5 Troubleshooting and error correction Thermo E 200 / 320

512

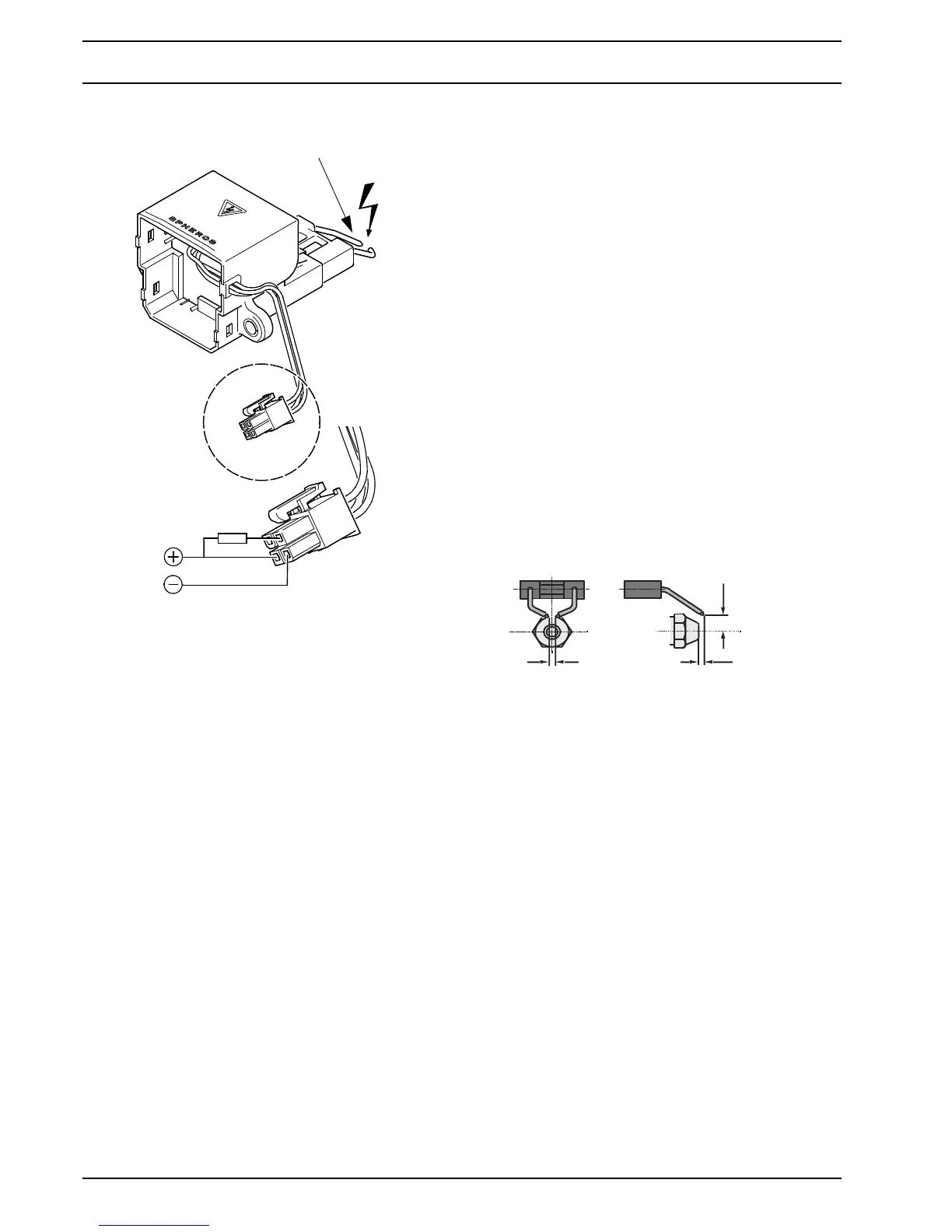

Manual functional test when disassembled

• Remove electronic ignition unit (see 8.6).

• Connect ignition electrode.

• Apply 24V direct voltage according to Fig. 505.

• Nominal condition: Ignition sparks the ignition elec-

trode jump over with a rate of 6Hz.

• After the test is completed, install the electronic igni-

tion unit (see 8.6) and attach the ignition electrode.

• Install burner (see 8.2).

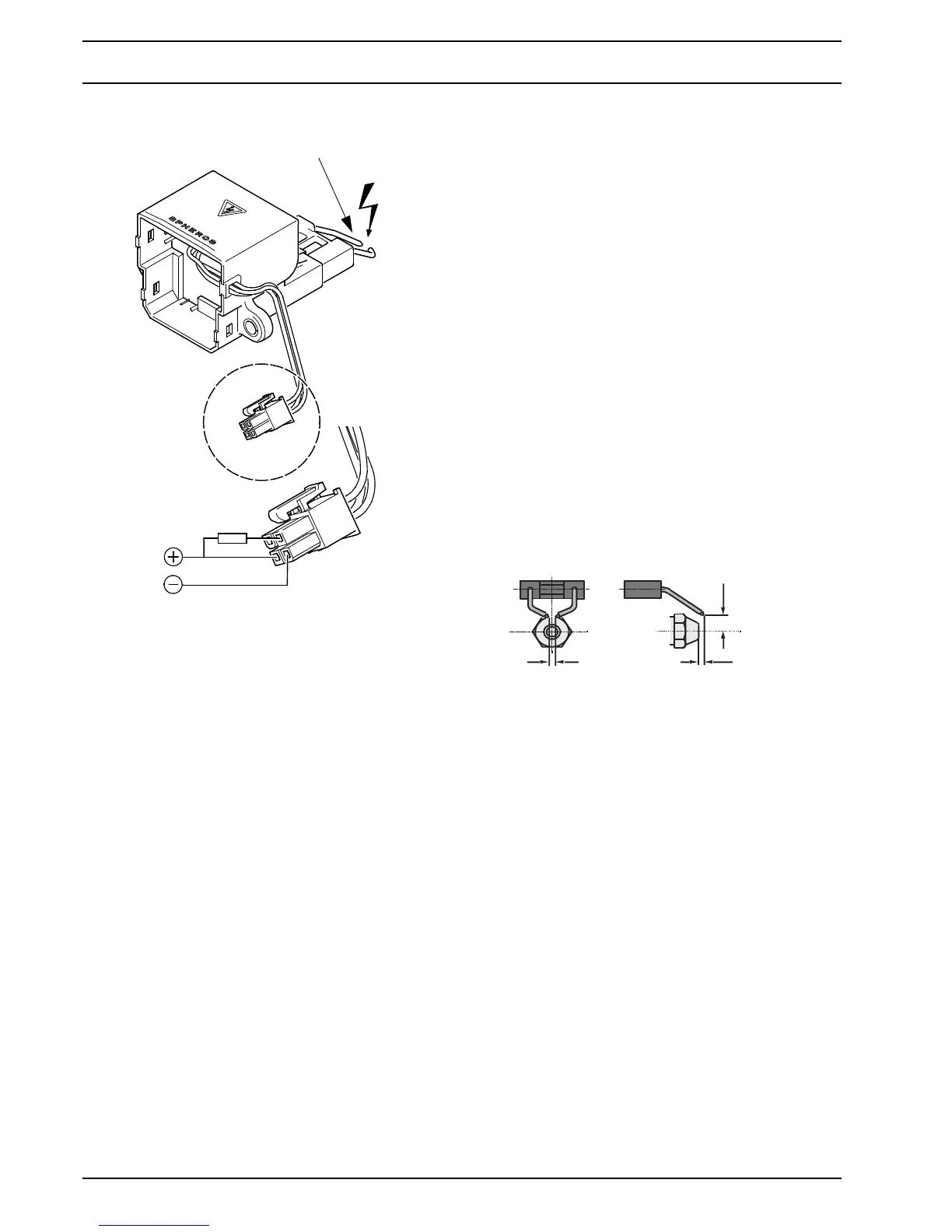

5.5.8 Ignition electrode inspection

NOTE

The ignition electrode insulation may not be damaged.

Ignition electrodes not functioning properly must be

replaced.

ATTENTION

Do not damage the electronic ignition unit when removing

the ignition electrode.

Inspection

• Remove burner (see 8.2)

• Check distance of the electrode tip to the atomizer

nozzle (see Fig. 506).

• Check the distance between the electrodes

(see Fig. 506).

NOTE

The distance between the electrodes may b measured

using checking gauge, item number 310646.

• If needed, lift off ignition electrode (3, Fig. 805) from

the electronic ignition unit by twisting a screwdriver

sideways (see Fig. 804).

• Inspect the ignition electrode insulation for damage.

• Functionality is verified while inspecting the electronic

ignition unit.

5.5.9 Flame detector inspection

NOTE

In case of contamination the glass body of the flame

detector and the inspection glass in the disc

(see Fig. 507) must be cleaned.

The flame detector is permanently integrated into the

control unit and cannot be replaced.

The error diagnosis is possible only via the flash code

(error code 5).

Fig. 505

Ignition electrode 13,000 Volt

10 kOhm

Fig. 506

4

5

8

±0,5

±0,5

+1

Loading...

Loading...