece

coordinate system

m 25

OS Oscillation ON / OFF

Integer,

w/o signs

OSB Oscillating: Start point m

OSC

6

Continuous tool orientation smoothing m 34

OSCILL Axis assignment for

oscillation-

activate oscillation

Axis: 1 –

infeed axes

m

OSCTRL Oscillation control options Integer,

w/o signs

M

OSD

6

Rounding of tool orientation by specifying

rounding length with SD

Block-internal m 34

OSE Oscillating: End point m

OSNSC Oscillating: Number of spark-

out cycles

(oscillating: number spark out

cycles)

m

OSOF

1,6

Tool orientation smoothing OFF m 34

OSP1 Oscillating: Left reversal point

(oscillating: position 1)

Real m

OSP2 Oscillating: Right reversal

point

(oscillating: position 2)

Real m

OSS

6

Tool orientation smoothing at end of block m 34

OSSE

6

Tool orientation smoothing at start and end

of block

m 34

OST

6

Rounding of tool orientation by specifying

angle tolerance in degrees with SD

(maximum deviation from programmed

orientation characteristic)

Block-internal m 34

OST1 Oscillating: Stopping point in

left reversal point

Real m

OST2 Oscillating: Stopping point in

right reversal point

Real m

OVR Speed override 1, ...,

200%

m

OVRA Axial speed override 1, ...,

200%

m

Loading...

Loading...