3 Description of assemblies and components Thermo E 200 / 320

302

3.1 Burner

The burner consists of components

• Burner motor

• Combustion air fan

• Fuel pump with solenoid valve

• Atomizer nozzle

• Electronic ignition unit with ignition electrode

• Control unit with flame detector

• Disc with inspection glass

• Nozzle block preheater (optional)

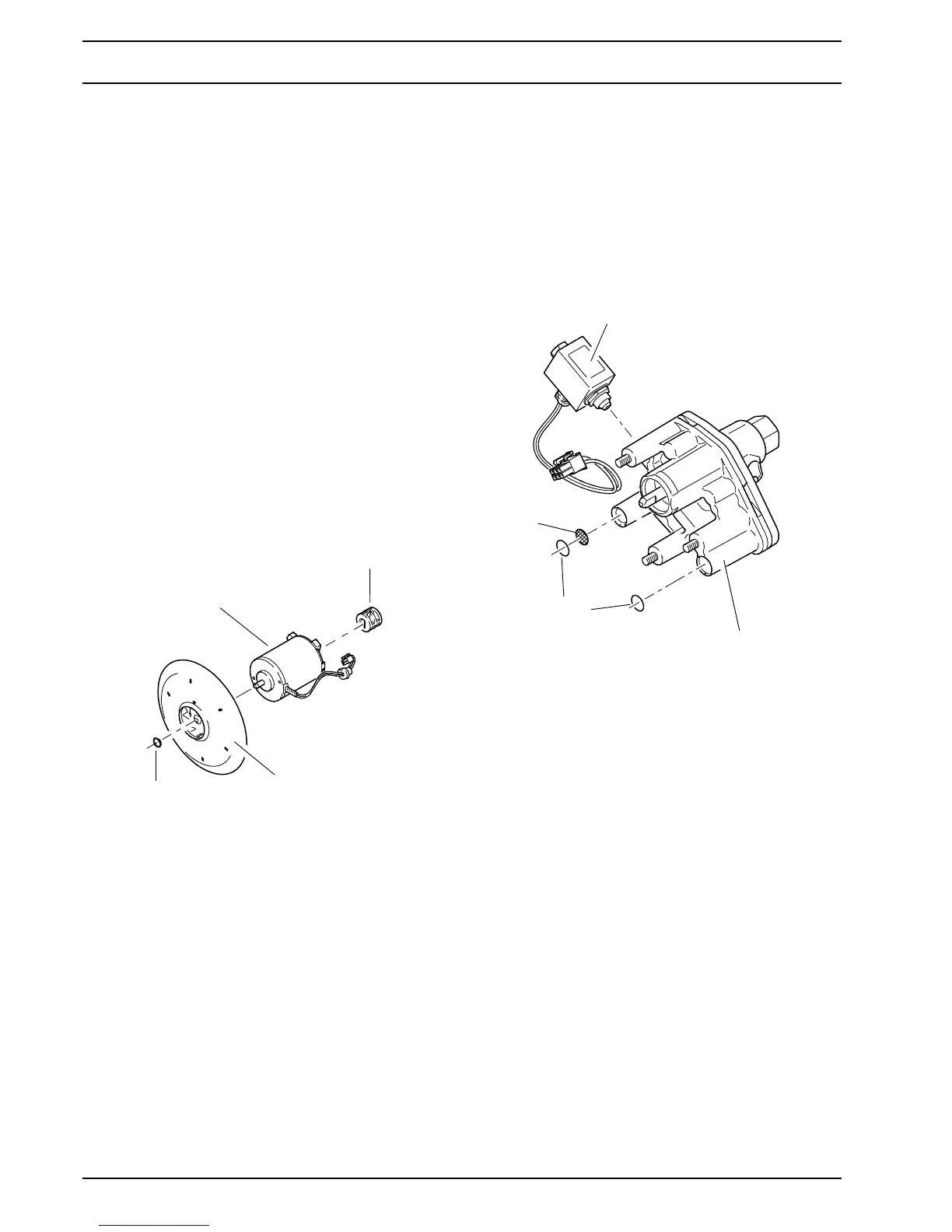

3.1.1 Combustion air fan

The combustion air fan transports the air required for

combustion from the combustion air intake to the combus-

tion chamber.

The combustion air fan consists of burner motor and fan.

Air is drawn in through the air intake opening in the hood.

The air intake opening is equipped with a splashguard, a

protective screen and a hot air elbow.

Two different motors are assigned to the different heating

capacity classes of the Thermo E series. This assignment

is clearly beyond the material number. The motors must

not be interchanged.

NOTE

The positioning of the engine to the housing is safely

defined by a pin and a hole (see Fig. 803).

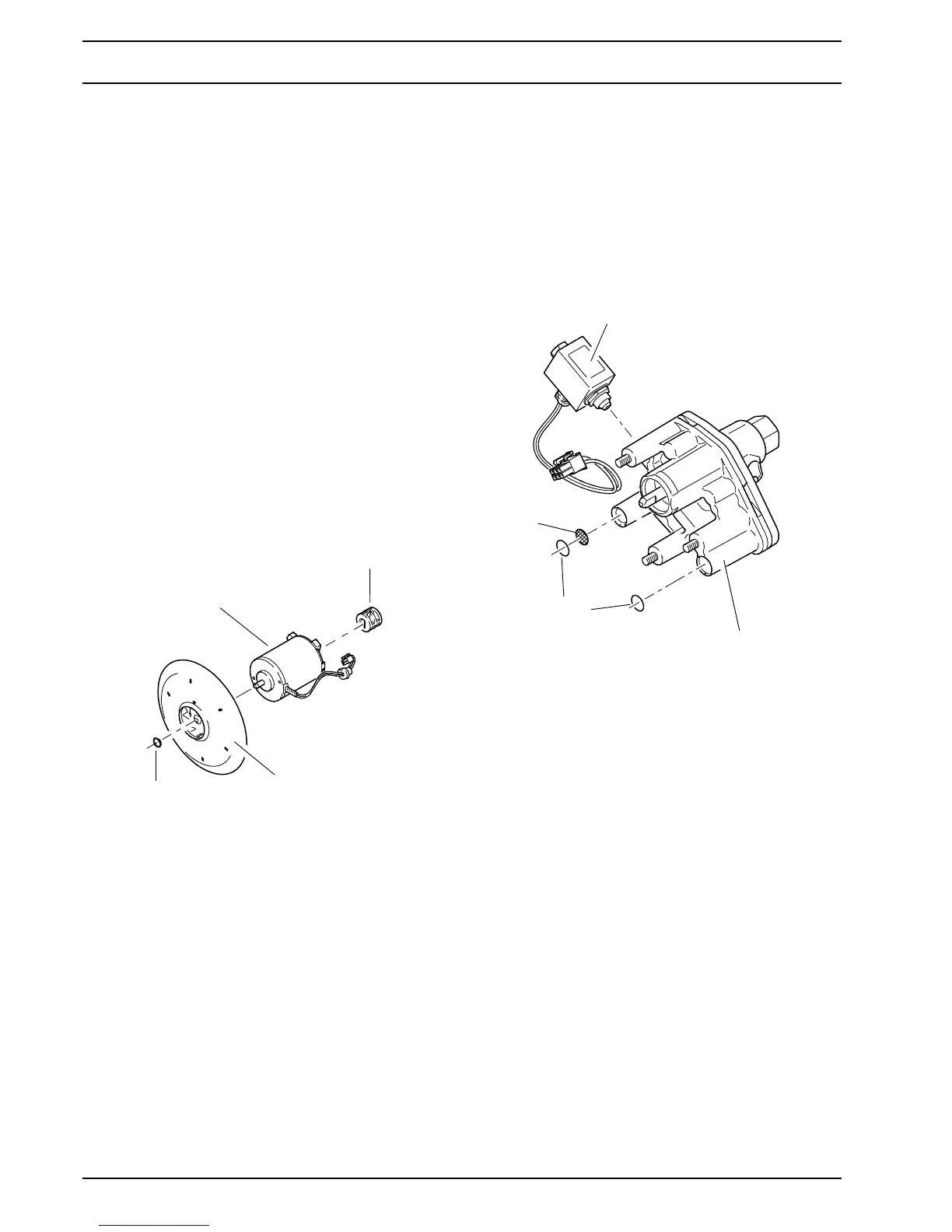

3.1.2 Fuel pump

The fuel pump is responsible for fuel supply.

The pump is driven by the burner motor via a coupling.

Fuel is compressed in the fuel pump to approx. 10 bar and

atomized via the atomizer nozzle.

The solenoid valve integrated into the fuel pump opens

and closes the fuel supply to the atomizer nozzle.

Identical fuel pumps are installed in heaters of both

heating capacity classes.

The fuel pump is designed for dual-line operation (fuel

supply and return line).

ATTENTION

If the heater is operated with

– a long fuel supply line (> 15m)

– check valves in the fuel supply and return line

(> 0,07 bar)

– a fuel filter in the fuel supply line

the fuel supply line and fuel filter are to be filled prior

to first heater start-up (see 8.14.1).

Burner motor

Fan

Shaft

circlip

Coupling

Solenoid valve

Fuel pump

Screen

O-ring

Loading...

Loading...