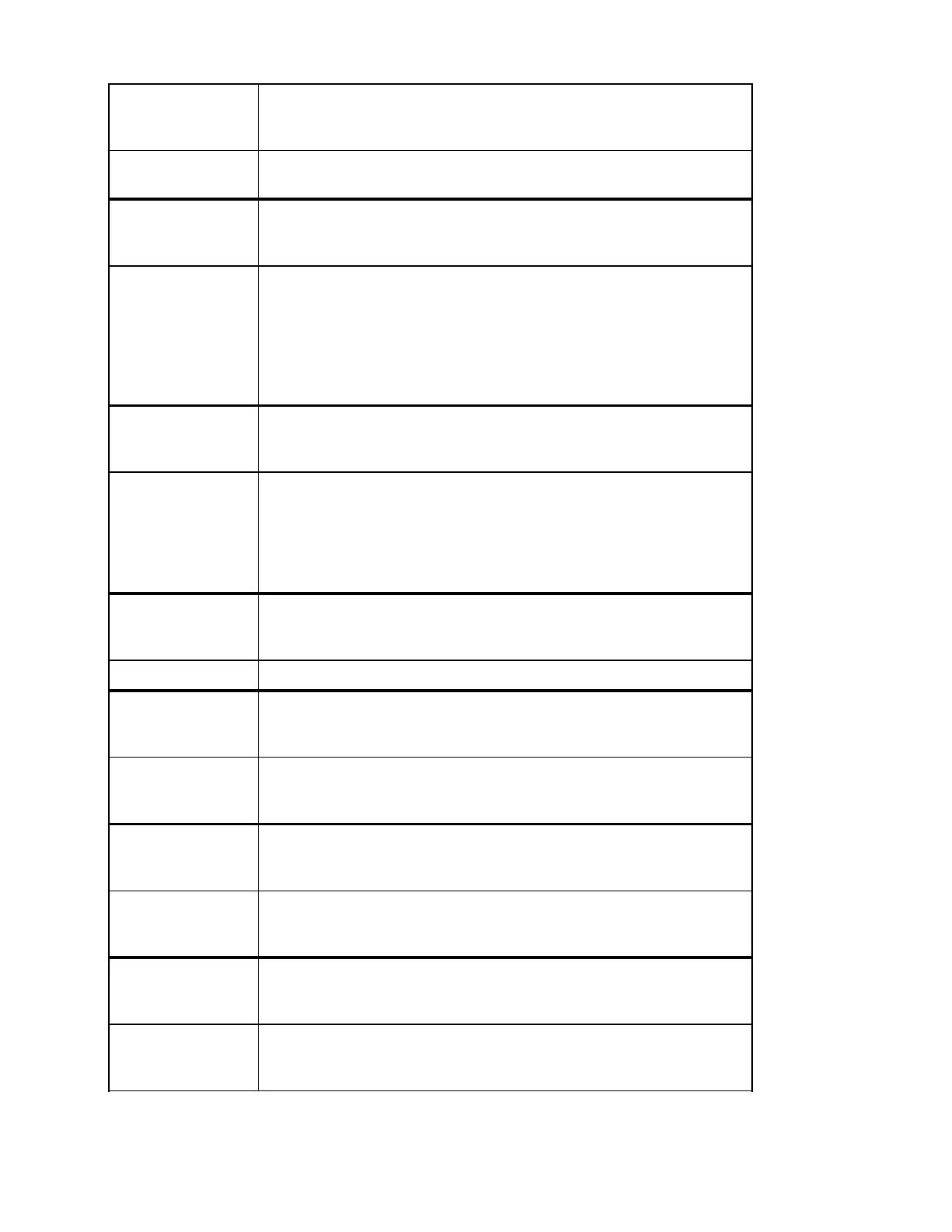

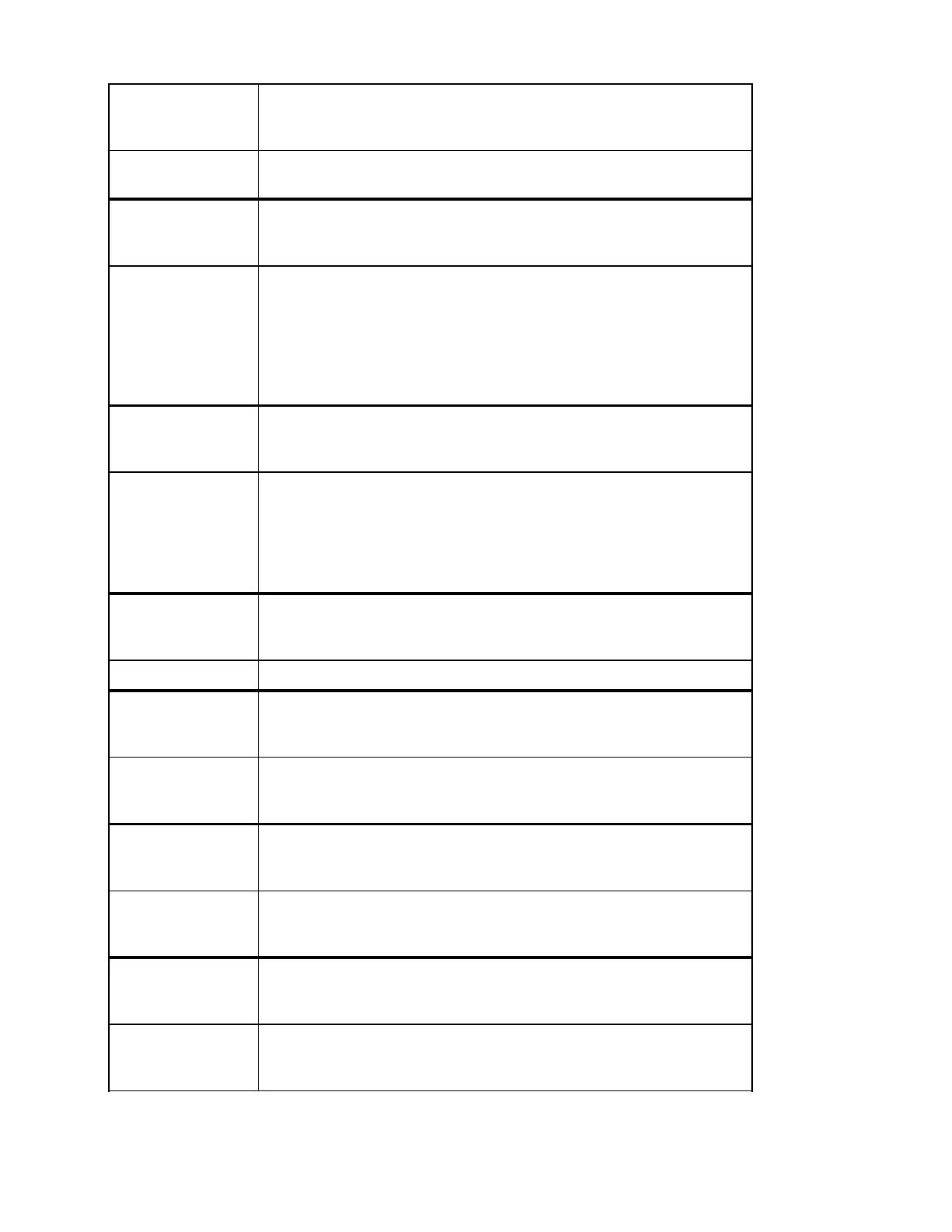

4 Monitoring Functions 01.93

4.6 Listing of the alarms/alarm description

Alarm No.

Alarm Text:

196

"Follow-up /park for axis"

Reason:

Remedy:

Spindle is not active as rotary axis.

Switch spindle to axis mode.

Alarm No.

Alarm Text:

2000

”Emergency Stop”

Reason:

Effect:

Remedy:

The EMERGENCY STOP signal is output from the PLC to the NC

Inhibiting of NC START

– Operation is brought to a defined stop

– Servo enable is removed

– Follow up operation

Check to see if the EMERGENCY STOP cam was traversed to, or if

the EMERGENCY STOP switch was operated

Alarm No.

Alarm Text:

2030

”Wrong path increment”

Effect:

Remedy:

Explanation:

– Inhibiting of NC start

– Inhibiting of NC ready

– Machining stopped.

Check the G06 block, recalculate and correct if necessary.

Distance-to-go contains an uncorrect value which does not match the

programmed contour.

Alarm No.

Alarm Text:

2031

”Eval. (weighting) factor too high (MD 388*)”

Note: Alarm only on commissioning

Alarm No.

Alarm Text:

2032

”Stop during threading”

Reason:

Effect:

During thread cutting, the feed per revolution was stopped, and the

thread destroyed

Inhibiting of NC START

Alarm No.

Alarm Text:

2034

”Speed reduction area”

Reason:

Remedy:

The software pre-limit was overshot, and the axis decelerated to the

reduced traverse rate.

Check the program

Alarm No.

Alarm Text:

2035

”Feed Limitation”

Reason:

Remedy:

The programmed feedrate is higher than the contouring feedrate,

based on the maximum feedrate of the axes.

Program a lower contouring feedrate

4-14

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EQ02

SINUMERIK 810M, GA3 (BN)

Loading...

Loading...