Operation

137

SIPAR T PS2 Manual

A5E00074631--06

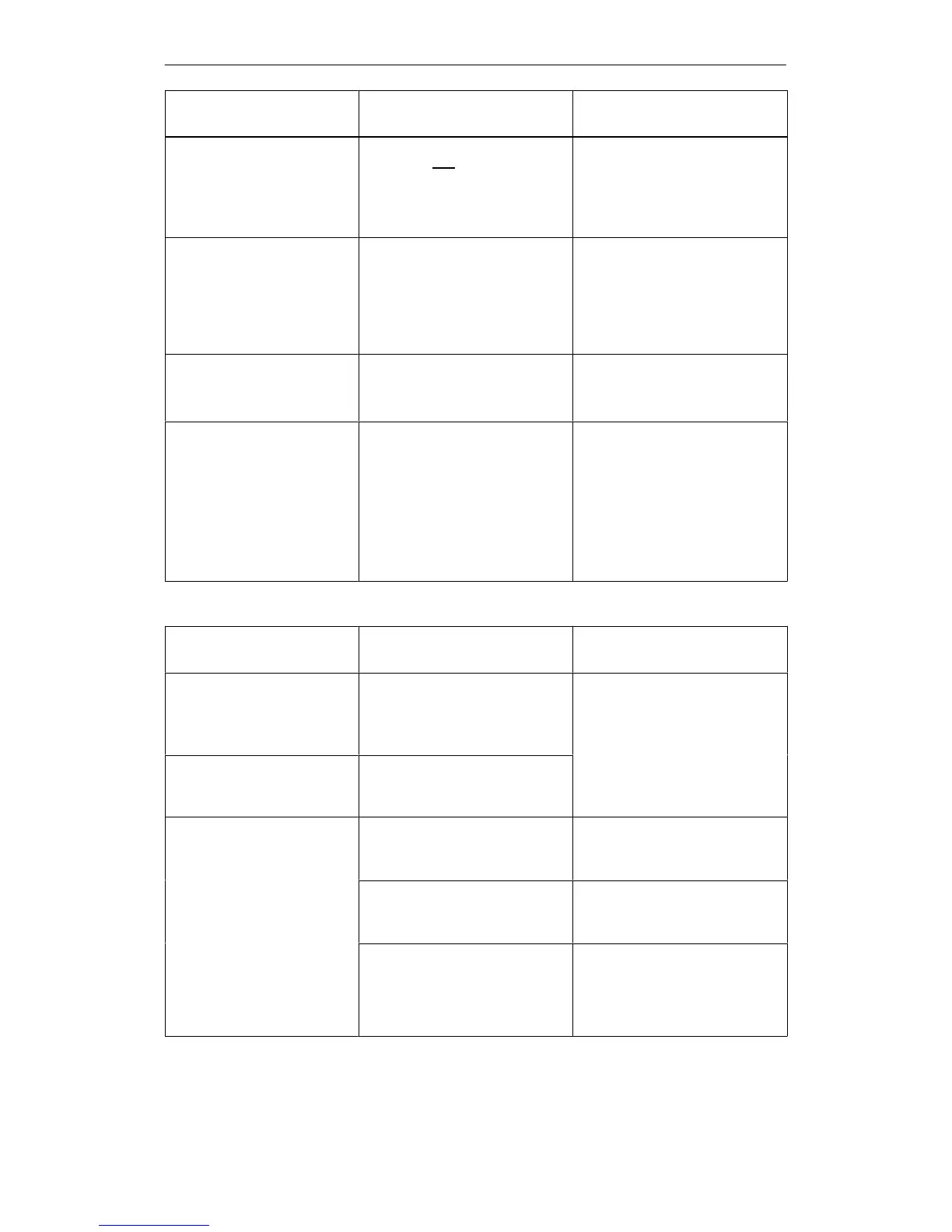

Fault indication

(symptoms)

possible cause(s) Remedies

• SIPART PS2 stops during

“RUN 1”.

• Initialization started from end

position

and

• reaction time of max. 1 min.

not waited for.

• Mains pressure not connected

or insufficient.

• Up to 1 min. delay time

required.

• Do not start initialization from

end position.

• Secure the mains pressure.

• SIPART PS2 stops during

“RUN 2”.

• Transmission ratio selector and

parameter 2 (YAGL) as well as

actual stroke do not match.

• Stroke not correctly set for

lever.

• Piezo valve(s) do(es) not

switch (see table 6).

• Check settings:

• see leaflet: figure “device view

(7)” as well as parameters 2

and 3

• Check stroke setting at lever.

• seetable2

• SIPART PS2 stops during

“RUN 3”.

• Actuating time too high. • Open reactor completely

and/or set PZ pressure (1) to

maximum permissible value.

• If necessary, use booster.

• SIPART PS2 stops during

“RUN 5”and does not reach

“FINISH” (delay time:

>5min).

• “Batches” (play) in the

positioner -- actuator -- control

valve system

• Part-turn actuator:

Check if set screw of the

coupling wheel is inserted

firmly

• Linear actuator:

Check if lever is connected

firmly to positioning shaft.

• Eliminate any other play

between actuator and control

valve.

Table 5

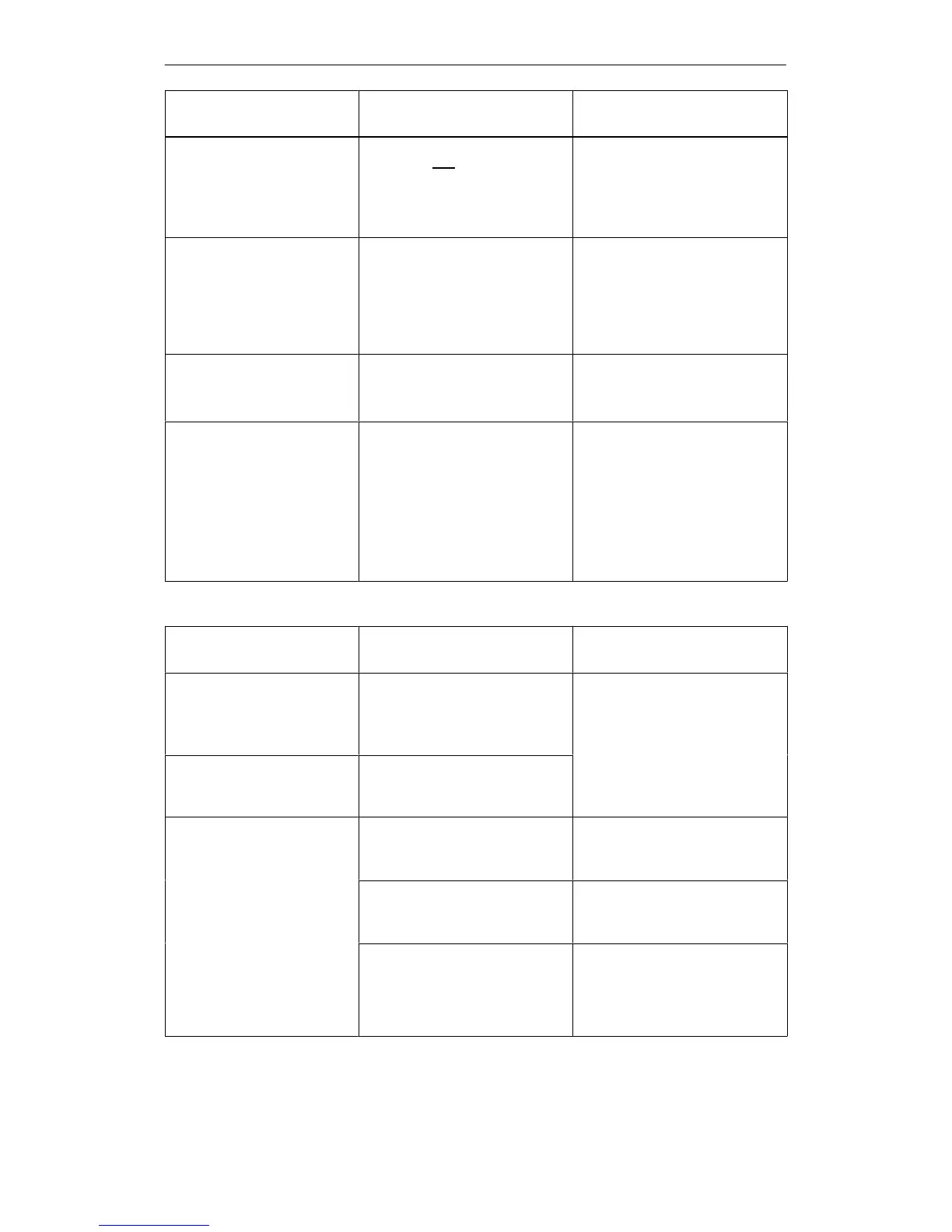

Fault indication

(symptoms)

possible cause(s) Remedies

• For SIPART PS2, “CPU

test” flashes in the display

(approx. every 2 sec).

• Piezo valve(s) do(es) not

switch.

• Water in the pneumatic block

(due to wet compressed air)

• At an early stage, this fault can

be eliminated by subsequent

operation with dry air (if ne-

cessary, in the temperature

cabinet at 50 to 70°C).

• In manual or automatic

mode, the actuator cannot

be moved or only in one

direction.

• Moisture in the pneumatic

block

• Otherwise: Repair

(see chapter 5, page 145)

• Piezo valve(s) do(es) not

switch (no quiet “clicking”

can be heard when the + or

Loading...

Loading...