12.95

4.3 Measuring system

4-74

E Siemens AG, 2002. All rights reserved

SINUMERIK 810D Manual Hardware Configuration (PHC) -- 11.02 Edition

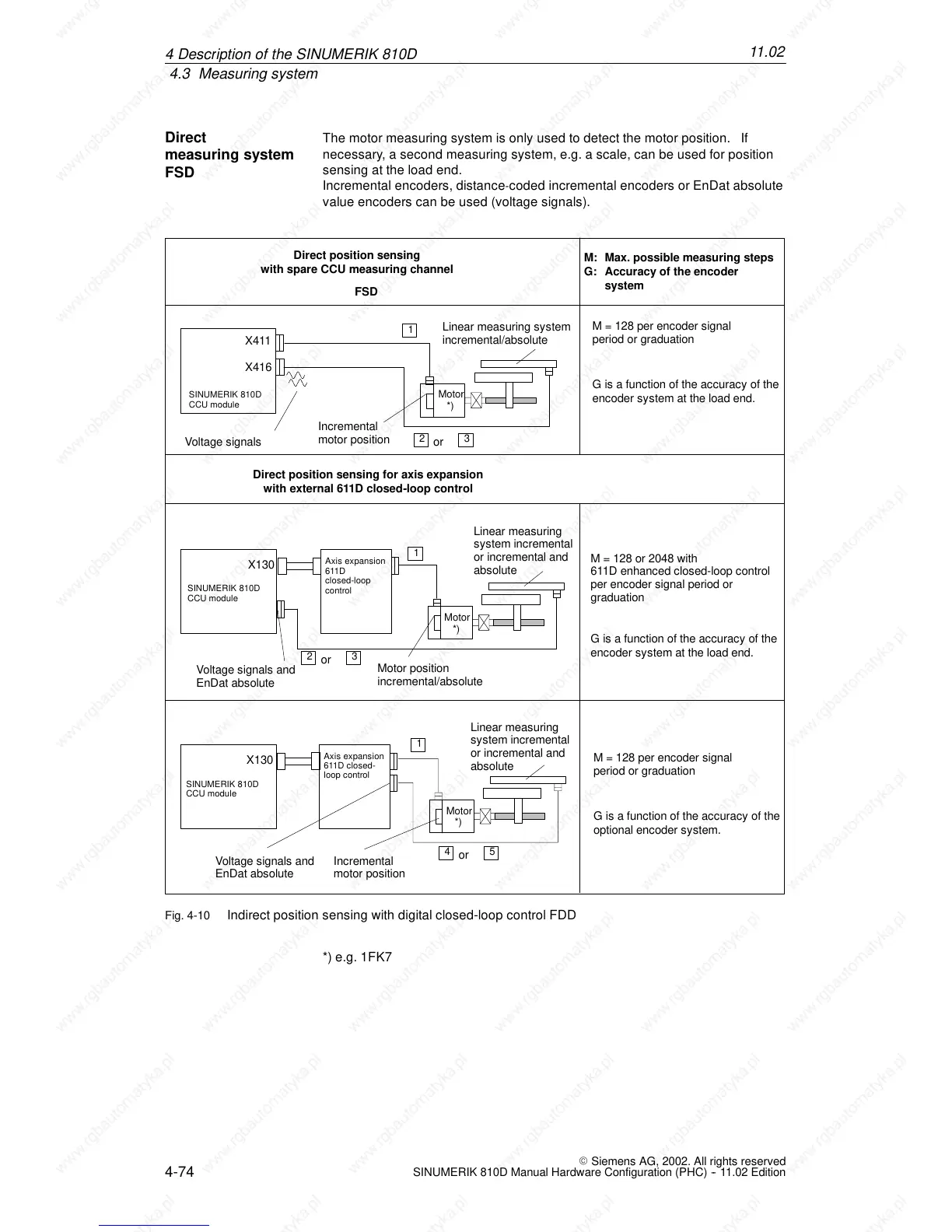

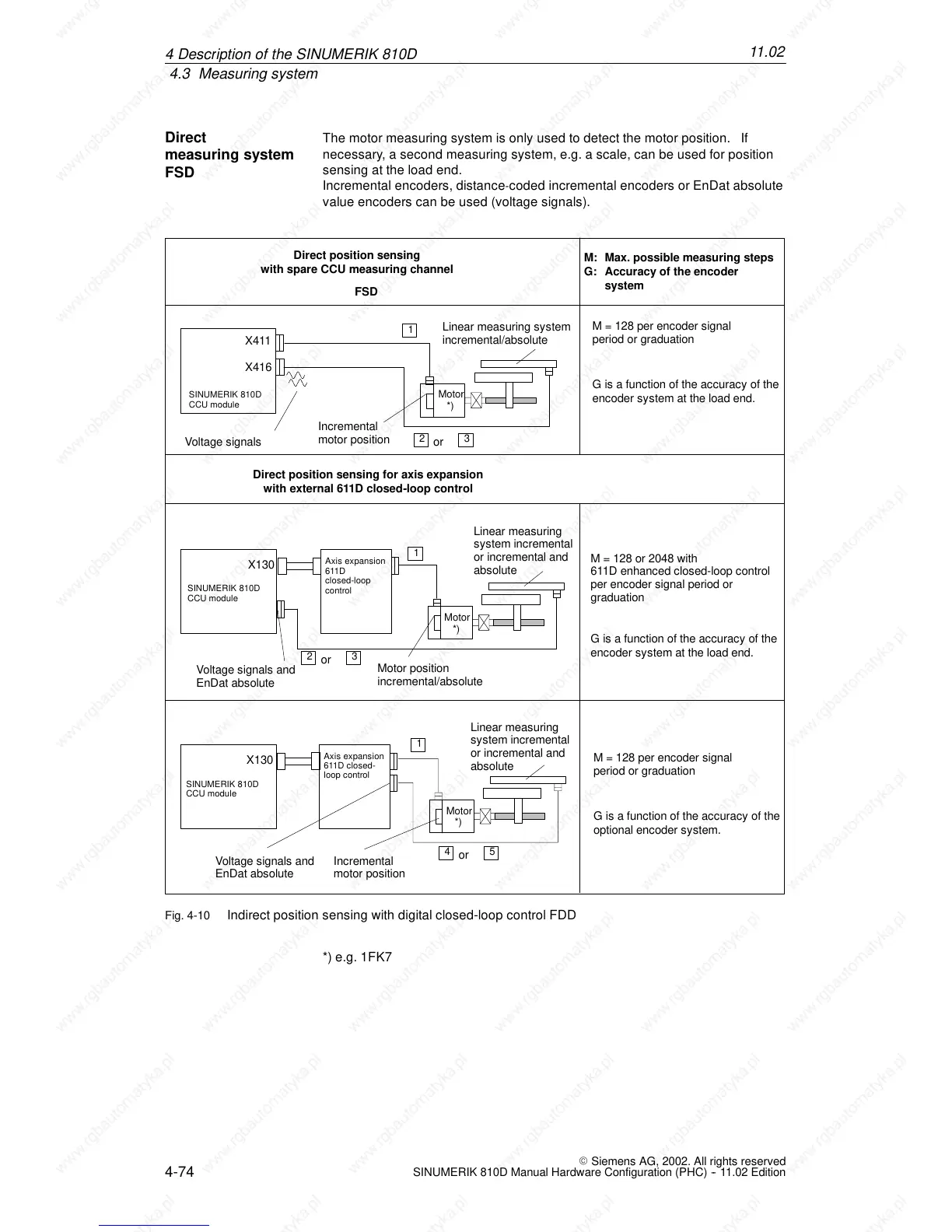

The motor measuring system is only used to detect the motor position. If

necessary, a second measuring system, e.g. a scale, can be used for position

sensing at the load end.

Incremental encoders, distance

-coded incremental encoders or EnDat absolute

value encoders can be used (voltage signals).

M: Max. possible measuring steps

G: Accuracy of the encoder

system

Direct position sensing

with spare CCU measuring channel

Motor

*)

Linear measuring system

incremental/absolute

Voltage signals

X411

X416

M = 128 per encoder signal

period or graduation

G is a function of the accuracy of the

encoder system at the load end.

SINUMERIK 810D

CCU module

Axis expansion

611D

clos ed-loop

control

X130

SINUMERIK 810D

CCU module

Axis expansion

611D clos ed-

loop control

X130

Motor

*)

Linear measuring

system incremental

or incremental and

absolute

Motor

*)

SINUMERIK 810D

CCU module

Motor position

incremental/absolute

Incremental

motor position

Incremental

motor position

Linear measuring

system incremental

or incremental and

absolute

Direct position sensing for axis expansion

with external 611D closed-loop control

Voltage signals and

EnDat absolute

Voltage signals and

EnDat absolute

M = 128 or 2048 with

611D enhanced closed-loop control

per encoder signal period or

graduation

G is a function of the accuracy of the

encoder system at the load end.

M = 128 per encoder signal

period or graduation

G is a function of the accuracy of the

optional encoder system.

FSD

1

1

32

or

32

or

54

or

1

Fig. 4-10 Indirect position sensing with digital closed-loop control FDD

*) e.g. 1FK7

Direct

measuring system

FSD

4De

Loading...

Loading...