6 von 37

V 07.17

Service Manual BXT3-13/16/19ENGLISH

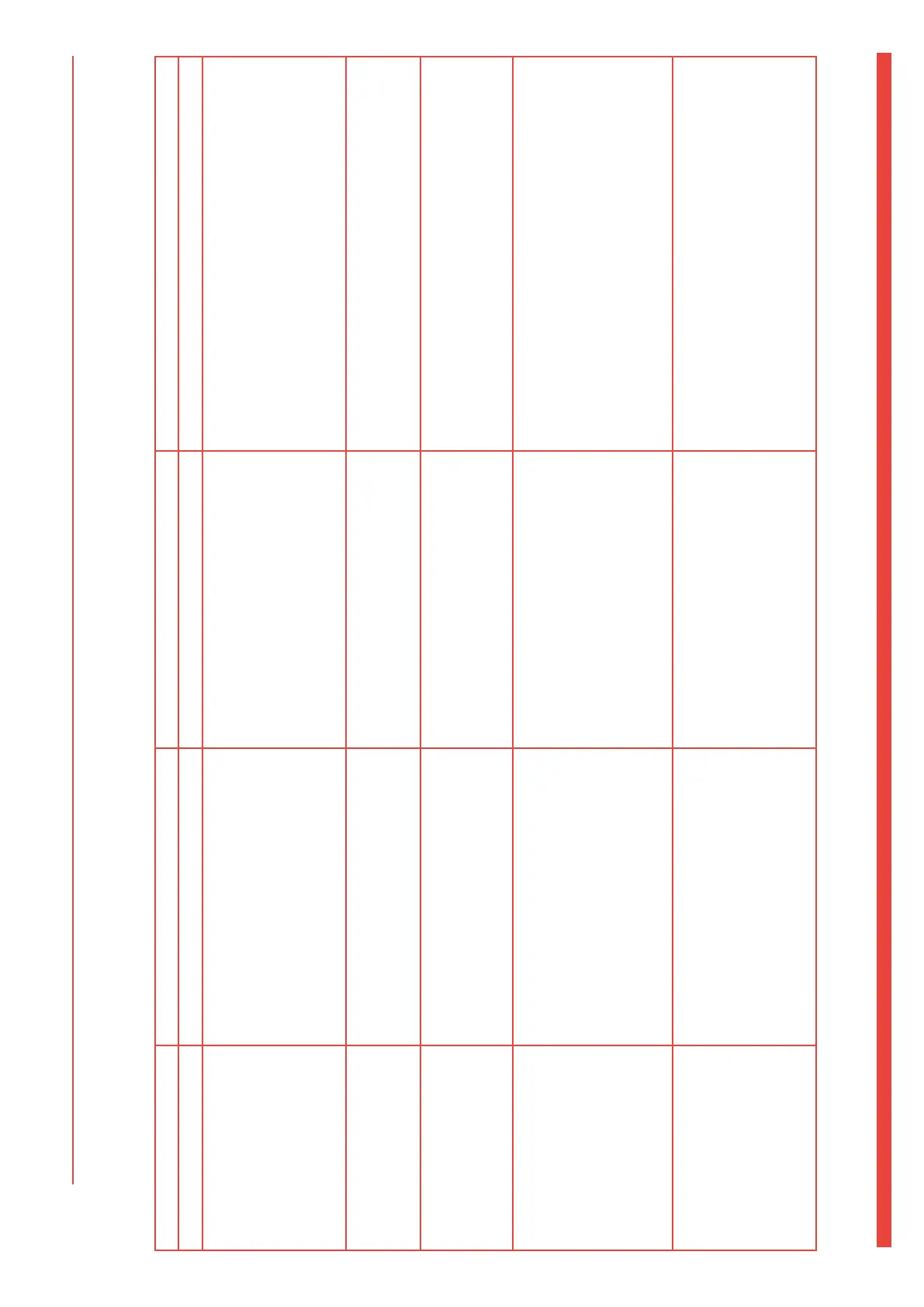

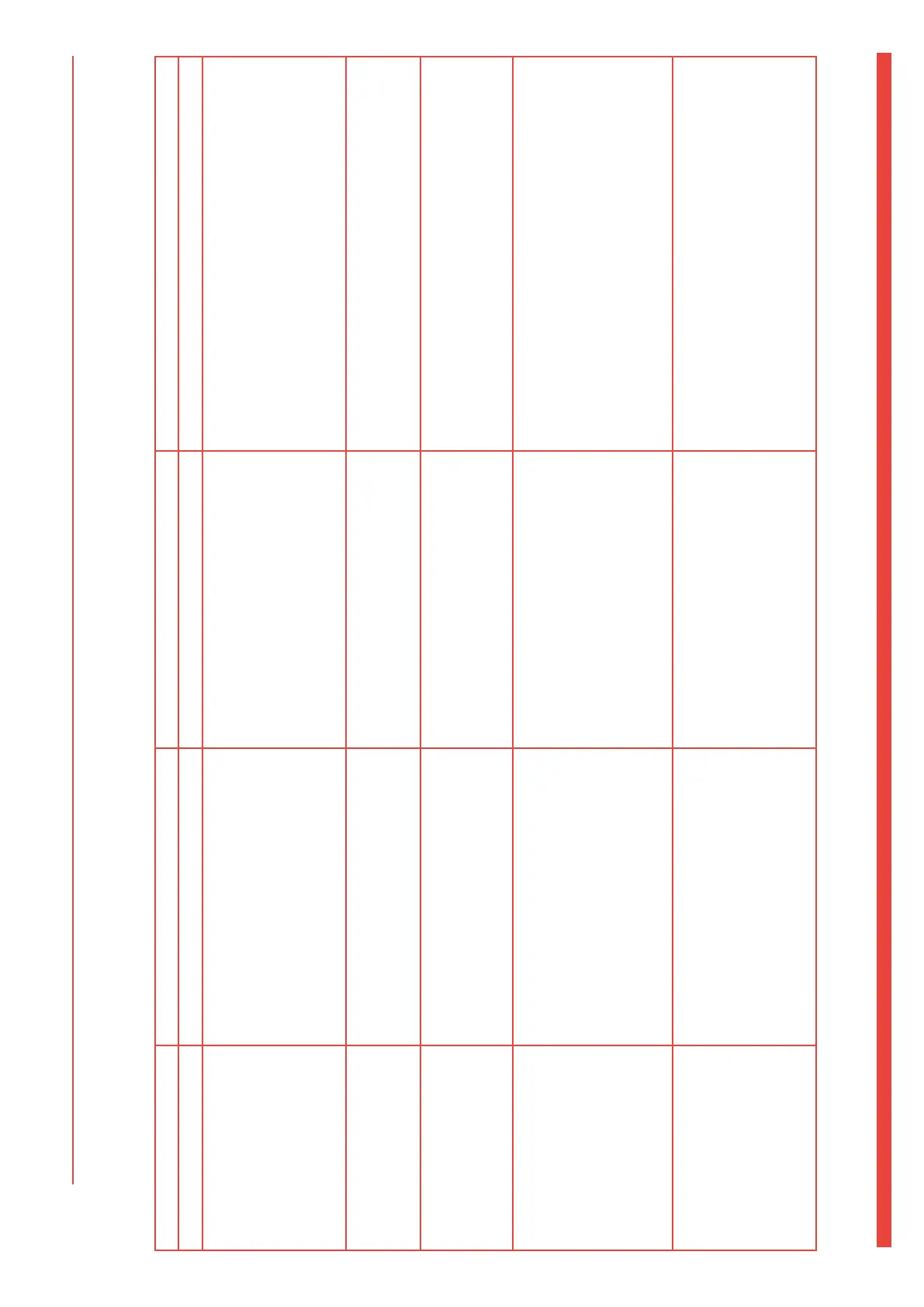

Light applications Average applications Heavy applications

Number of strappings - 1 to 100/day 100 to 500/day > 500/day

Environment – Indoors

– Clean surroundings

– Room temperature

– No contact with uids

– dry

– No abrasive substances present

– No corrosion vapours

– Indoors

– Industrial environment

– Low temperature (<5°C) or strong

uctuation

– Increased humidity

– No abrasive substances present

– No corrosion vapours

– Outdoors, covered

– Industrial environment

– Low temperature (<5°C) or strong uctuation

– Abrasive substances

– High humidity

Typical sectors – General logistics

– Paper industry

– Cardboard box

– Food

– Panel wood

–

– Construction industry (brick production, cement

factories, etc.)

– Sawmills

Recommended

accessories

– If required, hanging bracket – If required, hanging bracket

– If required, second rechargeable

battery.

– If required, hanging bracket

– If required, second rechargeable battery

– If required, optional protection plate set

– If required, optional protection cover set

Special measures: – None – Avoid strong temperature uctuations.

For example, when using in a refrige-

rated warehouse, leave the device in

the cold area, and remove the rechar-

geable battery for charging at ambient

temperatures.

– Avoid strong temperature uctuations. For example,

when using in a refrigerated warehouse, leave the

device in the cold area, and remove the rechargea-

ble battery for charging at ambient temperatures.

– In wet areas, remove the battery from the tool as

soon as it is no longer needed.

– Dry the tool before the next use if it will be exposed

to moisture at the next use.

Maintenance recommen-

dations (see also chapter

2.3)

– Cleaning the tool as required (com-

pressed air).

– Lubricate the welding unit with grea-

se every six months (see operating

instructions, chap. 6.3.)

– Every 2 years, service by a specialist

unit.

– Cleaning the tool as required (com-

pressed air).

– Lubricate the welding unit with grea-

se every six months (see operating

instructions, chap. 6.3.).

– Annual service by specialist unit.

– Cleaning the device as required (Caution! Abrasive

dusts should not be blown into the tool using com-

pressed air).

– Lubricate the welding unit monthly with grease (see

operating instructions, chap. 6.3).

– Six-monthly service by specialist unit.

2.2 Maintenance requirements table

The workload and need for maintenance of the tool may vary strongly depending on the operating environment. The required service work also differs accordingly. The table

below should provide a reference for categorising.

Loading...

Loading...