Operation setting: Set lower and upper limit based on actuator

operation position. Operate the same as

manual mode, and P value becomes set value

when it returned to upper directly by mode

button. Ex-factory default values are (431) =

0.0 %, and (432) = 100.0 %. Lower limit

(431) and upper limit (432) can be set only by

conditions below. Unless the condition is

satisfied, check code 2 (CHE0002) is indicated

and upper limit or lower limit are set

automatically. See ”■Check Code List” for

details.

Span to be set : “(432) - (431)” ≧ 60.0 %

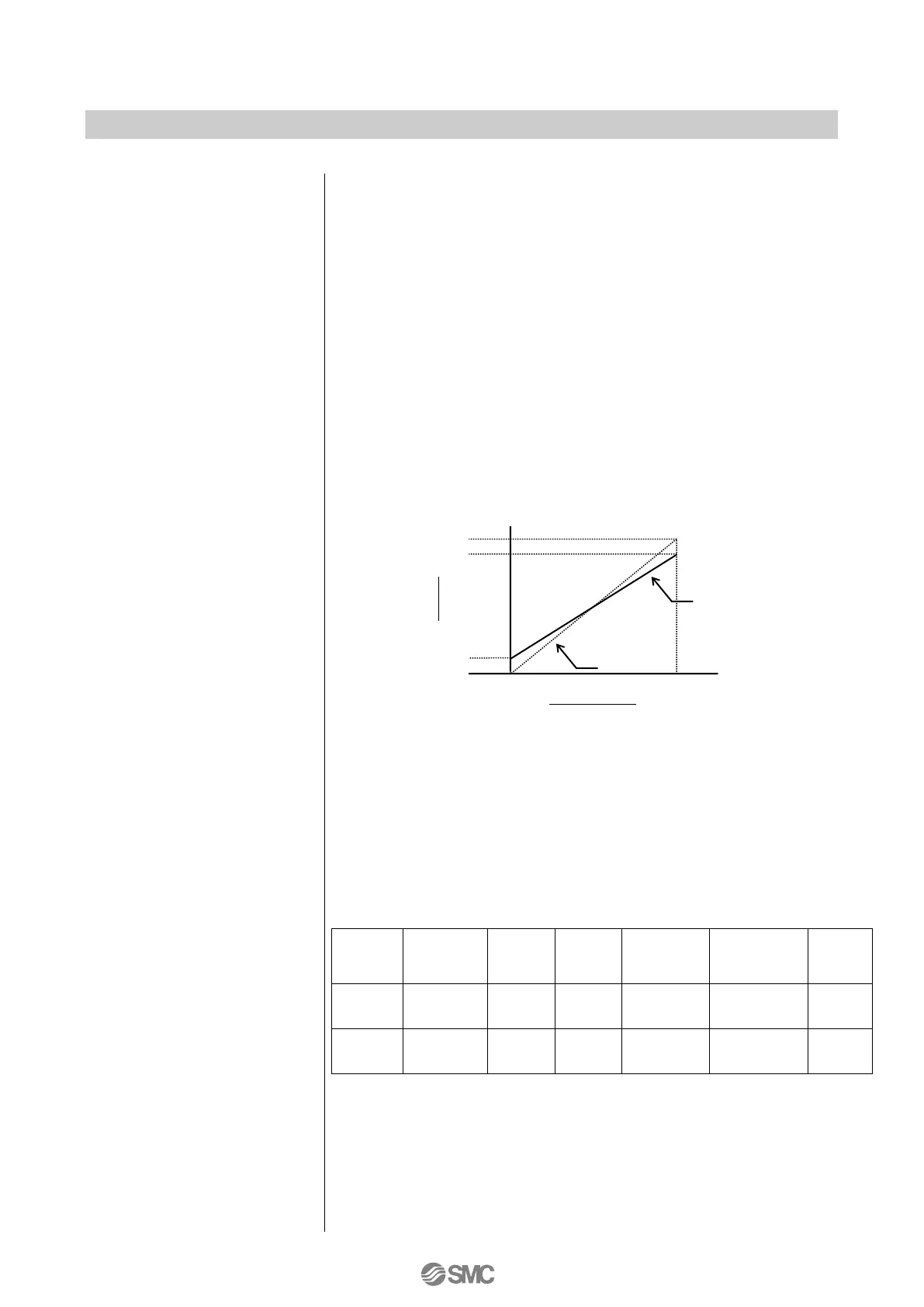

(Ex) Select (200) = dir when

(430) = ACt, (431)=10.0 and (432) = 90.0

When this zero point / span setting is conducted, a position value

(P value) is shown with determination of the set span as 0-100%.

With the settings of (410) = vALu, (411) = 0.0, and (412) = 80.0, it

is reflected to each item as shown on Table 12. Suppose actuator

full stroke is 30mm as an example.

5: When zero / span is set while forced fully-close / fully-open (parameter

code:500) is ON, forced fully-close / fully-open is priotized, and

actuator stroke becomes 30mm.

Loading...

Loading...