20

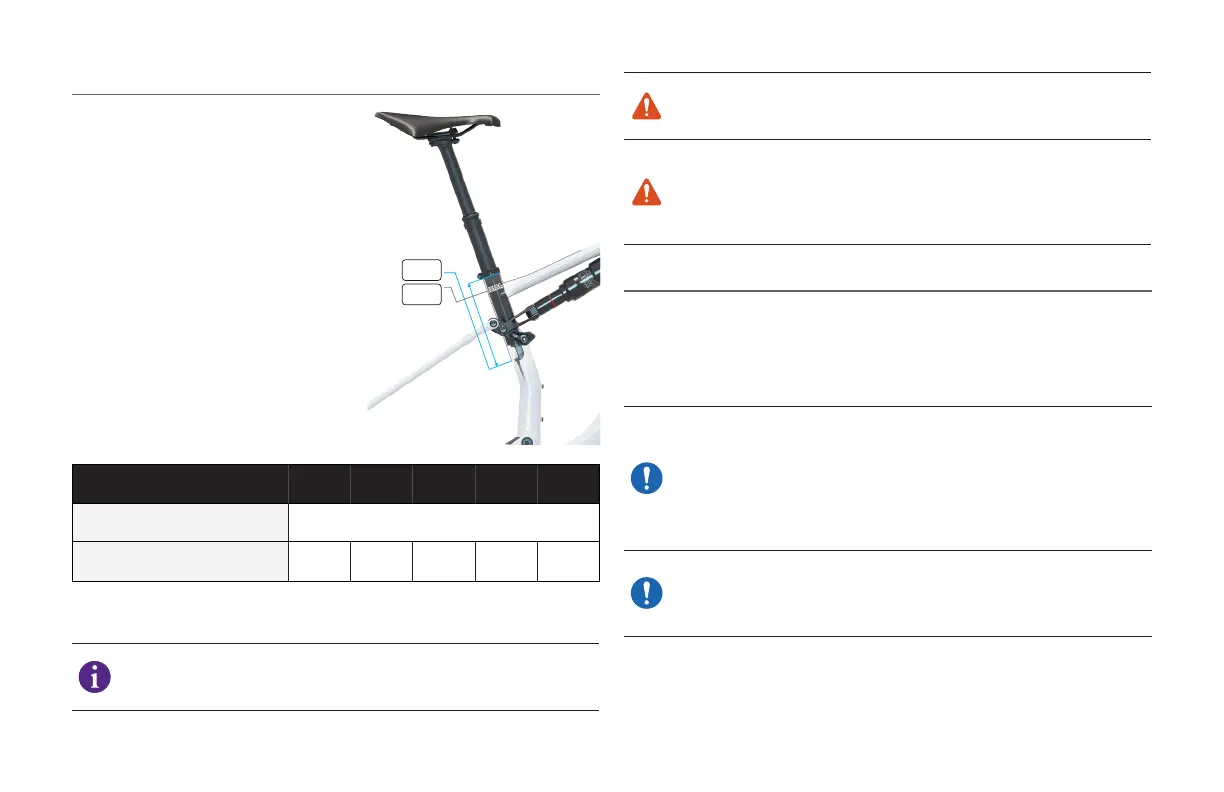

5.2. SEATPOST MINIMUM / MAXIMUM INSERTION

Both the frame and seatpost have

minimum insertion requirements. In

addition, the frame has a maximum

insertion requirement to prevent damage

to the frame and seatpost.

Minimum insertion:

The seatpost must be inserted into the

frame deep enough so the minimum

insertion/maximum extension (min/

max) mark (B) on the seatpost is not

visible. The frame requires a minimum

of 80 mm of insertion.

Maximum insertion:

The seat tube is reamed to a specified

maximum insertion depth (A) for each

frame size. This ream depth limits the

insertion depth of the seatpost.

FRAME

XS S M L XL

Minimum insertion (mm) 80

Maximum insertion (mm) 220 220 244 285 330

Once the saddle height is determined, using a torque wrench and 4 mm

hex bit, torque the supplied seatpost clamp bolt to 6.2 Nm / 55 in-lbf.

If the desired seat height cannot be achieved within the minimum

and maximum insertion requirements, the seatpost should be

replaced with a shorter or longer one.

A

B

WARNING! Failure to follow the seatpost insertion requirements

may result in damage to the frame and/or seatpost, which could

cause you to lose control and fall.

WARNING! For general instructions regarding the installation

of the seatpost, refer to the appropriate section in the Owner’s

Manual. Riding with an improperly tightened seatpost can allow

the saddle and seatpost to slide down, which can damage the

frame and cause you to lose control and fall.

5.3. BOTTOM BRACKET

All models have a threaded 73 mm width bottom bracket shell and are

compatible with any BSA threaded outboard bearing bottom bracket.

Please refer to the crank manufacturer documentation for bottom bracket

compatibility. Before installing the bottom bracket and crank, make sure

all housings and wires are routed through the frame.

CAUTION:

Do not face the bottom bracket shell! This can prevent

proper installation of the crank. Your Specialized frame does not

require any bottom bracket shell pre-installation preparation, as

all surfaces have been precisely machined to specific tolerances at

the factory for proper interface with a compatible crankset. Please

refer to the manufacturer's instructions for crank and bottom

bracket installation.

CAUTION: Always use a bottom bracket equipped with a sleeve

between the two cups. Running a bottom bracket without the

sleeve can result in housings and/or wires contacting the crank

spindle, which can result in wear.

Loading...

Loading...