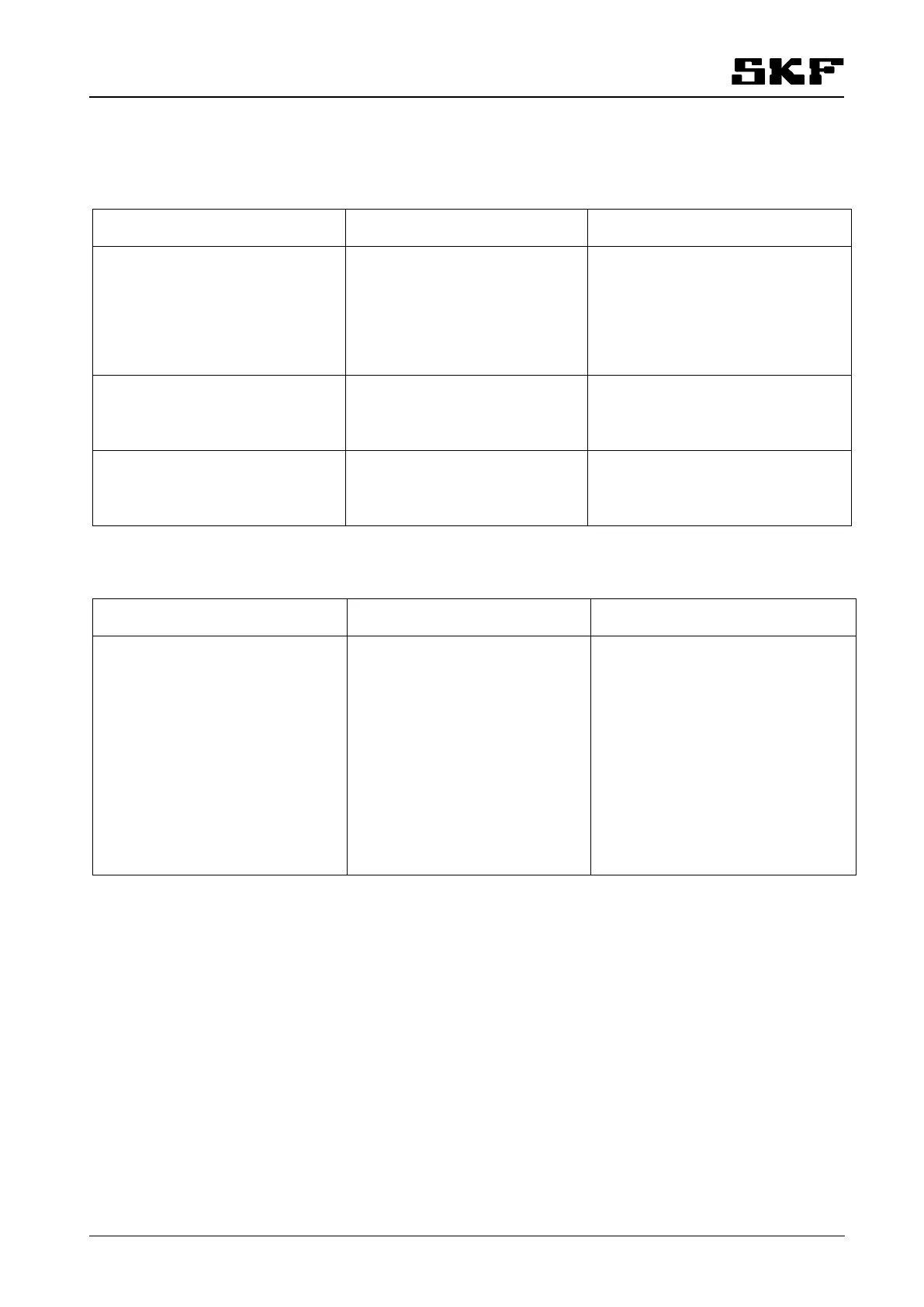

16.2 Troubleshooting table

Table 1: Troubleshooting

Description of malfunction Cause of malfunction Solution

Pressurised air has been cut off.

Insufficient air pressure.

Turn on the air supply and set the

pressure to 2–4.5 bar.

Check that the pressure at the

pressure air regulator is 2–4.5 bar.

Check the air supply hoses for

The pump is activated, but stops

shortly.

Insufficient air pressure.

Check that the pressure at the

pressure air regulator is 2–4.5 bar.

Check the air supply hoses for

A lot of grease leaks from the hole

(11) at the bottom of the cylinder

block (1) (see Figure 2). Small

leaks require no measures.

Contact your Oy SKF Ab repre-

sentative.

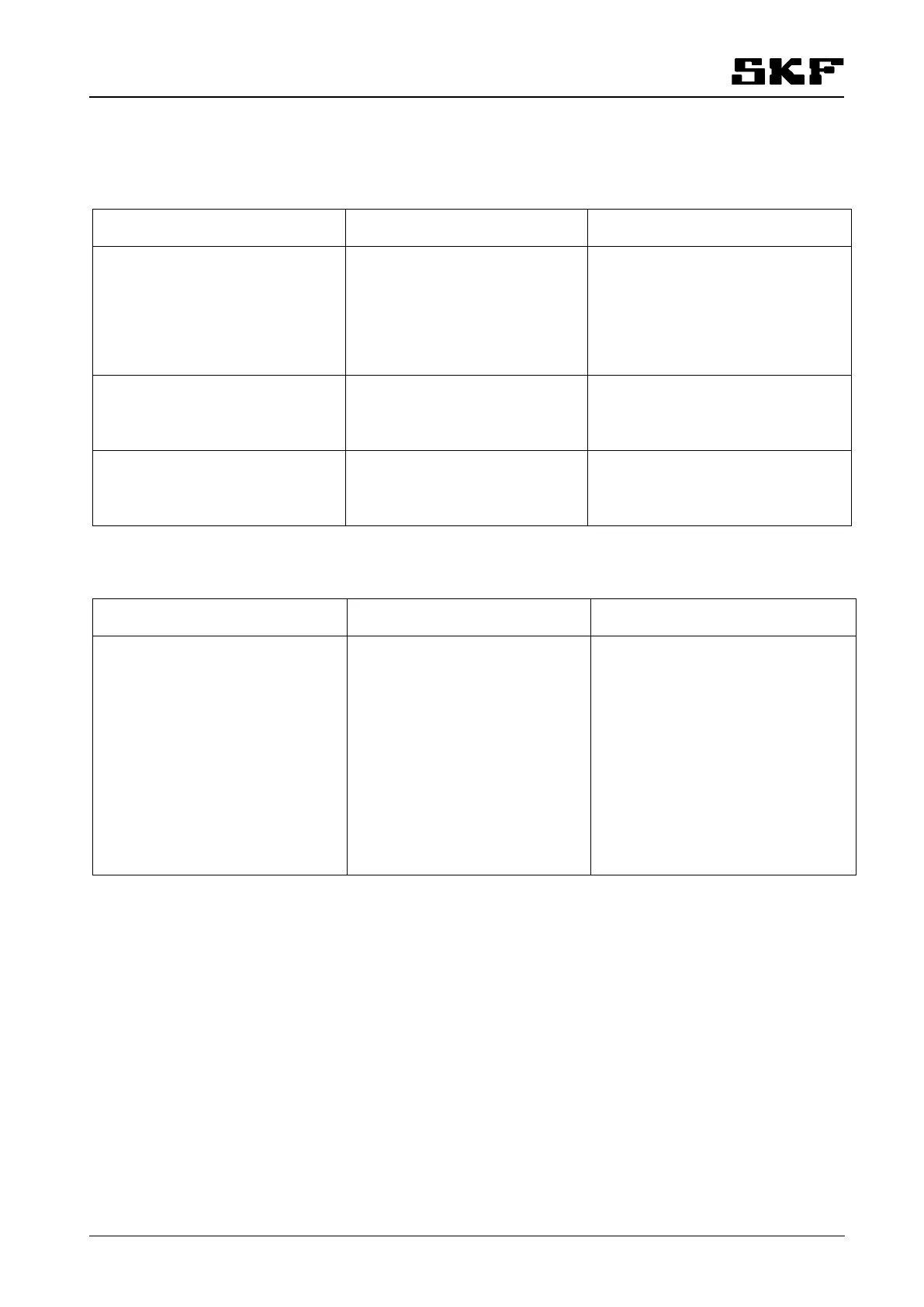

Description of malfunction Cause of malfunction Solution

The pump starts but pressure

does not increase.

The grease filter is clogged.

There is air in the suction piping.

There are impurities in the

pump’s suction inlet.

Lubrication piping leaks.

Clean or replace the grease filter

cartridge.

Bleed the pump of air by opening

the pump’s pressure connection

(P). Check that only grease and no

air comes out of the bleed screw or

the pressure connection.

Contact Oy SKF Ab if necessary.

Check the lubrication piping and

Loading...

Loading...