Thermo E 200 / 320 2 Technical Data

201

2 Technical Data

Unless limiting values are defined, the technical data

should be understood with tolerances of ±10% common

for heaters at an ambient temperature of +20°C and at

nominal voltage.

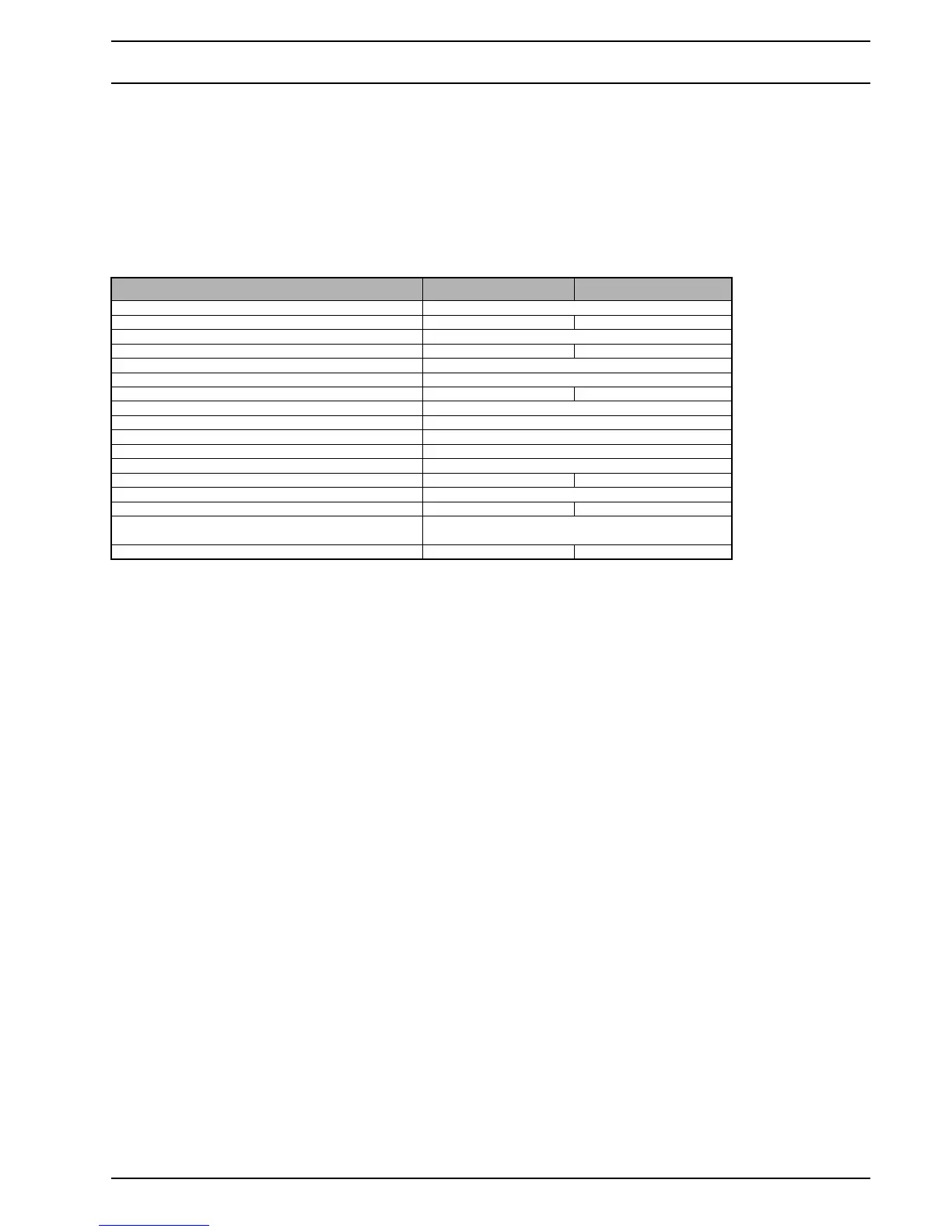

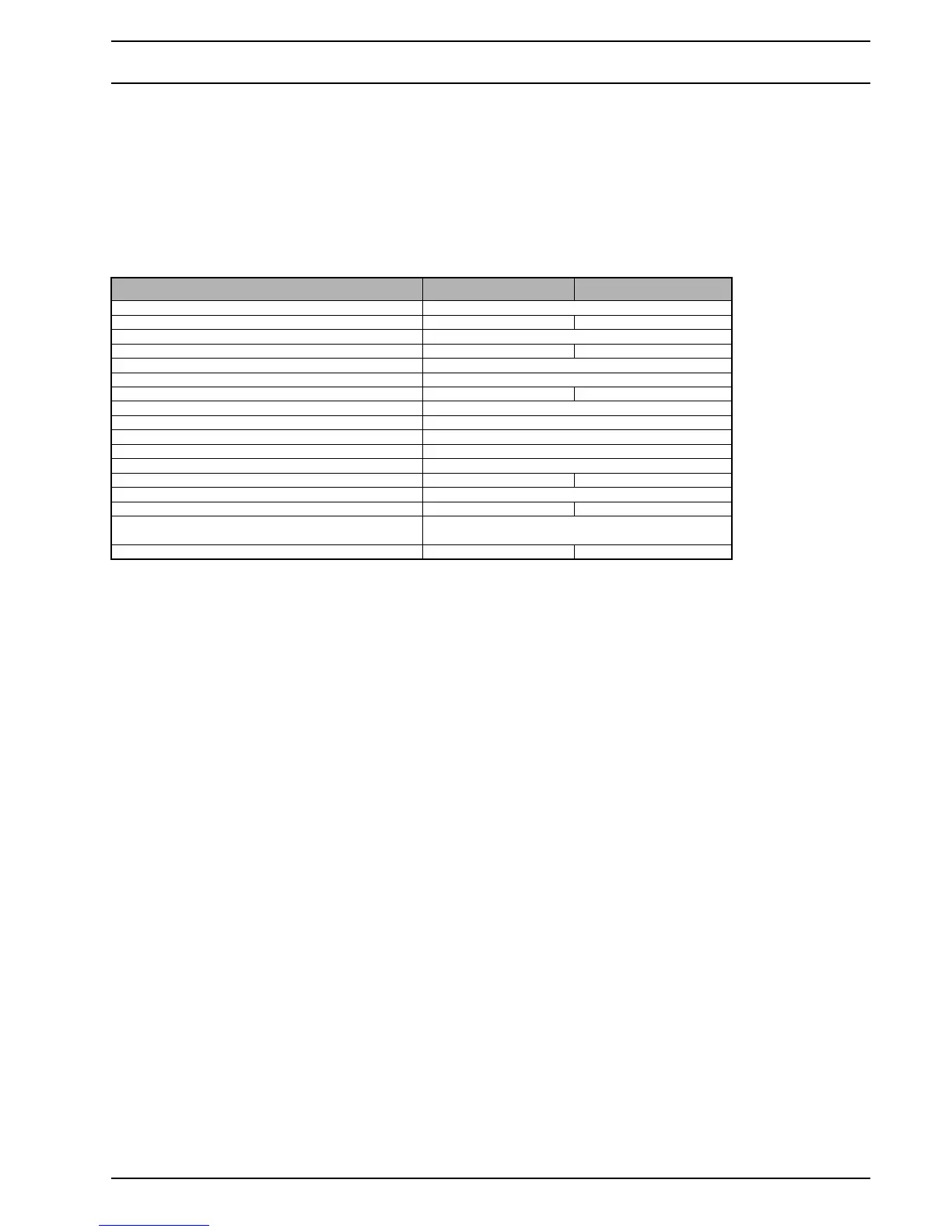

Table 201 Technical Data

2.1 Electrical components

All heater components as well as the circulating pump and

the timer are designed for 24V nominal voltage. The

temperature sensor voltage is regulated by the control

unit.

NOTE

Circulating pumps must be assigned to the heaters

according to the flow resistance in the coolant circu-

lation system.

2.2 Fuel

Only fuels listed on the type plate as well as fuels

approved by Spheros may be used. The fuel use limita-

tions in the heater listed below must be observed.

– Diesel fuel according to DIN EN 590 and DIN 51628:

The limitations of use of the standard apply, hence

winter diesel down to -20°C, Arctic diesel down

to -40°C

– Light fuel oil according to DIN 51603 (above 0°C)

– Mixture of 70 Vol-% diesel fuel (winter diesel) accord-

ing to DIN EN 590 or DIN 51628 and 30 Vol-% Bio-

diesel according to DIN EN 14214: -5 .. -10 °C without

preheating system, -15°C with nozzle block preheater

and heated fuel filter (use limitations depending on

fuel quality).

At temperatures below 0°C commercially available winter

diesel should be used. This especially applies for fuel

extraction from a separate fuel tank.The use of lubrication

and flow improving additives is permitted. No negative

impact is known at time of the preparation of this work-

shop manual.

ATTENTION

The listed temperature ranges, hence minimum per-

missible temperatures strongly depend on the re-

spective fuel quality. In case of bad-quality fuel the

use limitations may deviate, e.g. in case of too high

water content.

When fuels are used, their respective limitations of

use must be observed and appropriate measures

(nozzle block preheater, electrically heated filter)

must be applied as needed.

In case fuel is extracted from the vehicle tank, the

vehicle manufacturer's mixing regulations shall

apply.

Heater Thermo E 200 Thermo E 320

Design High-pressure atomizer

Heat flow rate kW 20 32

Fuel Diesel / light fuel oil

Fuel consumption kg/h / l/h 2.0 / 2.7 3.2 / 4.1

Nominal voltage V (DC) 24

Operating voltage range V (DC) 20.5...30.0

Electrical power consumption at 24 V * W 55 100

Combustion air intake temperature °C -40...+ 85

Ambient temperature during operation °C -40...+ 85

Storage temperature °C -40...+ 90

Operating overpressure bar max. 2.0

Heat exchanger filling volume l 1.8

Minimum water flow ± …l/h 2400 ± 200 2700 ± 200

Minimum coolant circulation volume l min. 25.0

CO

2

in exhaust at nominal voltage Vol % 9.5 ± 0.5 10.0 ± 0.5

Heater dimensions

(tolerance ± 3 mm)

mm Length 593 / Width 247 / Height 224

Weight kg 16.5 17.3

* without circulating pump

Max. continuous current of the circulating pump 8.75 A, max. peak current for 0.5 s duration = 90 A - We recommend the use of Spheros

circulation pumps for highest efficiency and reliability! In order to reduce starting currents the circulating pump can be synchronized by the

control unit for a short time period during activation.

Confirm compatibility in case pumps provided by different manufacturers are used!

Loading...

Loading...