Thermo E 200 / 320 5 Troubleshooting and error correction

513

5.5.10 Fuel pump inspection

ATTENTION

The pump pressure of the fuel pump is adjusted to a

fixed value in the factory.

It is not permitted to change the pump pressure.

The fuel pump and fuel hoses must be replaced after

5 years.

An admixture of up to 30% FAME to Diesel fuel is permit-

ted.

NOTE

If FAME is used, commonly designated as biodiesel,

the fuel pump and fuel lines must be replaced accord-

ing to the latest technical information / notification.

The following inspections should be performed prior to

testing the pump pressure:

•Is the CO

2

content properly adjusted?

• Do the combustion chamber, atomizer nozzle and

burner motor correspond to the heating capacity

class?

• Does the motor reach nominal speed?

• Is the fuel temperature 15...25°C?

• Are available check valves in the fuel supply and

return lines opened?

• Was the fuel filter in the fuel supply line replaced?

• Are the filters (screens) in the pump inlet clean?

• Is the fuel delivered without bubbles?

Attach a transparent hose for testing.

• If the specified exhaust values cannot be reached

after inspection and consideration of this error

sources, the fuel pump is to be replaced.

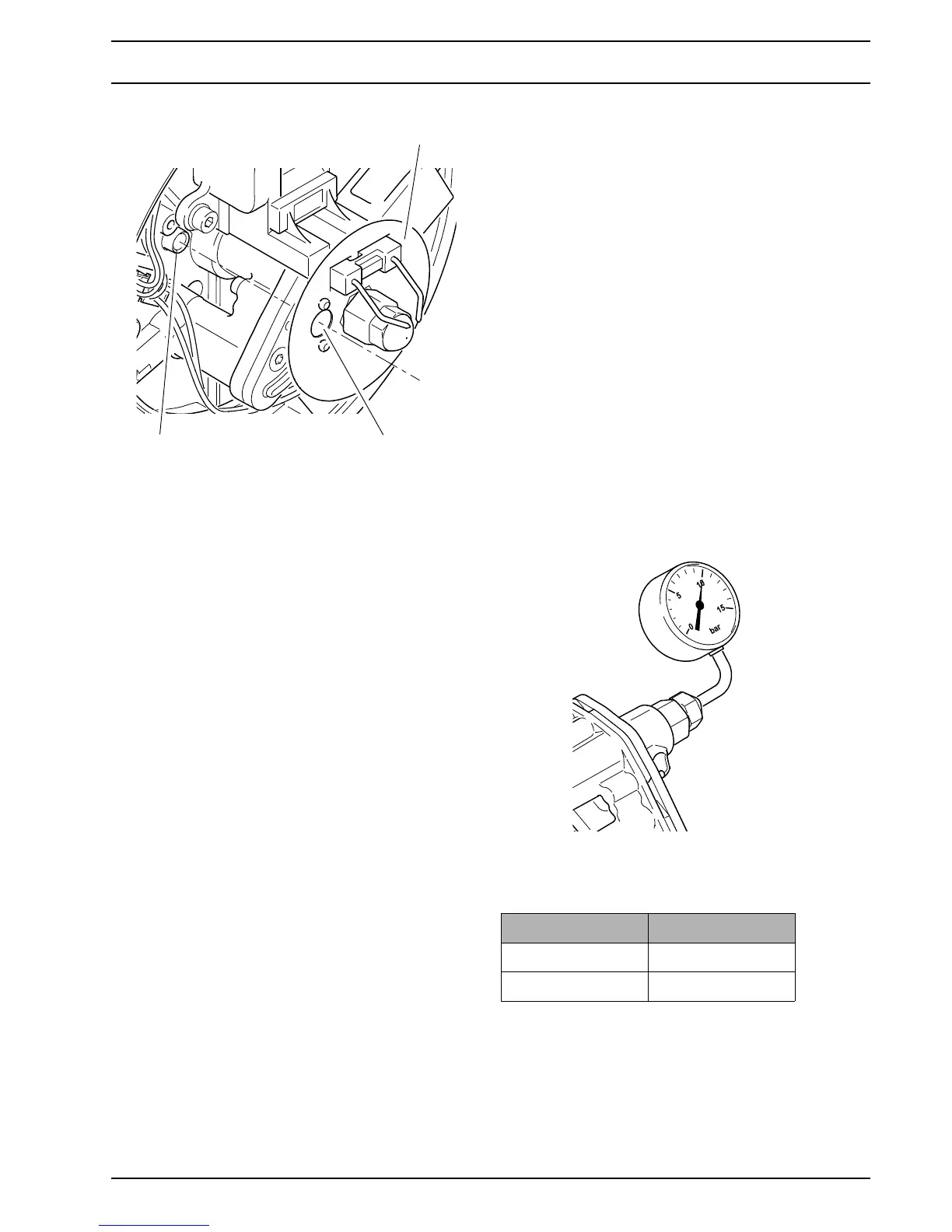

The pump pressure can be checked as follows.

The pump pressure adjustment is not permitted.

• In a workshop (not in the vehicle) fix the burner head.

• Disconnect motor and solenoid valve connectors from

control device.

• Ensure fuel supply.

• Screw a pressure gauge into the nozzle holder.

• Hook-up the motor and the solenoid valve with a 24V

power supply (Observe the rotation direction of the

motor! Pointer on the fan wheel).

• Read the pressure at the pressure gauge.

• Dismantling in reverse order.

Fig. 507

Flame detector

Window

Disc

Fig. 508

At 24.0V Pump pressure

Thermo E 200 8 +1 bar

Thermo E 320 9 +1 bar

Loading...

Loading...