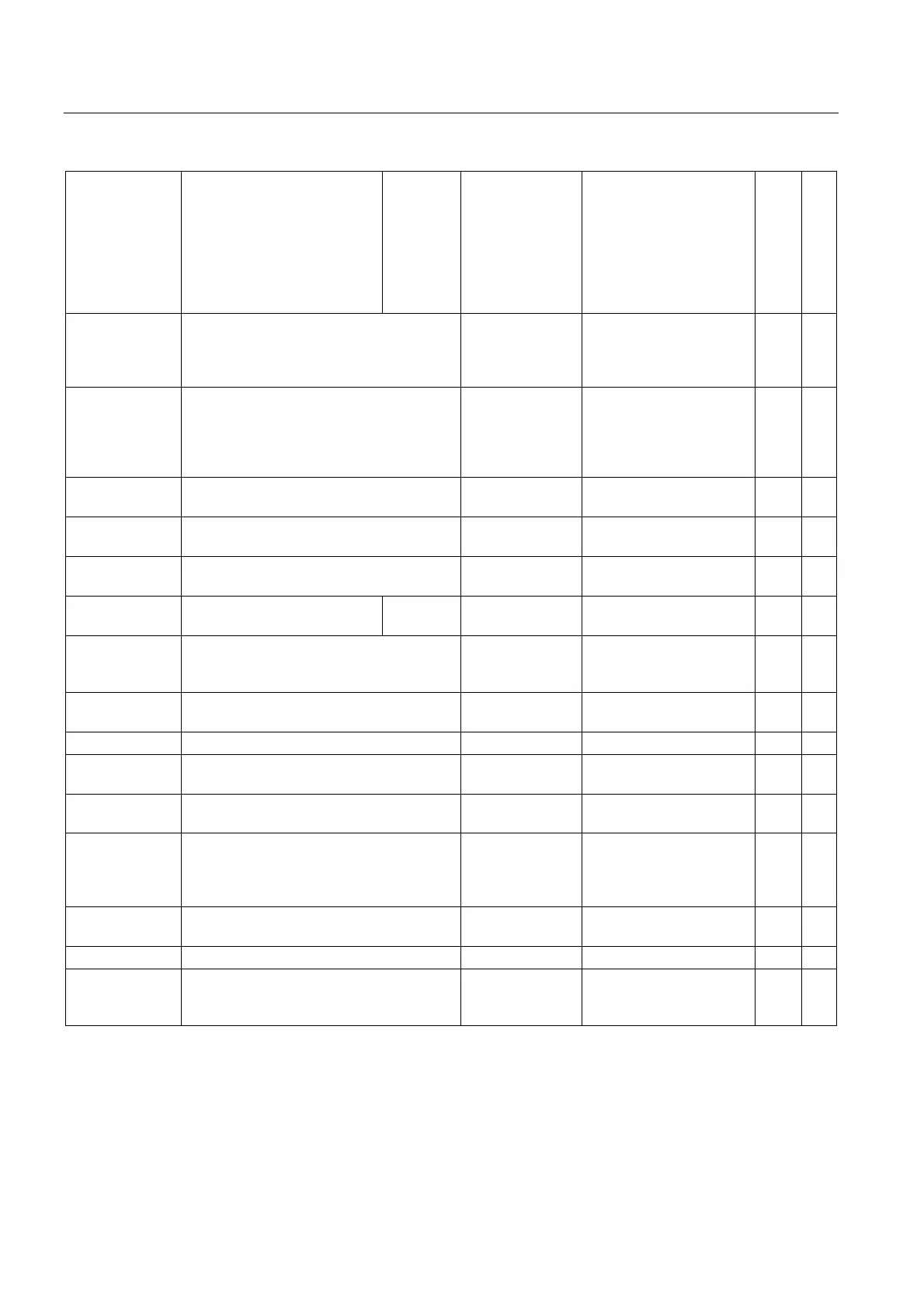

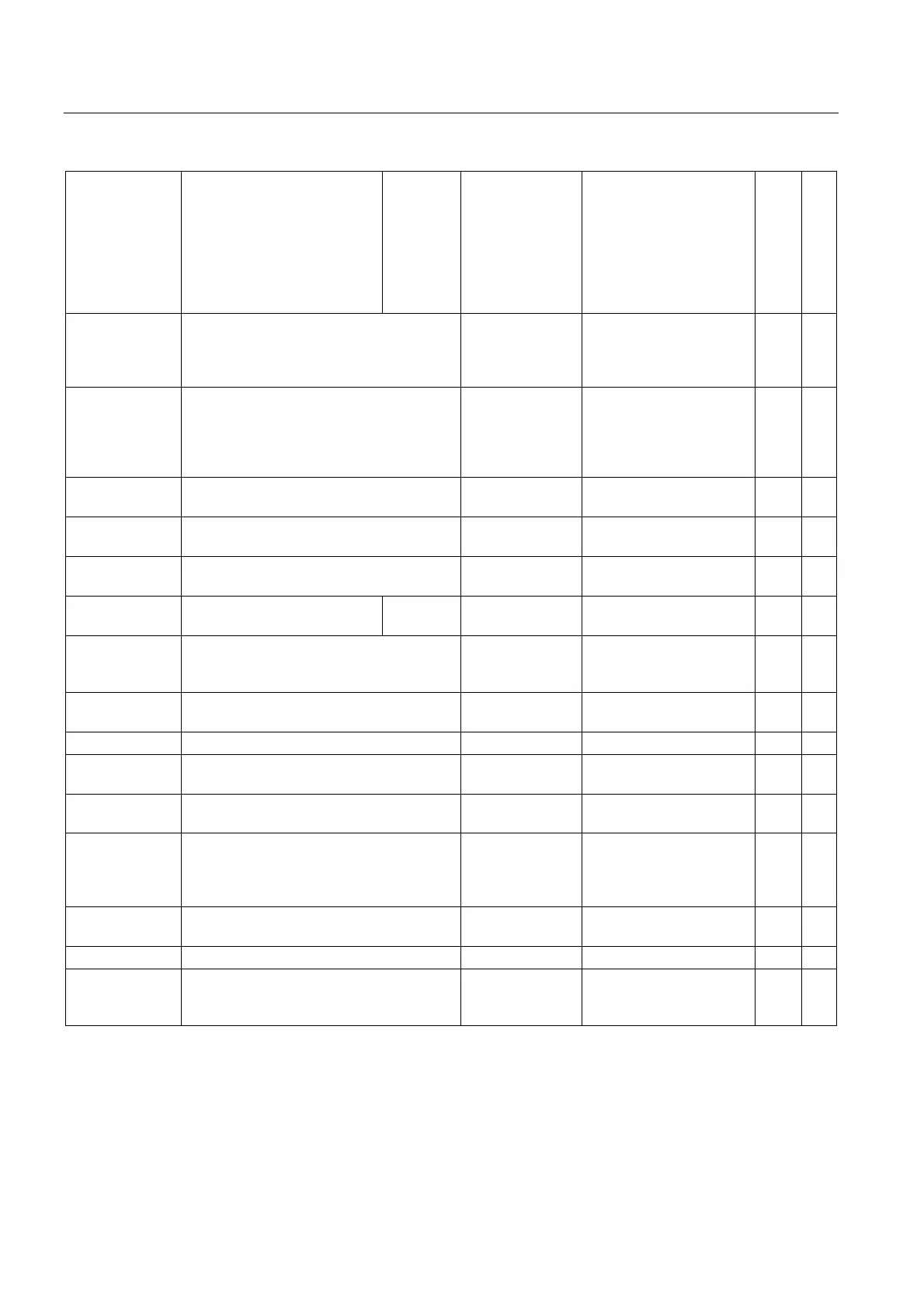

Tables

15.1 List of statements

Job planning

15-30 Programming Manual, 03/2006 Edition, 6FC5398-2BP10-1BA0

S

Spindle speed or

(with G4, G96/G961) other

meaning

0.1, ...,

99999999.

9

Spindle speed in

rpm

G4: Dwell time in

spindle

revolutions

G96/G961:

cutting speed in

m/min

S...: Speed for

master spindle

S1...: Speed for spindle 1

m, s

SAVE Attribute for saving information at

subroutine calls

The following are

saved: All modal

G functions and

the current frame

SBLOF Suppress single block

(single block OFF)

The following

blocks are

executed in

single block like a

block.

SBLON Clear single block suppression

(single block ON)

SC Parameter for access to frame data:

Scaling (scale)

SCALE50 Programmable scaling (scale) SCALE X... Y... Z...

;separate block

s 3

SD Spline degree Integer,

w/o signs

S

SEFORM Structuring instruction in Step editor to

generate the step view for HMI Advanced

Evaluated in Step

editor.

SEFORM(<section_name

>, <level>,

<icon> )

SET Keyword for initialization of all elements of

an array with listed values

SET(value, value, ...) or

DO ARRAY[n, m]=SET( )

SETAL Set alarm

SETDNO Set D number of tool (T) and its cutting

edge to new

SETINT Define which interrupt routine is to be

activated when an NCK input is present

Edge 0 → 1

is analyzed

SETM Set one/several markers for channel

coordination

Machining in the

local channel is

not influenced by

this.

SETMS Reset to the master spindle defined in

machine data

SETMS(n) Set spindle n as master spindle

SETPIECE Set piece number for all tools assigned to

the spindle.

Without spindle

number: Valid for

master spindle

Loading...

Loading...