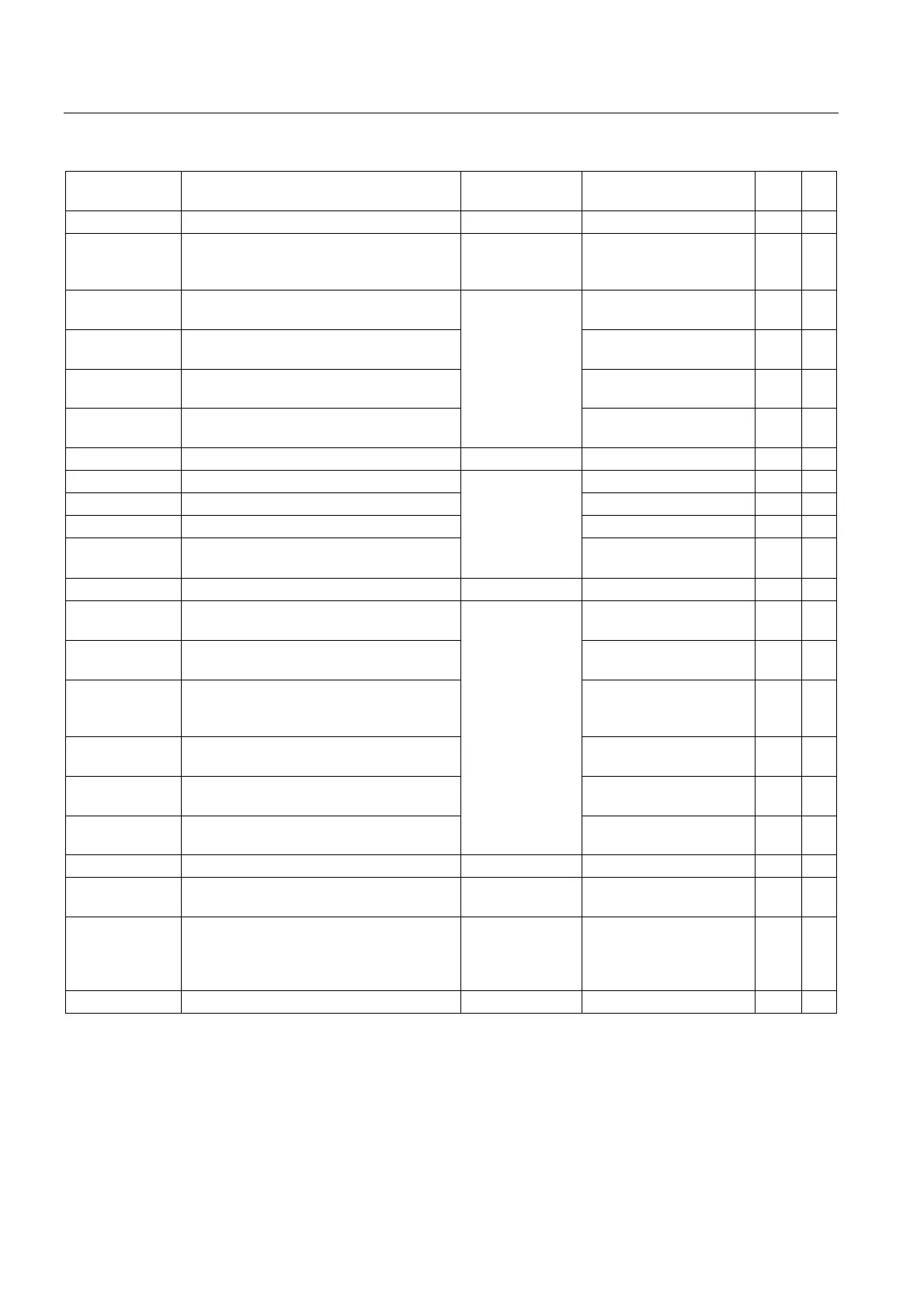

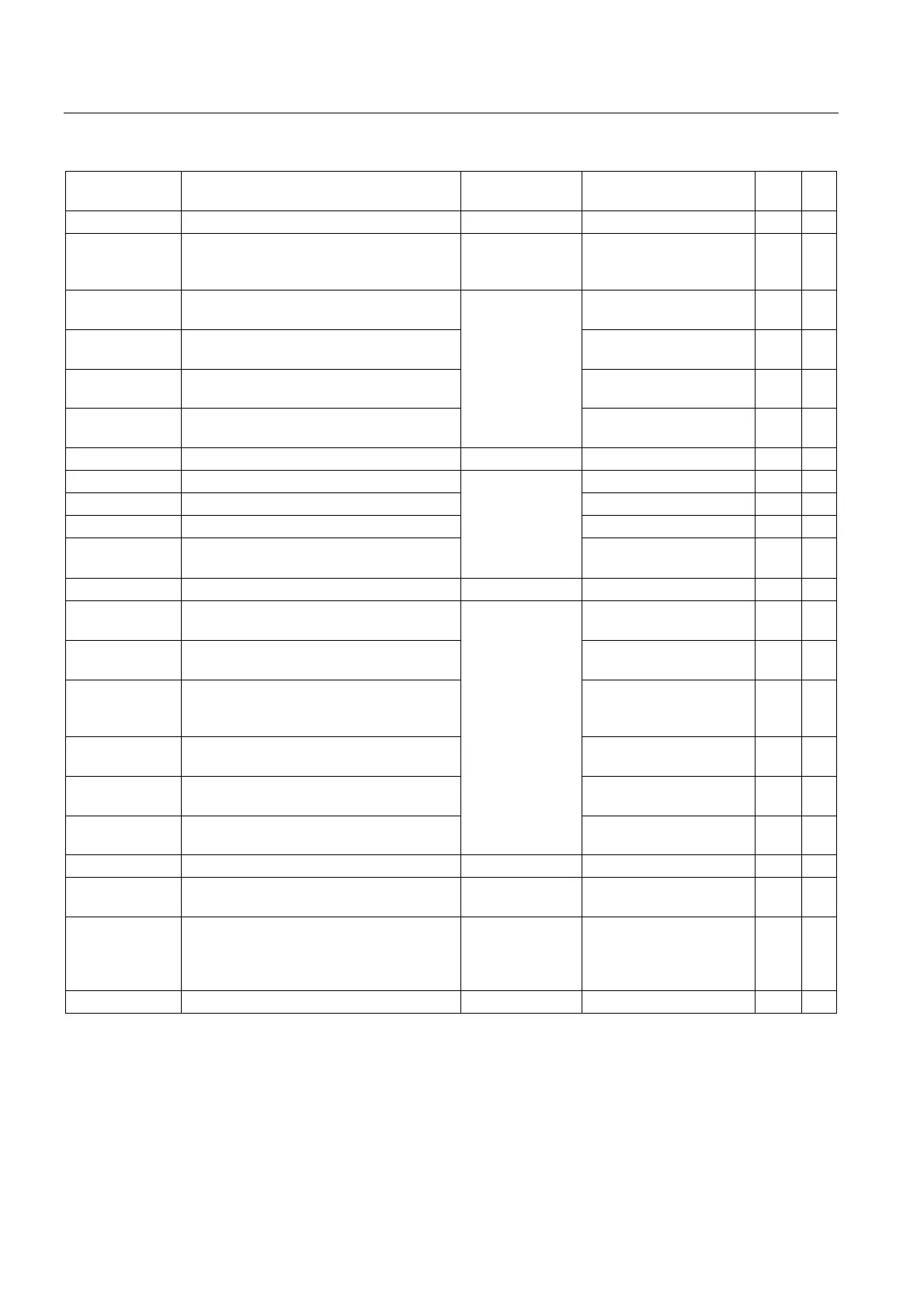

Tables

15.1 List of statements

Job planning

15-34 Programming Manual, 03/2006 Edition, 6FC5398-2BP10-1BA0

TO

Defines the end value in a FOR counter

loop

TOFFOF Deactivate on-line tool offset

TOFFON Activate online tool length compensation

(Tool Offset ON)

Specify a 3D

offset direction

TOFFON (Z, 25) with

offset direction Z

offset value 25

TOFRAME Set current programmable frame to tool

coordinate system

m 53

TOFRAMEX X axis parallel to tool direction, secondary

axis Y, Z

m 53

TOFRAMEY Y axis parallel to tool direction, secondary

axis Z, X

m 53

TOFRAMEZ Z axis parallel to tool direction, secondary

axis X, Y

Frame rotations

in the tool

direction

m 53

TOFROF Frame rotations in the tool direction OFF m 53

TOFROT Z axis parallel to tool orientation m 53

TOFROTX X axis parallel to tool orientation m 53

TOFROTY Y axis parallel to tool orientation m 53

TOFROTZ Z axis parallel to tool orientation

Frame rotations

ON

Rotation

component of

programmable

frame

m 53

TOLOWER Convert letters of the string into lowercase

TOWSTD Initial setting value for corrections in tool

length

m 56

TOWBCS Wear values in basic coordinate system

BCS

m 56

TOWKCS Wear values in the coordinate system of

the tool head for kinetic transformation

(differs from MCS by tool rotation)

m 56

TOWMCS Wear values in machine coordinate system

(MCS).

m 56

TOWTCS Wear values in the tool coordinate system

(tool carrier ref. point T at the toolholder)

m 56

TOWWCS Wear values in workpiece coordinate

system (WCS)

Inclusion of tool

wear

m 56

TOUPPER Convert letters of the string into uppercase

TR Parameter for access to frame data:

Translation

TRAANG Transformation inclined axis Several

transformations

can be set for

each channel

TRACEOF Circularity test: Transfer of values OFF

Loading...

Loading...