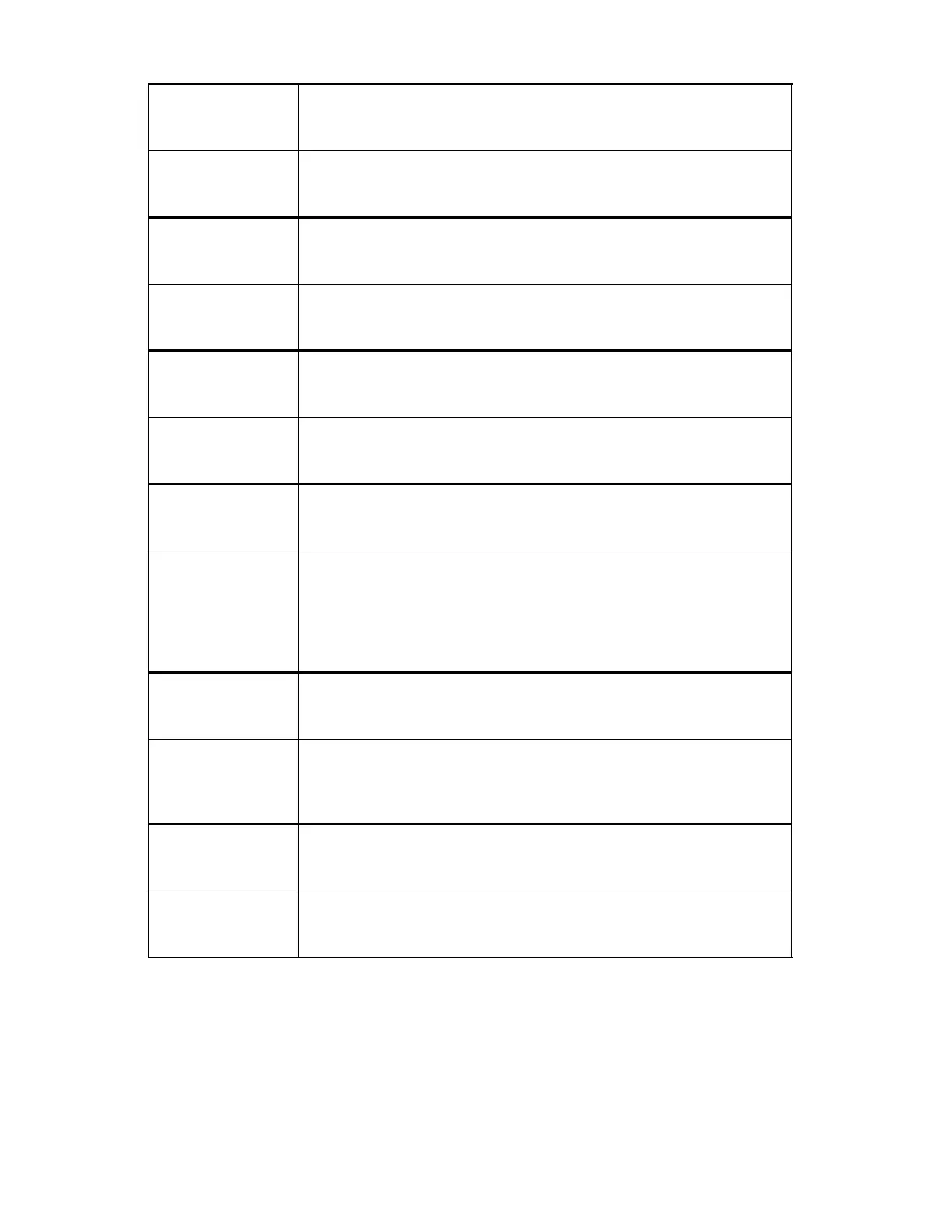

01.93 4 Monitoring Functions

4.6 Listing of the alarms/alarm description

Alarm No.

Alarm Text:

2036

”G35 thread lead decr. error”

Reason:

Remedy:

The pitch decrease in threading, is so high that at the end of the

thread, a diameter of less than, or equal to zero would result.

Program either a smaller pitch decrease or a shorter thread

Alarm No.

Alarm Text:

2037

”Programmed S value too high”

Reason:

Remedy:

The programmed spindle speed ”S” is higher than ”16 000”

Program a smaller spindle speed (the S value is limited to ”16 000”

within the control).

Alarm No.

Alarm Text:

2038

"Path feed too large"

Reason:

Effect:

Remedy:

Axis velocity too great because of the programmed path velocity.

NC START disabled and setpoint relay drops out.

Observe permissible value range.

Alarm No.

Alarm Text:

2039

”Reference point not reached”

Reason:

Effect:

Remedy:

Explanation:

Attention:

The reference point has not been traversed to in all defined axes.

Inhibiting of NC START.

Traverse the related axes to reference point.

The need to traverse to reference point can be suppressed for one or

more special axes with axis-specific machine data.

Software limits are not active for these axes.

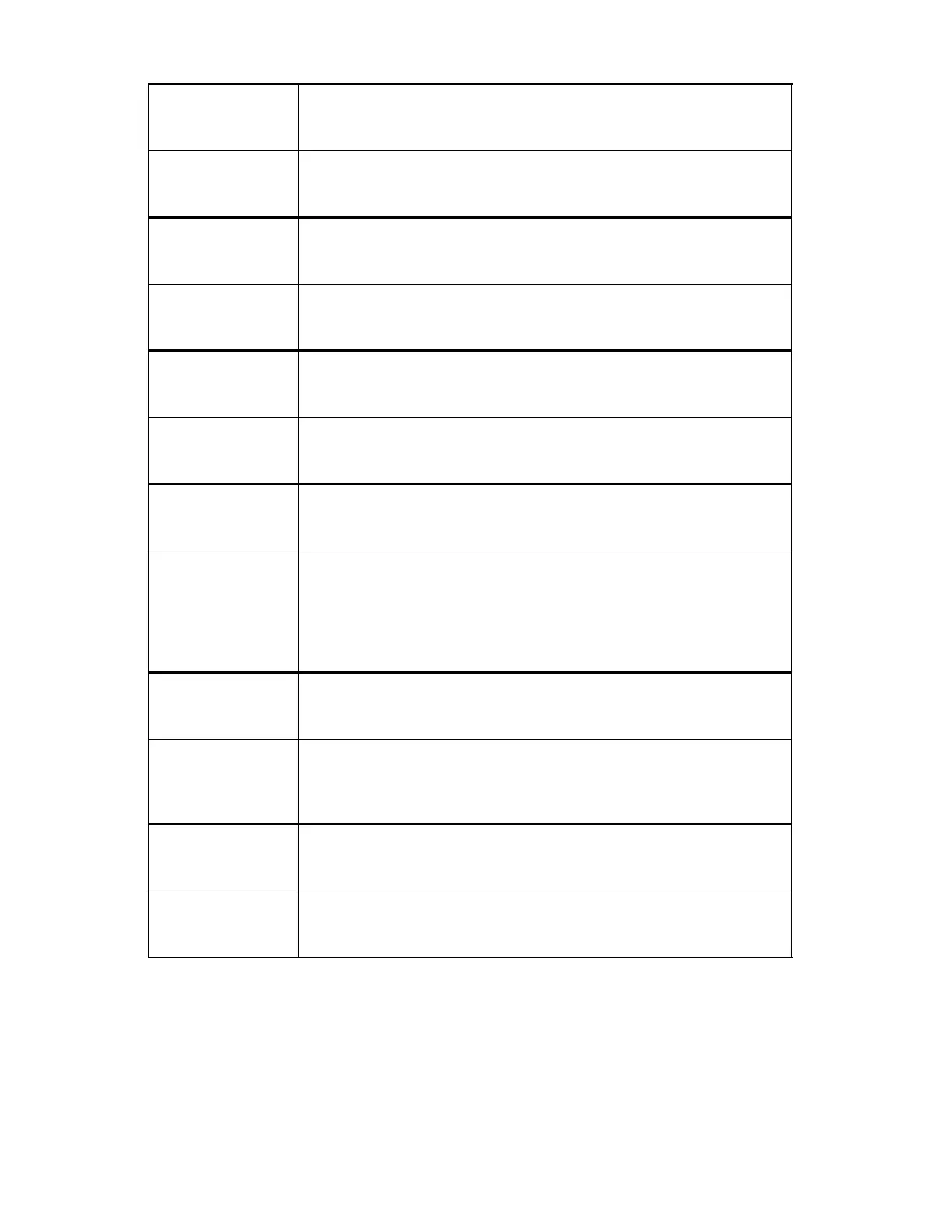

Alarm No.

Alarm Text:

2040

”Block not in memory”

Reason:

Effect:

– During block search, the required block number was not found

– During a jump in the program, the required block number could not

be found in the given direction

Inhibiting of NC START

Alarm No.

Alarm Text:

2041

”Program not in memory”

Reason:

Effect:

– The pre-selected program is not in the memory

– The subroutine called is not in the memory

Inhibiting of NC START

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EQ02 4-15

SINUMERIK 810M, GA3 (BN)

Loading...

Loading...