9 Torque Generator Repair

Reassembly

9 - 8

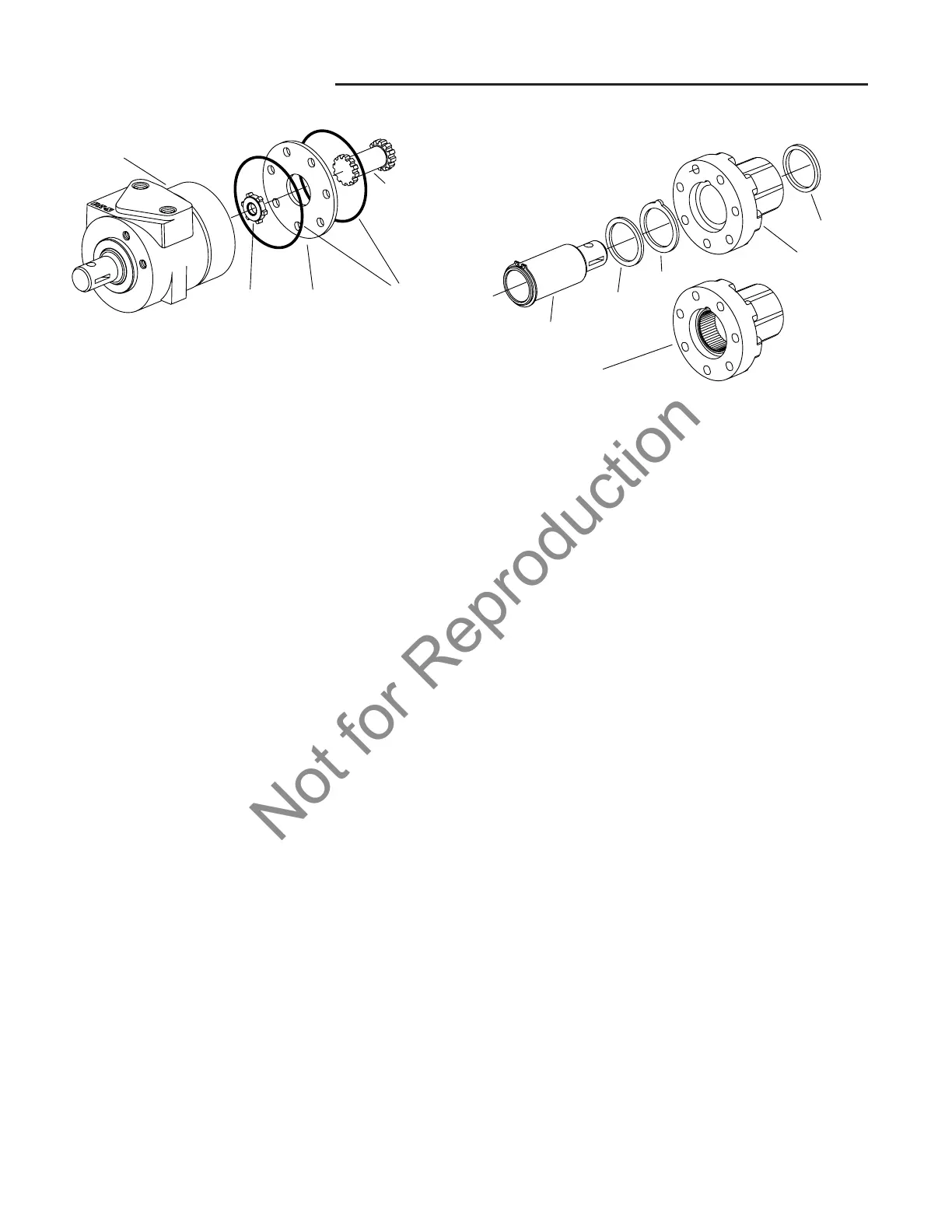

40. Lubricate and install the o-ring into the gerotor or

Gerotor.

NOTE: Spacer is used only with 227 Series (step 41).

41. Install the spacer in the Gerotor star.

42. Lubricate and install the drive into the gerotor or

Gerotor star.

NOTE: The spline on one end of the drive is not as thick

as the other and this thinner spline end must be installed

into the gerotor or Gerotor star.

43. Lubricate and install the spacer plate, with the seal

groove side facing upward. Install by aligning the cap

screw holes with the matching holes in the gerotor or

Gerotor.

44. Lubricate and install the o-ring in the groove located

in the spacer plate.

45. Lubricate and install the quad seal in the groove

located in the power end housing.

46. After installing, make sure the quad seal is not twist-

ed and is firmly seated in its groove.

47. With the quad seal installed, turn the power end

housing over and support it in an upright position

(surface with seven mounting holes up). Lubricate

and install the first washer by aligning the bump on

the washer with the matching recess in the power

end housing.

48. Lubricate and install the second washer in the power

end housing.

NOTE: Careful reassembly will prevent shaft seal dam-

age when pushing the power end shaft into place (step

49).

49. Lubricate and install the power end shaft in the hous-

ing.

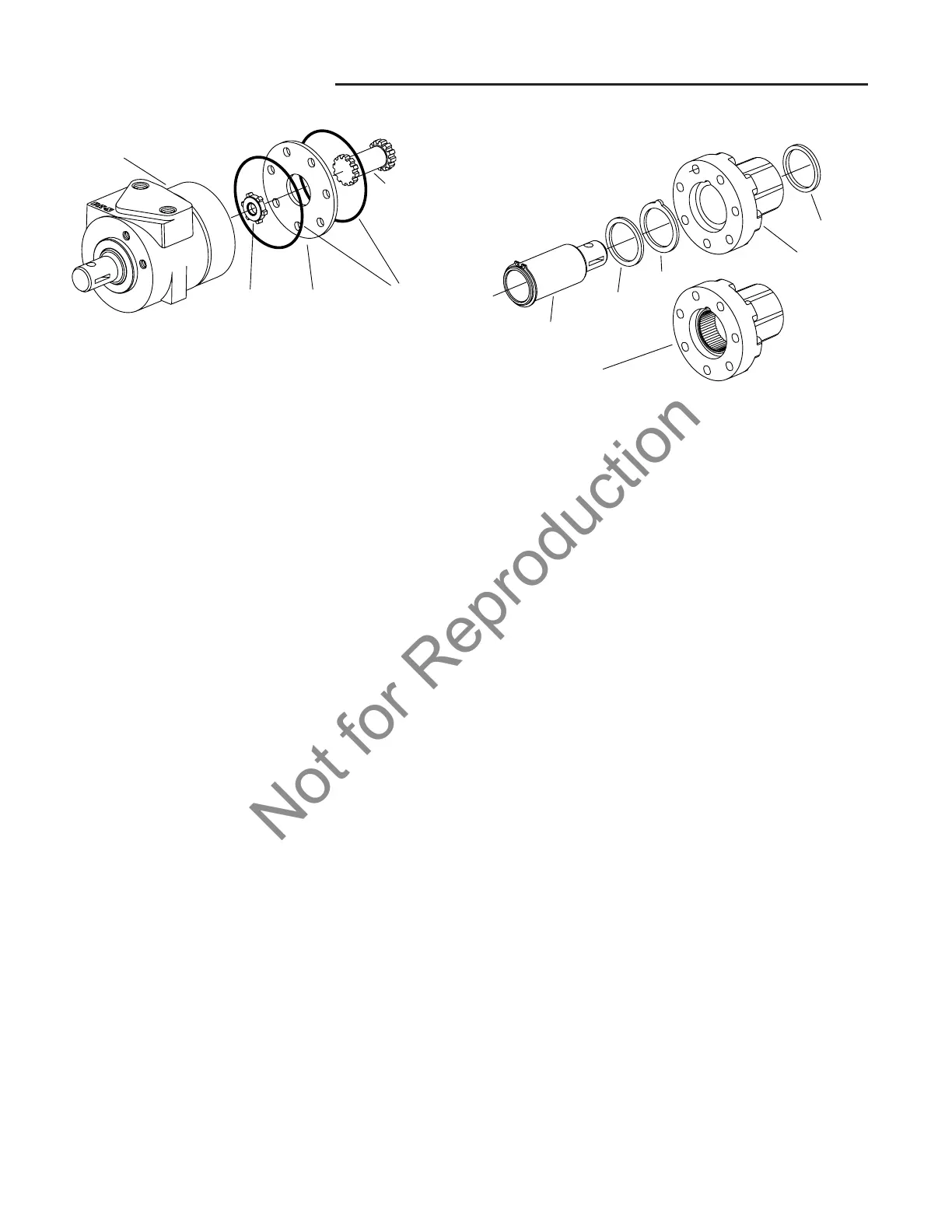

50. Before engaging the power end housing assembly,

align the input and output shaft keyways and cross

holes. Spline on the drive and the spline in the power

end shaft should line up. With the power end assem-

bly installed, rotate housing to align cap screw holes.

51. Install the cap screws and torque in a crisscross

sequence to 23 Nm [200 in-lb].

52. The torque generator is now ready for test and instal-

lation.

Loading...

Loading...