29 von 37V 07.17

Service Manual BXT3-13/16/19

ENGLISH

Fitting

► Carry out assembly in the reverse order. Ensure for the correct positioning of the teeth between the cam disk

# 44 and tooth segment # 90 on exploded drawing.

► Tighten the cylinder screw # 151 and the cylinder screw #183 with a torque of 1.0 Nm.

► Screw the threaded pin # 86 until it ushes with the base plate.

5.8.2 Disassembly tensioning system BXT3-19

Dismantling

► Loosen the set screw # 85 and remove it from the base plate together with the pressure spring # 83 and pusher

# 84.

► Remove the side cover # 175 by loosening the three cylinder screws # 151 and cylinder screw # 183.

► Lift the rocker lever # 89 on exploded drawing, far enough so that the rocker # 50 can be pulled off to the outsi-

de.

► Remove the tensioning wheel # 46 together with outer ball bearing #18.

► Remove the shafts # 180. Then pull planet gears # 45 sideways out of the ange.

► The remaining ball bearing # 18 as well as the cam disk # 44 can now removed to the outside one by one in this

order.

Fitting

► Carry out assembly in the reverse order. Ensure for the correct positioning of the teeth between the cam disk

# 44 and tooth segment # 90 on exploded drawing.

► Tighten the cylinder screw # 151 and the cylinder screw # 183 with a torque of 1.0 Nm.

► Screw the threaded pin # 86 until it ushes with the base plate.

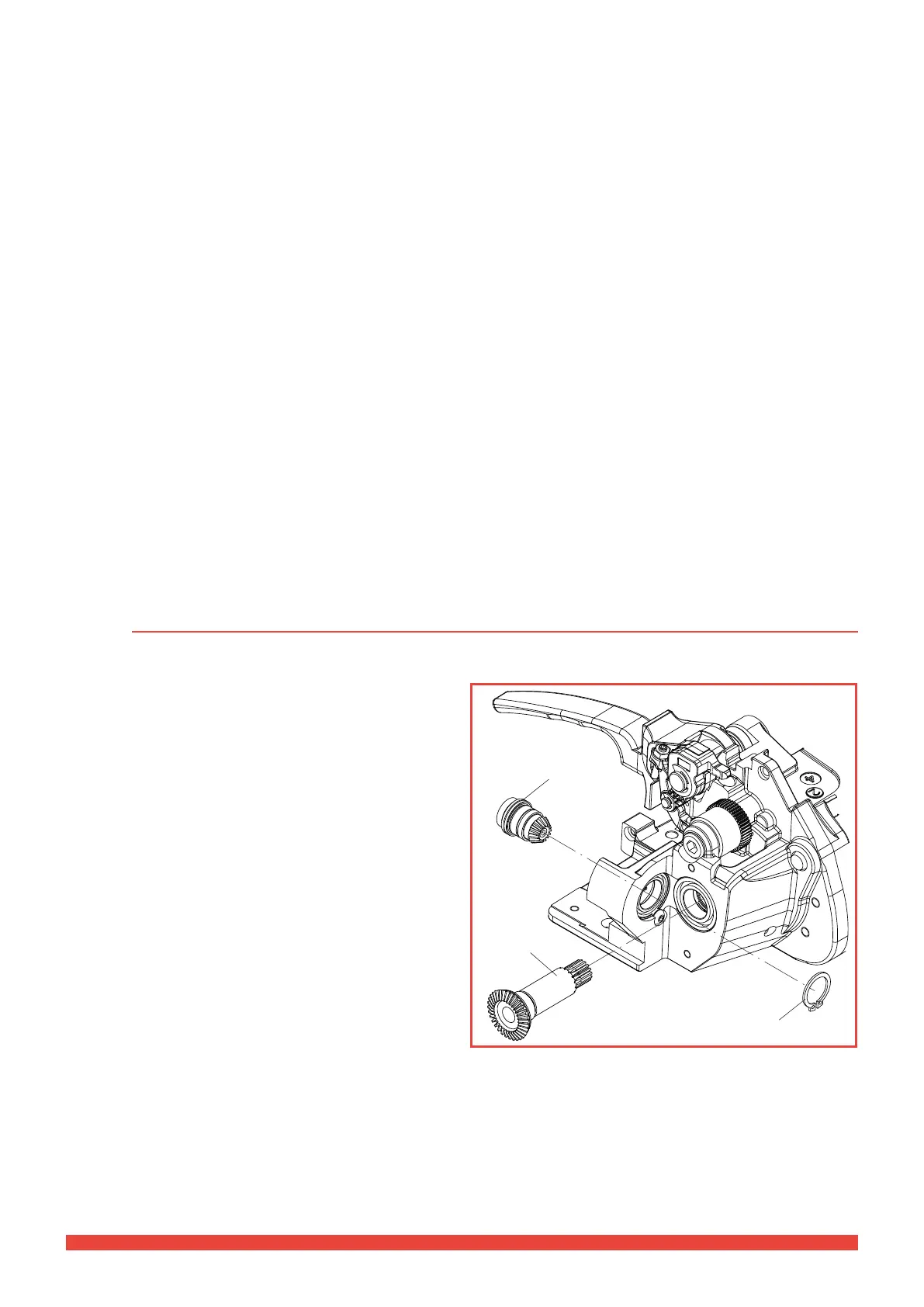

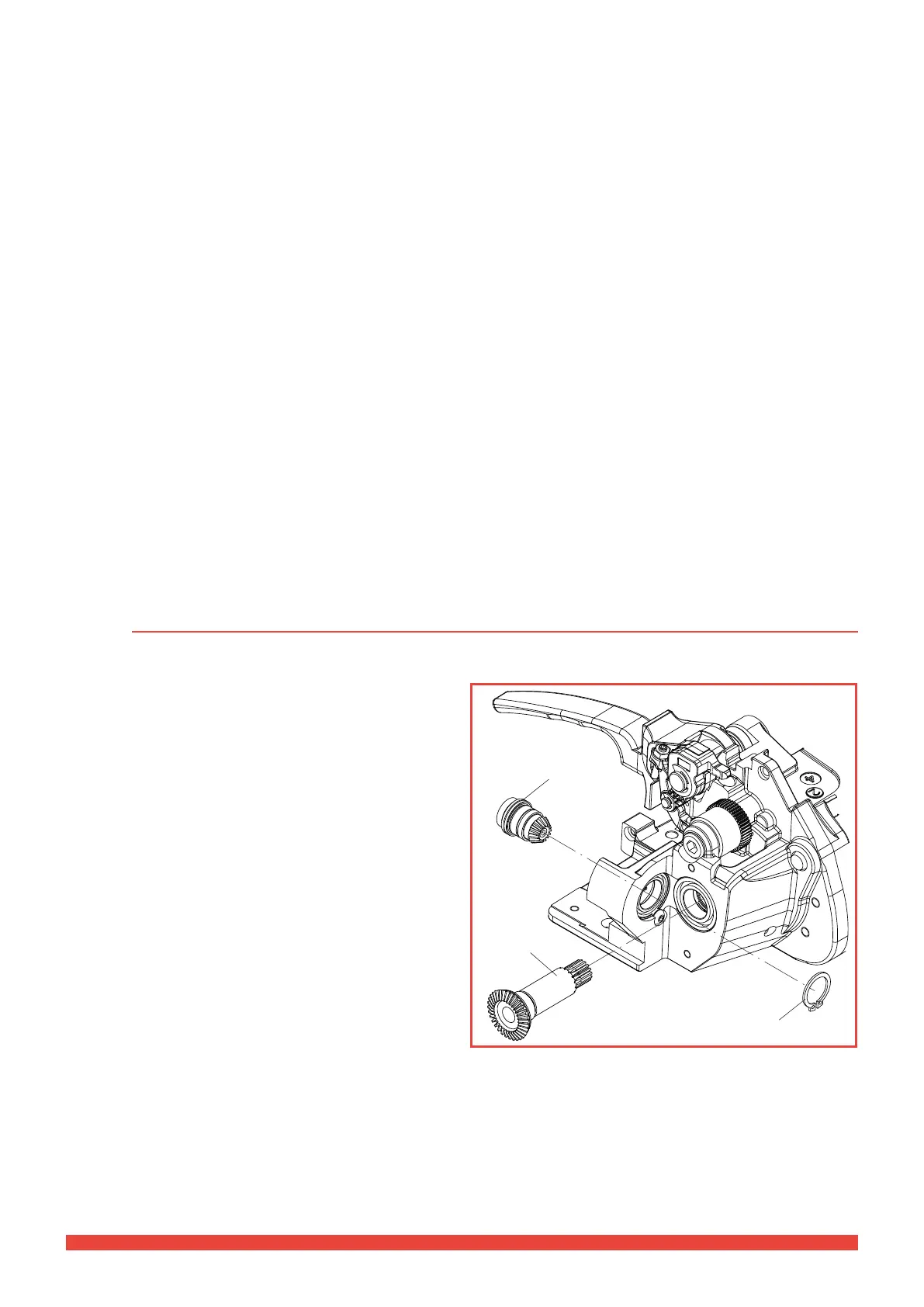

5.9 Gear

5.9.1 Disassembly of the bevel pinion

Dismantling

► Disassemble the welding mechanism from the base

plate (chapter 5.4.1).

► Remove the retaining ring # 136 from the bevel pinion

# 132 and remove the bevel pinion to the rear.

► Pull the bevel wheel with pinion # 12 from the base

plate.

Fitting

► Carry out assembly in the reverse order.

136

132

12

Loading...

Loading...