5 Troubleshooting and error correction Thermo E 200 / 320

514

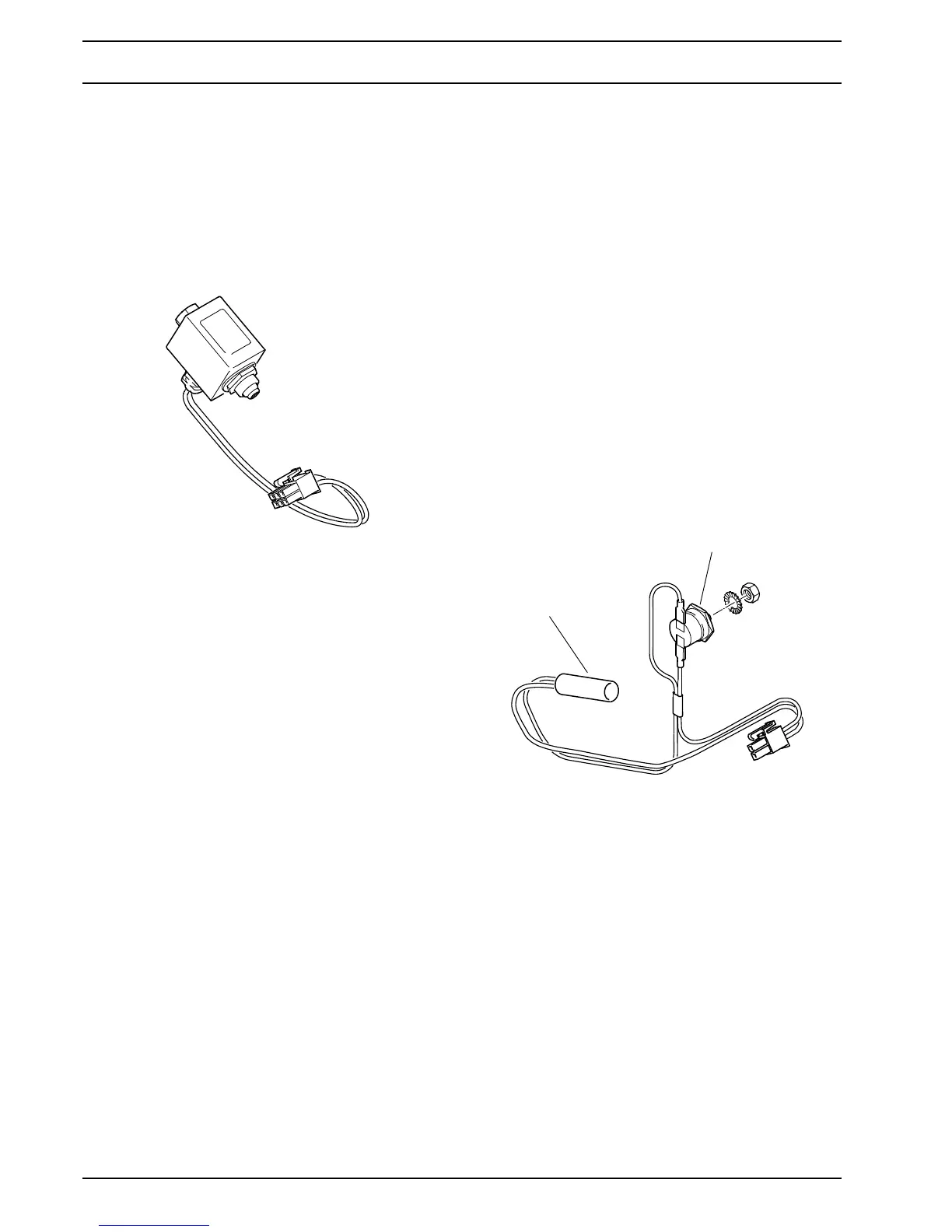

5.5.11 Solenoid valve inspection

ATTENTION

The coil of the solenoid valve can heat up in switched-

on condition.

The solenoid valve must only be completely replaced.

In case of replacement or assembly a new gasket ring

must be used.

NOTE

Due to system characteristics draining the space between

solenoid valve and nozzle bore may cause fuel dripping

from the atomizer nozzle for a short period of time.

A leaking valve seat of the solenoid valve can be indicated

by smoke development in the heater during the purge

cycle. Fuel drips from the atomizer nozzle.

A not closing solenoid valve may cause heater deactiva-

tion during purge cycle with heater interlock activation.

The electrical function of the solenoid valve can be

checked manually.

Manual inspection:

• Remove burner (see 8.2).

• Disconnect the solenoid valve plug from the control

unit.

• Apply 24V direct voltage an check electrical function:

– Opening voltage: ab 17.0 Volt

– Power consumption at

24V and 20°C: 9 Watt

– Nominal current at 24V: 0.37 Ampere

The solenoid valve must audibly open, when voltage

is applied.

• Reconnect the solenoid valve plug to the control unit.

• Install burner (see 8.2).

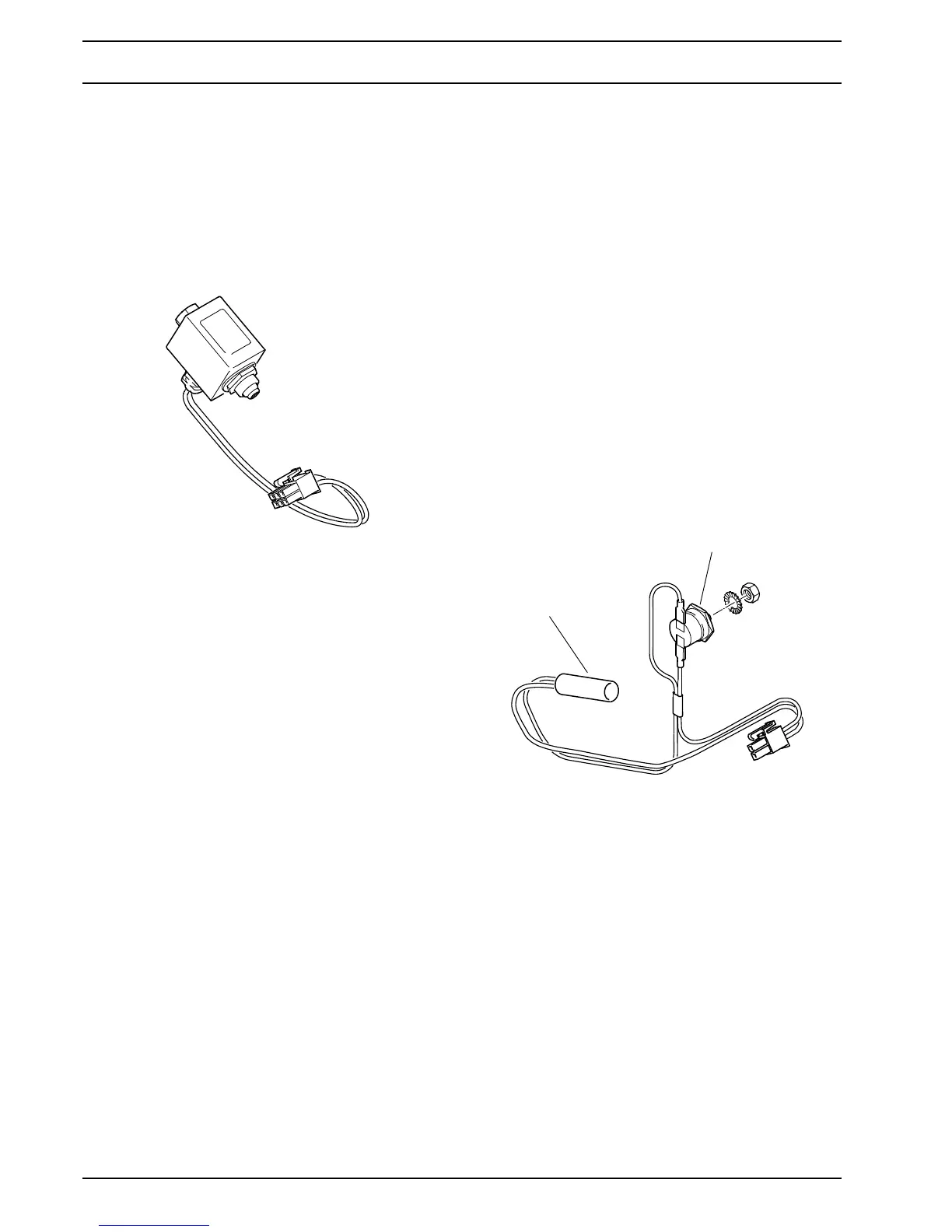

5.5.12 Nozzle block preheater inspection

NOTE

At a temperature of < 5°C the heating element in the

nozzle holder is switched on via a temperature sensor.

The heating duration depends on the intake air tempera-

ture and on the reflected by the burner heat.

Above 8°C the thermostat turns the preheater off.

The power consumption of the heating element is at 24V

approx. 80W.

Inspection

• Remove burner head.

• Disconnect the nozzle block preheater plug from the

control unit.

• Connect an ohmmeter to the plug.

• Bridge over the thermostat

• Resistance max. 8 Ohm.

Fig. 509 Solenoid valve

Abb. 510 Nozzle block preheater

Heating element

Thermostat

Loading...

Loading...