74/282

3. Information on the machine

3.5 DATA FOR THE PNEUMATIC INSTALLATION

3.6 FIRST FILM SEALING

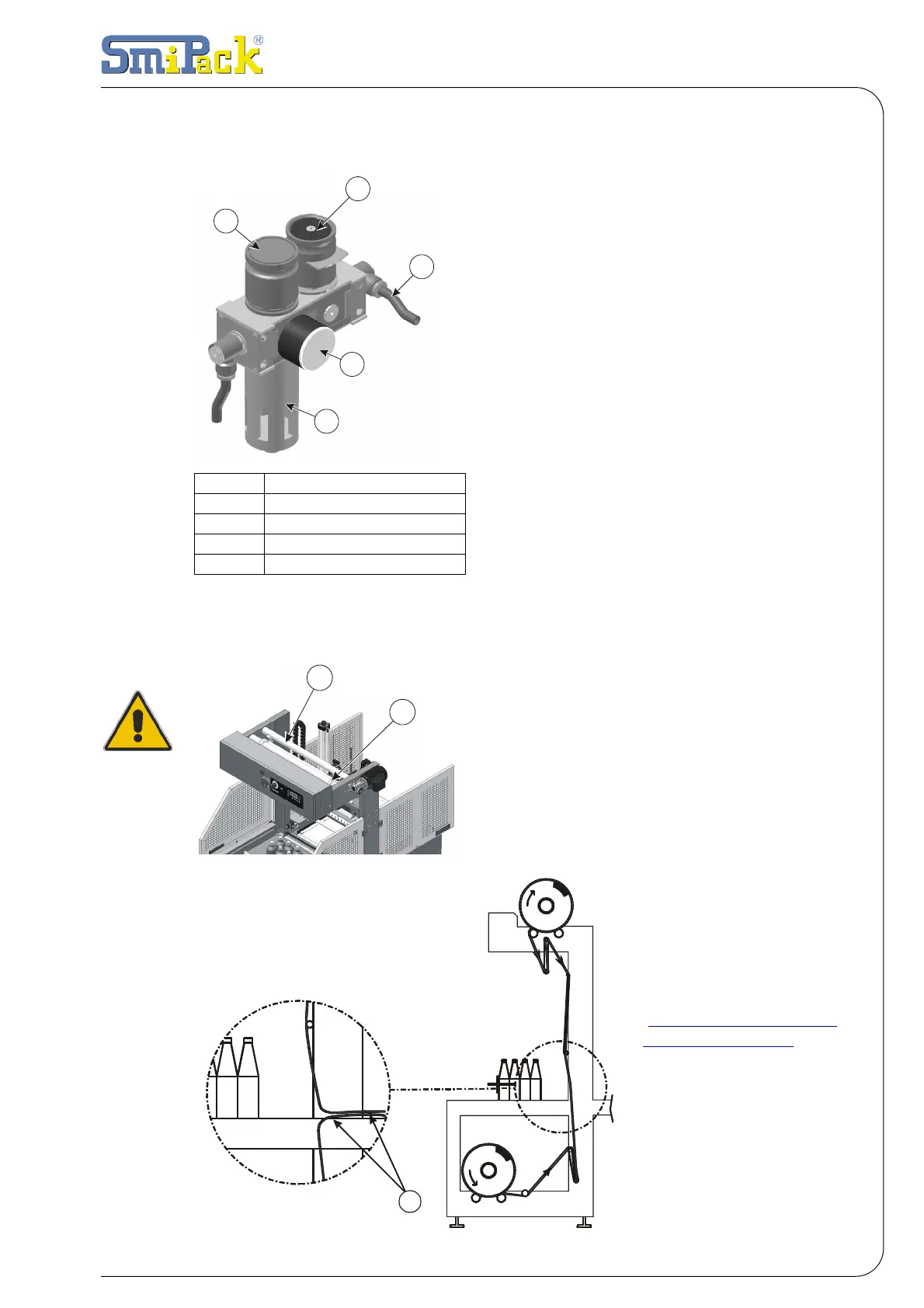

Fig. 3.5.1

The air regulation pneumatic module

composed of a padlock valve and a regulator

filter, with relative pressure gauge used to

regulate the air pressure in the circuit.

Pressing the push button placed above the

regulator 2 , rotate the handle grip so that air

flows inside the plant. Check the air pressure

on the pressure gauge 4.

For the connection, insert the air source into

the entrance link at Ø8 mm.

Compressed aira:

• Working pressure: 5 Bar

• Max. consumption: 16 Normal litres/cycle

• Max. degree of impurity:

solid particles: 40 µm.

liquid particles: 0.5 PPM

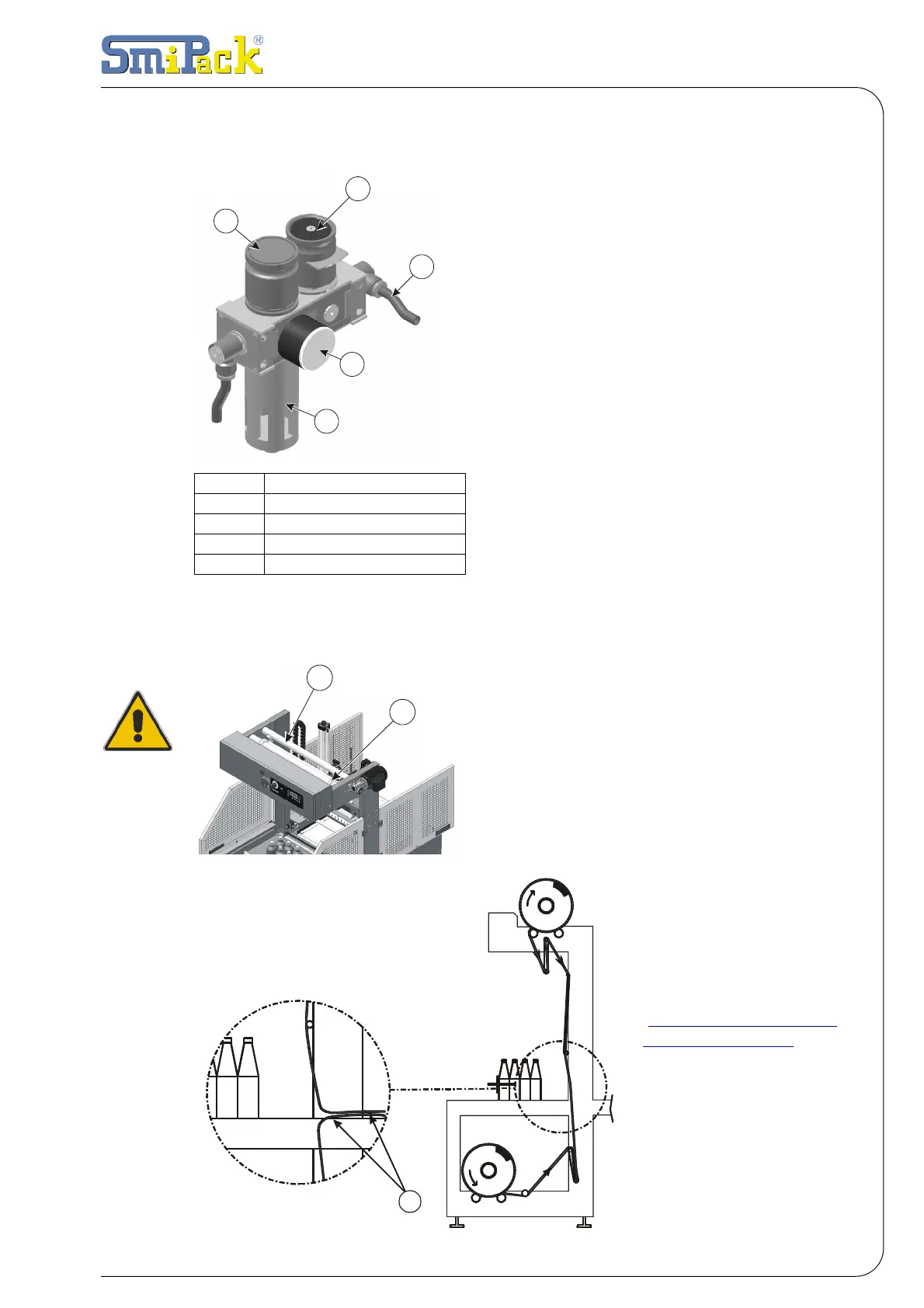

Fig. 3.6.1

The insertion or replacement of the reels must

be performed with the machine switched off.

Center the reels on the relative rollers 1 paying

attention to sharp or pointed surfaces. At this

point move the clamps 2 leaving a few

millimeters between the same and the reel.

Make the film go through

the tensioning bars as in

fig. 3.7.2.

Position and overlap the

two edges of the film 3

over the sealing bar.

Close the safety door and

switch on the machine

and start the first sealing,

(

See par "MANUAL

SELECTION" pag. 76. ) and

then remove wastage.

2

3

4

5

1

1

Padlock valve

2

Regulator

3

Ø8 Power supply

4

Pressure gauge

5

Filter

3

1

2

Fig. 3.6.2

Loading...

Loading...