Operation

139

SIPAR T PS2 Manual

A5E00074631--06

Fault indication

(symptoms)

possible cause(s) Remedies

• Zero point misadjusts

sporadically (> 3 %).

• Stress caused by knocks or

shocks result in acceleration

values that are so high that the

friction clutch is misadjusted

(e.g. with “steam pulses” in

steam lines)

• Eliminate causes of shock

stress.

• Re-initialize positioner.

• Complete device function

failure: also no indication in

the display

• Electrical power supply

insufficient

• Check electrical power supply.

• In the event of continuous high

vibration stress (vibrations):

• Screws on the electrical

connecting terminals can

loosen.

• Electrical connecting terminals

and/or electronic components

can loosen due to vibrations.

• Tighten screws and secure

them with locking varnish.

• Repair (see chapter 5,

page 145)

• For prevention purposes:

Fit SIPART PS 2 on shock

mounts.

Table 9

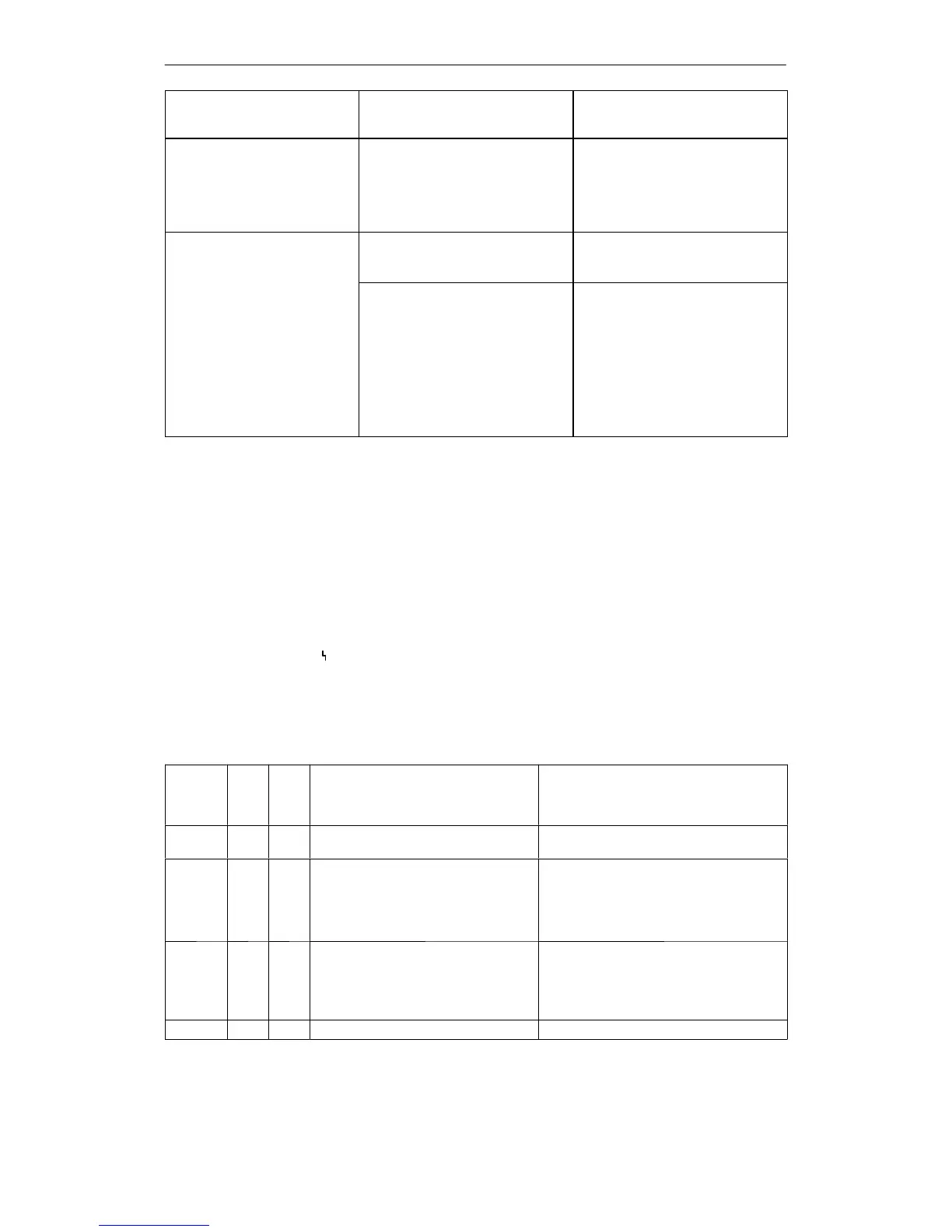

4.6 Meaning of the other display text

Remarks on the tables:

nn stands for variable numerical values

Error symbol

/ (slash): the text segments to the left and right of the-

slash flash alternately

Messages before the installation phase (initial start-up):

Upper

line

Lower

line

Meaning/cause Measure

CPU

START

x

x

Message after applying the electrical

power supply

S Wait

P nnn.n x Potentiometer voltage when

positioner is not initialized (P manual

mode) (actual position value in % of

measuring range)

S Check with the “+” and “--” buttons

whether the entire actuator travel can

be moved along and that “P------”is

never displayed

S Perform initialization

P------ x Measuring range exceeded,

potentiometer is in the inactive zone,

switch transmission ratio selector or

effective lever arm have not been

adapted to the actuator travel

S Switch transmission ratio selector to

90 degrees for part-turn actuators

S Adjust effective lever length for linear

actuators to measuring range

NOINI x Positioner is not initialized S Start initialization

Loading...

Loading...