11.90 4 Monitoring Functions

4.6 Listing of the alarms/alarm description

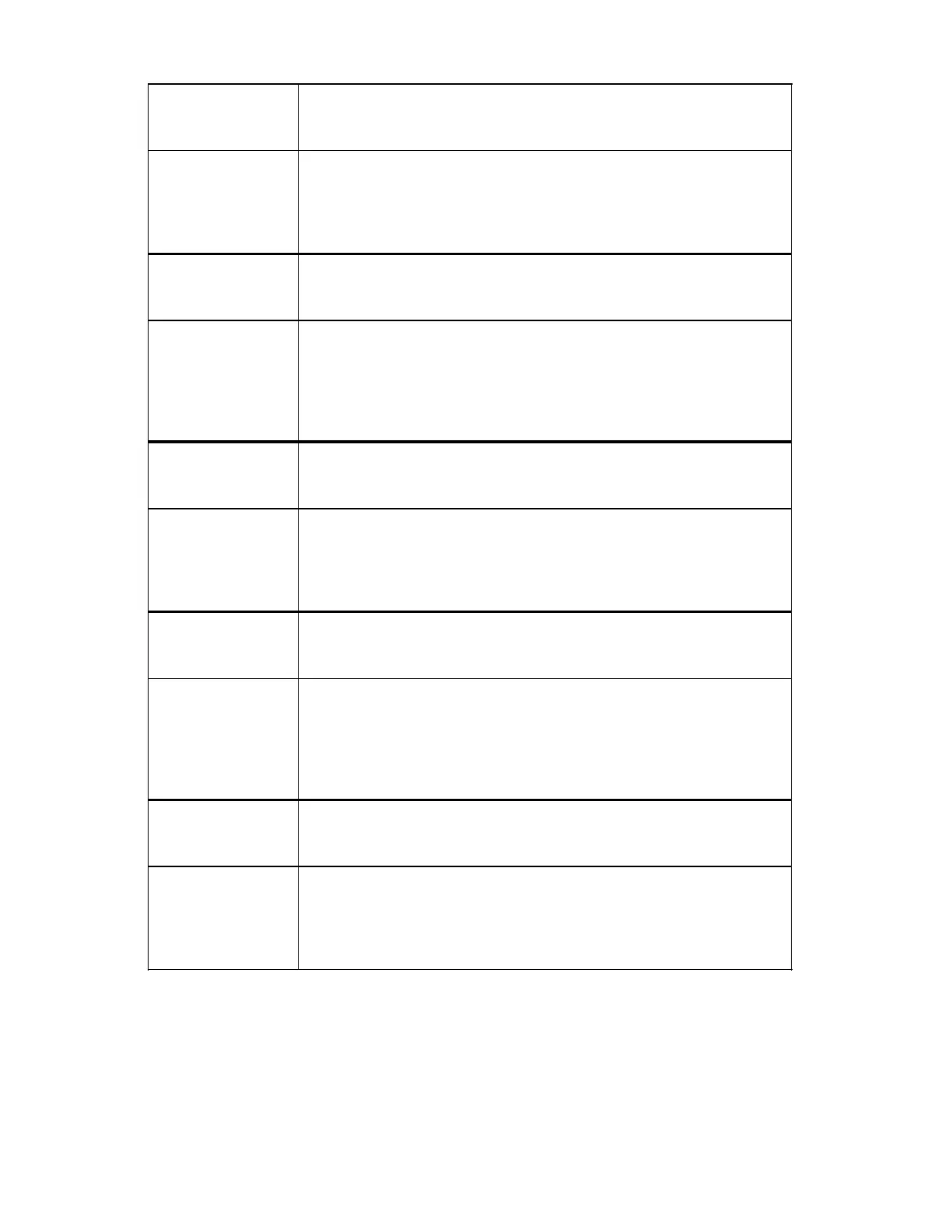

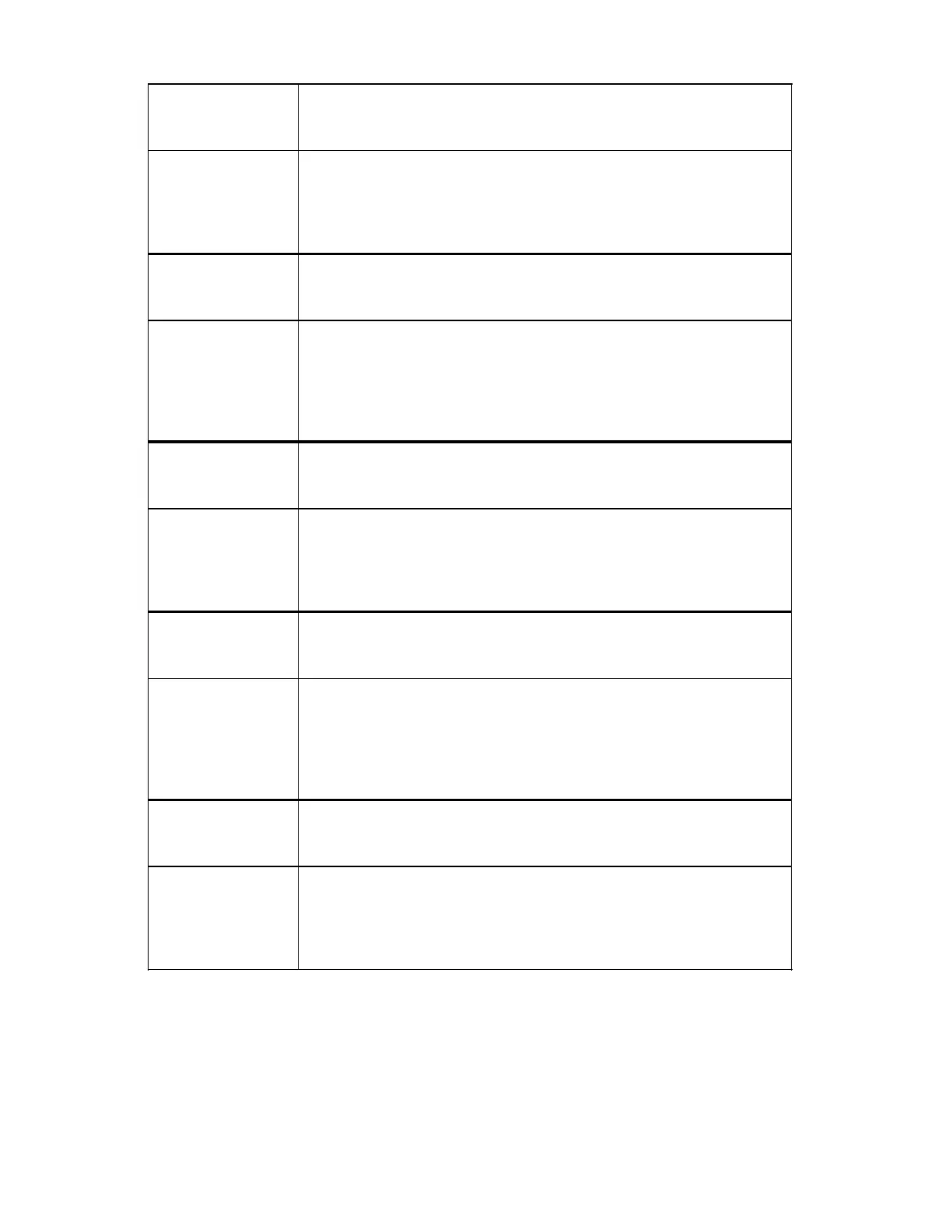

Alarm No.

Alarm Text:

160

*

”Drift too high”

Reason:

Effect:

Remedy:

The drift to be corrected by the NC is too high

– Inhibiting of NC START

– The green ”Position not yet reached ”LED lights up

– No traverse movement possible

Execute drift compensation (Service)

Alarm No.

Alarm Text:

168

*

”Servo enable, trav. axis”

Reason:

Effect:

Remedy:

The axis-specific servo enable signal was removed by the PLC user

program during traversing.

Inhibiting of NC START

Operation is brought to a definer stop

Follow-up operation

Report the problem to Service

Alarm No.

Alarm Text:

172

*

/176

*

”+* / –* Working area limit”

Reason:

Effect:

Remedy:

Explanation:

The set working area limits have been reached

Inhibiting of NC START

– Check the program

– Check the working area limits in setting data.

Working area limits in ”JOG” mode are set in a machine data

Alarm No.

Alarm Text:

180

*

”Axis in several channels”

Reason:

Effect:

Remedy:

With two program running simultaneously in different channels, one

axis was programmed in both programs (channels), causing a

traversing movement for the related axis to be output for both

programs.

Inhibiting of NC START

Check both programs

Alarm No.

Alarm Text:

184

*

”Stop behind ref. point”

Reason:

Effect:

Remedy:

When traversing to reference point, the axis was stopped between the

reference cam and the zero mark of the measuring system

– Inhibiting of NC START

– Reference point not reached

Approach reference point again

”

*

” stands for: ”0” = axis 1, ”1” = axis 2, ”2” = axis 3, ”3” = axis 4, ”4” = axis 5.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EQ02 4-13

SINUMERIK 810M, GA3 (BN)

Loading...

Loading...