Thermo E 200 / 320 3 Description of assemblies and components

305

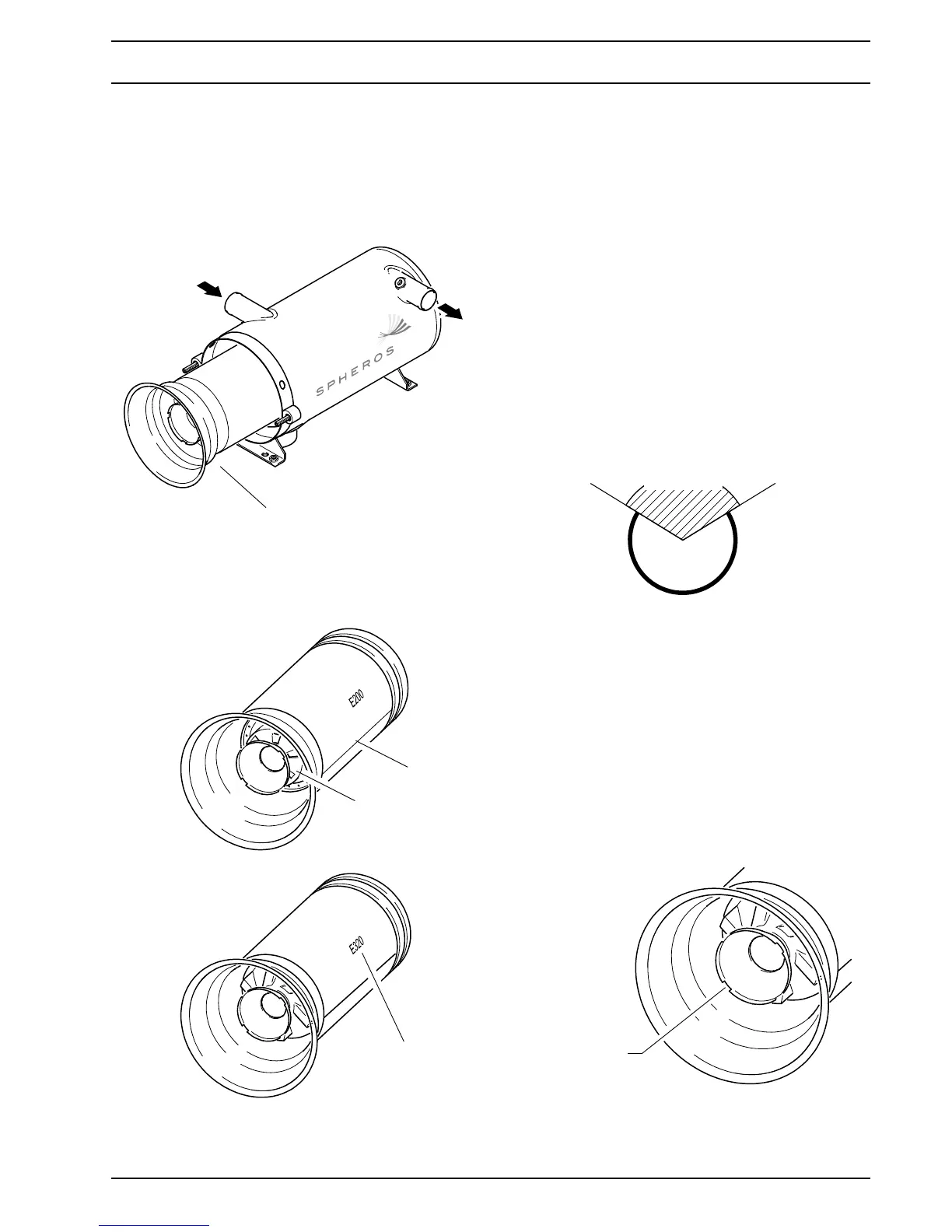

3.3 Combustion chamber

The combustion chamber is used for generation and

combustion of the fuel air mixture. The generated exhaust

gas heats the coolant flowing through the heat exchanger.

Depending on heating capacity class, different combus-

tion chambers are used.

They have different swirler (E 200 sheet metal, E 320 cast

iron). The combustion chamber of the Thermo E 320 is

additionally equipped with a flame stabilization pipe.

The combustion chambers have an identification stamp

according to the associated heater (E 200 or E 320).

CAUTION

Heater operation with a combustion chamber of a

other heating capacity class is not permitted.

NOTE

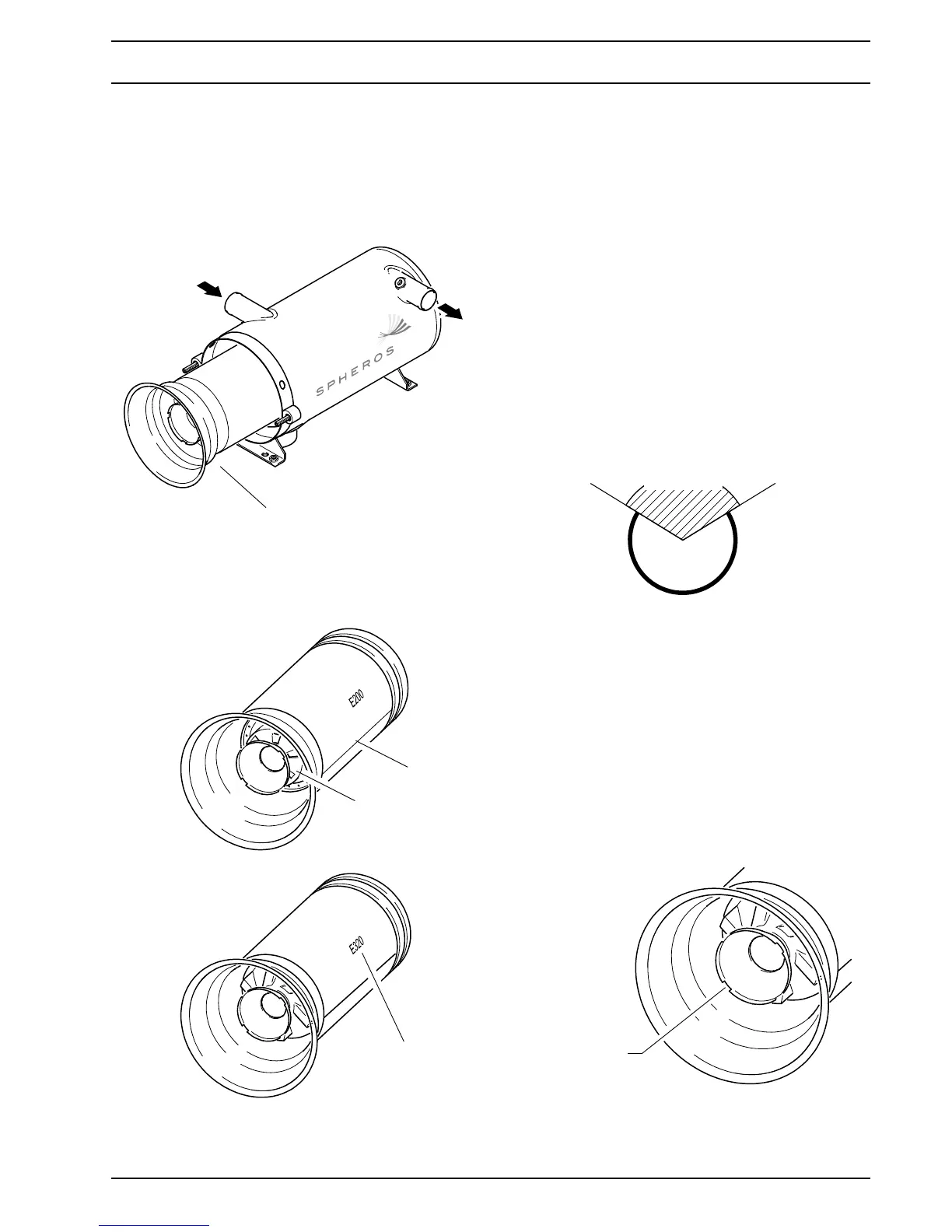

The combustion chamber should be inserted into the

heat exchanger in such a way that its welding seam is

positioned between 2 and 10 o clock (not upwards!).

A position change during maintenance is permissible

and affects the expected service life of the combus-

tion chamber positively (see graphic below).

NOTE

It should be ensured that none of the 4 cut-outs of the

combustion chamber head points vertically down-

wards (see graphic below).

Dripping from nozzle fuel is so collected in a reservoir

between disc and burner head and will be burned at

the next burner operation instead to soil the heater.

.

Combustion chamber

Identification

of the heating

capacity class

Welding seam

Swirler

32 KW

20 KW

permissible

not permissible

Position of welding seam

Cut-out positions

on the combustion

chamber head

in installed position

Loading...

Loading...