TP301 – Operation, Maintenance and Instructions Manual

2.2

Power Supply

The transmitter is powered with 12 to 45 Vdc using the signal line (2-wire system). The transmitter

quiescent consumption is 3.6 mA; during operation, consumption may be as high as 21 mA, depending

on the measurement and sensor status. If configured for low signal failure, the TP301 shows 3.6 mA

indication if configured for high signal failure, it shows 21 mA indication;,3.8 mA in the case of low

saturation; 20.5 mA in the case of high saturation and measurements proportional to the range position

between 4 mA and 20 mA. 4 mA corresponds to 0% of the working range and 20 mA to100 % of the

range.

Display Controller

Receives data from the CPU and drives the liquid crystal display (LCD).

Local Adjustment

Local adjustment is provided by means of two magnetically actuated switches with no external electric

or mechanical contact, by using a magnetic tool..

Local Indicator

The local indicator is used for signaling and operation in local adjustment. During normal operation, the

TP301 remains in the monitoring mode and the display indicates the valve position, either as a

percentage or as a current readout,according to the end-user configuration. The magnetic tool activates

the local programming mode, by inserting it in orifice Z on the electronic housing.

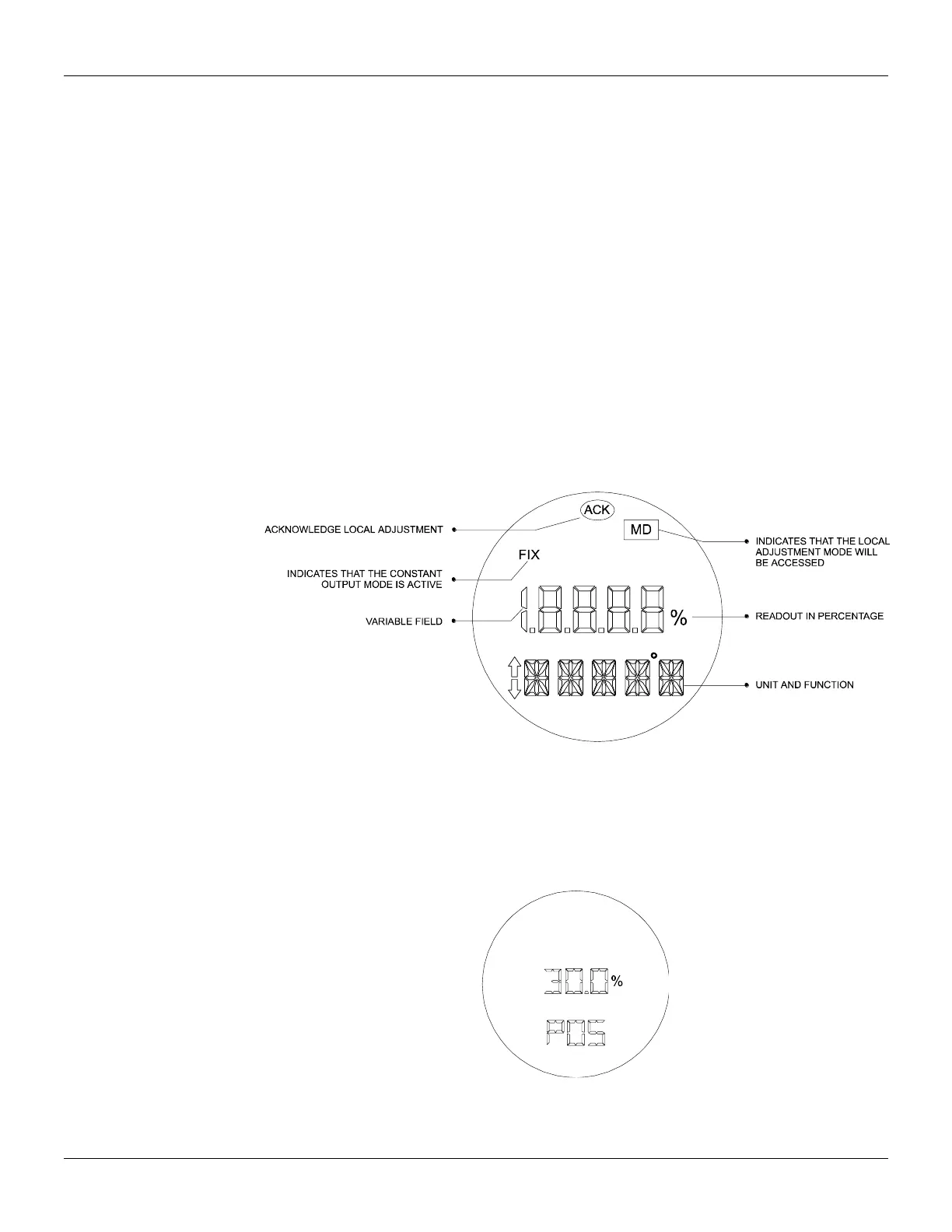

The possible configuration and monitoring operation are shown on figure 2.2. When first powered, the

TP301 initializes, by showing model TP301 and its software version (X.XX) on the display.

Figure 2.2 - Local Indicator

Monitoring

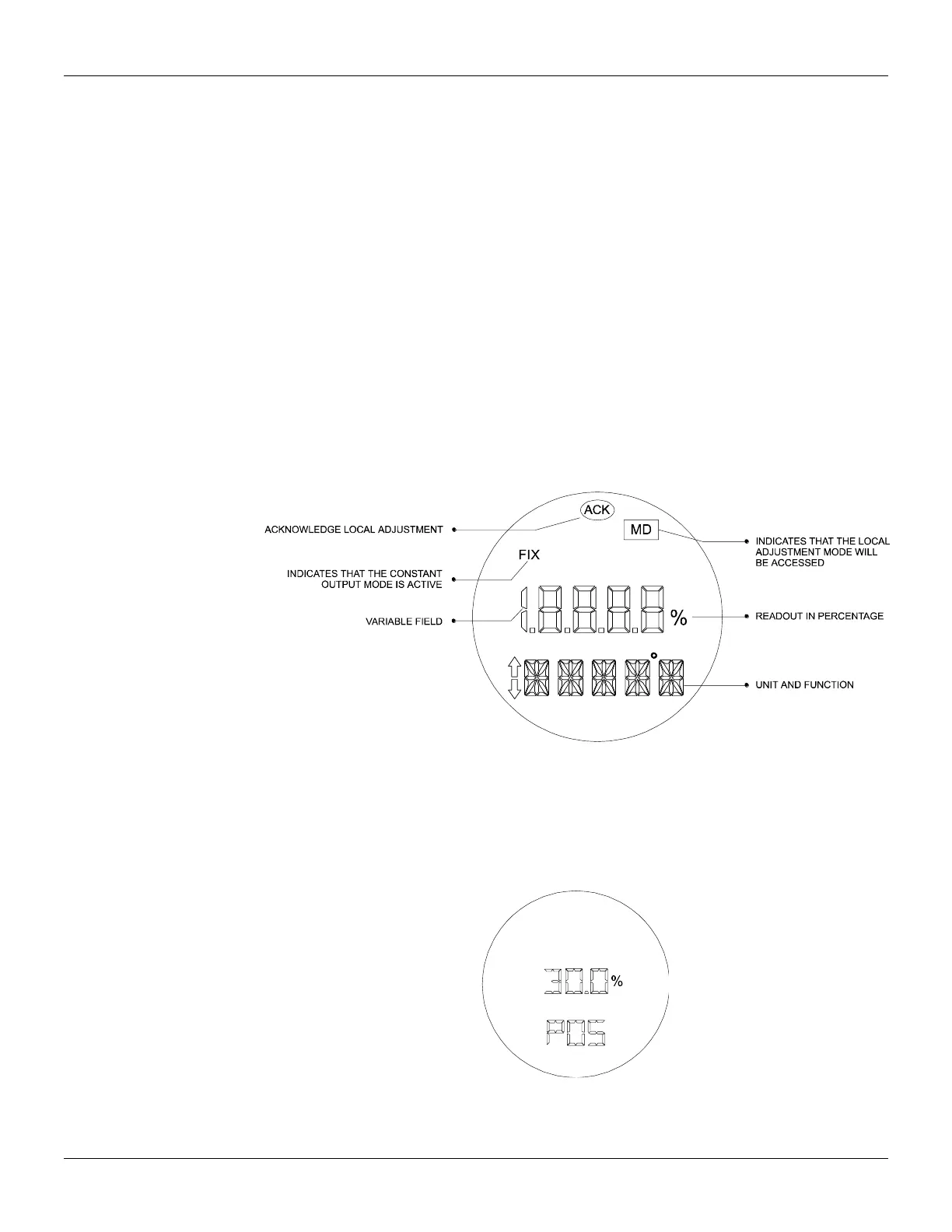

During normal operation, the TP301 remains in the monitoring mode. The figure 2.3 shows the

positioning on the display. The display simultaneously shows the readout and other information chosen.

Normal displaying is interrupted when the magnetic tool is placed in orifice Z (Local Adjustment),

starting the programming and local adjustment mode. The figure 3.1 shows the result of tool insertion in

orifices Z and S, which inform, respectively, movement and actuation of the selected options.

Figure 2.3 – Typical Indicator

Loading...

Loading...