Copyright 12/14 46 S/N XXXX WO#XXXXXX

Smoracy, LLC

MODEL 3680 MAINTENANCE

MAINTENANCE SECTION

Your recycler will give you many hours of production time with inexpensive repairs if you follow the

proper maintenance instructions in this manual. A Daily Maintenance Check must be done each day prior to

putting your Recycler to work. Maintenance shall be performed only by those authorized by the owner and

trained to perform such operations. The authorized person shall notify the crew that maintenance is to be done

and that the Recycler must be shut down and secured.

It is the responsibility of the owner or employer to provide education and training in job-site specific hazards

associated with the job, work procedures and practices involved, special precautions and personal protective

clothing and equipment requirements as applicable to employee job assignments.

Before staring any maintenance on the recycler, any person involved MUST read and understand all safety

precautions described in this manual. Failure to do this may cause serious injury and even death!

DO NOT work on the Recycler if the engine is running. A clutch can self-engage if either the pilot or throw-out

bearing happens to seize to the main output shaft. Make sure that you are wearing all of your personal

protective equipment and you have the key to the Recycler in YOUR pocket. It is your responsibility to ensure

that the Recycler is isolated and will not operate before proceeding with any maintenance or repairs. When all

safety procedures are in place you may start working on the machine.

Any repairs that require welding or the use of a cutting torch should be done in the morning so that a smoldering

fire will be caught during the day. You should always keep several fully charged fire extinguishers with the

machine at all times. Before welding any place on the machine it is imperative that you follow the specific

engine manufactures instructions for proper welding and grounding procedures. An electrical spike from the

welder will fry the ECU (Electronic Control Unit), which is the computer that controls your engine and is very

costly to replace. The ECU must be disconnected and the Battery Disconnect Switch turned off.

Some maintenance requires that you work under the Feedwheel while it is in the raised position. The

Feedwheel Yoke assembly is equipped with two safety devices that must be put in place before work

commences.

With the engine running, clutch disengaged, and the Cutterhead completely stopped, raise the Feedwheel Yoke

to its maximum height. Then extend or engage the Yoke Lock Bars located on top of the Cutterhead housing. Now

use the Safety Chain attached to the Discharge Belt Conveyor rest and secure it to the lug located on the right side

of the Feedwheel Yoke. With the safety devices in place lower the Feedwheel Yoke until it contacts the Yoke Lock

Bars and the Safety Chain pulls tight. Finally do not attempt any type of maintenance without first disengaging

clutch, turning off engine, waiting for the Cutterhead to come to a complete stop, turning Battery Disconnect Switch

off, and you must have the ignition key in YOUR possession.

For added safety it is a good practice to use an additional log chain to help support the Feedwheel Yoke to the

conveyor rest. When all safety devices are in place you may start maintenance to the machine.

WARNING

WARNING

DANGER

DANGER

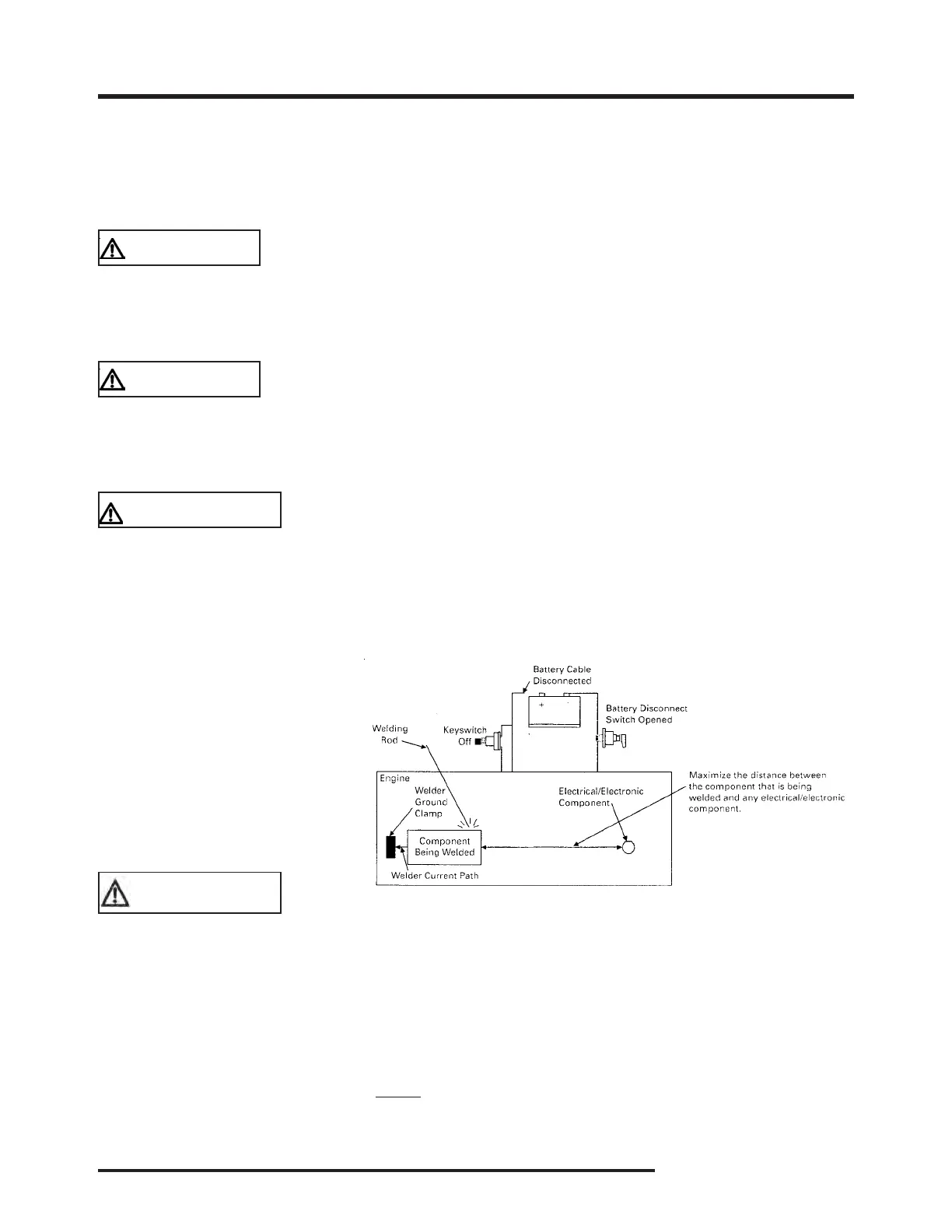

Example from Caterpillar engine manual: Welding on Engine Guideline Diagram

The current flow from the welder to

the welder ground will not cause

damage to any of the associated

components.

Loading...

Loading...