SJ85AJ 208932AEA

37

Visual & Daily Maintenance Inspections Section 4 – Pre-operation

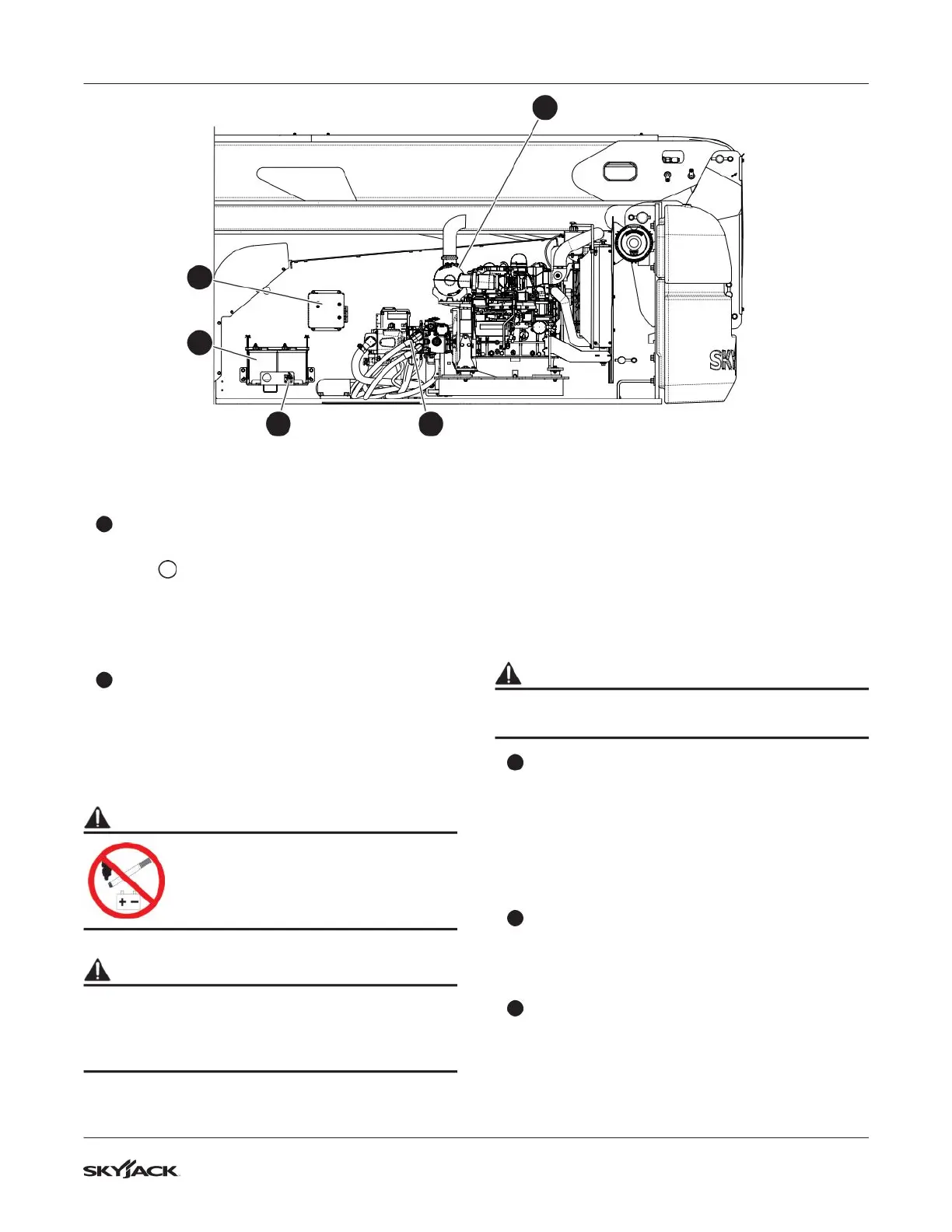

4.2-5 Engine Compartment

Ensure all compartment latches are secure and in

proper working order.

1

Main Power Disconnect Switch

▪

Turn main power disconnect switch to

off position.

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure all cables are secure and switch is in

proper working condition.

2

Batteries

▪

Proper battery condition is essential to good

engine performance and operational safety.

Improper uid levels or damaged cables and

connections can result in engine component

damage and hazardous conditions.

WARNING

Explosion hazard. Keep ames and

sparks away. Do not smoke near

batteries.

WARNING

Battery acid is extremely corrosive - Wear proper

eye and facial protection as well as appropriate

protective clothing. If contact occurs, immediately

ush with cold water and seek medical attention.

1. Check battery case for damage.

2. Clean battery terminals and cable ends

thoroughly with a terminal cleaning tool or

wire brush.

3. Ensure all battery connections are tight.

4. If applicable, check battery uid level. If plates

are not covered by at least 13 mm of solution,

add distilled or demineralized water.

5. Replace battery if damaged or incapable of

holding a lasting charge.

WARNING

Use original or manufacturer-approved parts and

components for the MEWP.

3

Hydraulic Pumps

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure all bolts are properly tightened.

▪

Ensure all ttings and hoses are properly

tightened and there is no evidence of hydraulic

leakage

4

Mufer and Exhaust

▪

Ensure mufer and exhaust system are

properly secured, with no evidence of

damage.

5

Engine Control Console

▪

Ensure there are no loose or missing parts and

there is no visible damage

1

2

5

4

3

Loading...

Loading...