48

Shock Assembly and Bleed

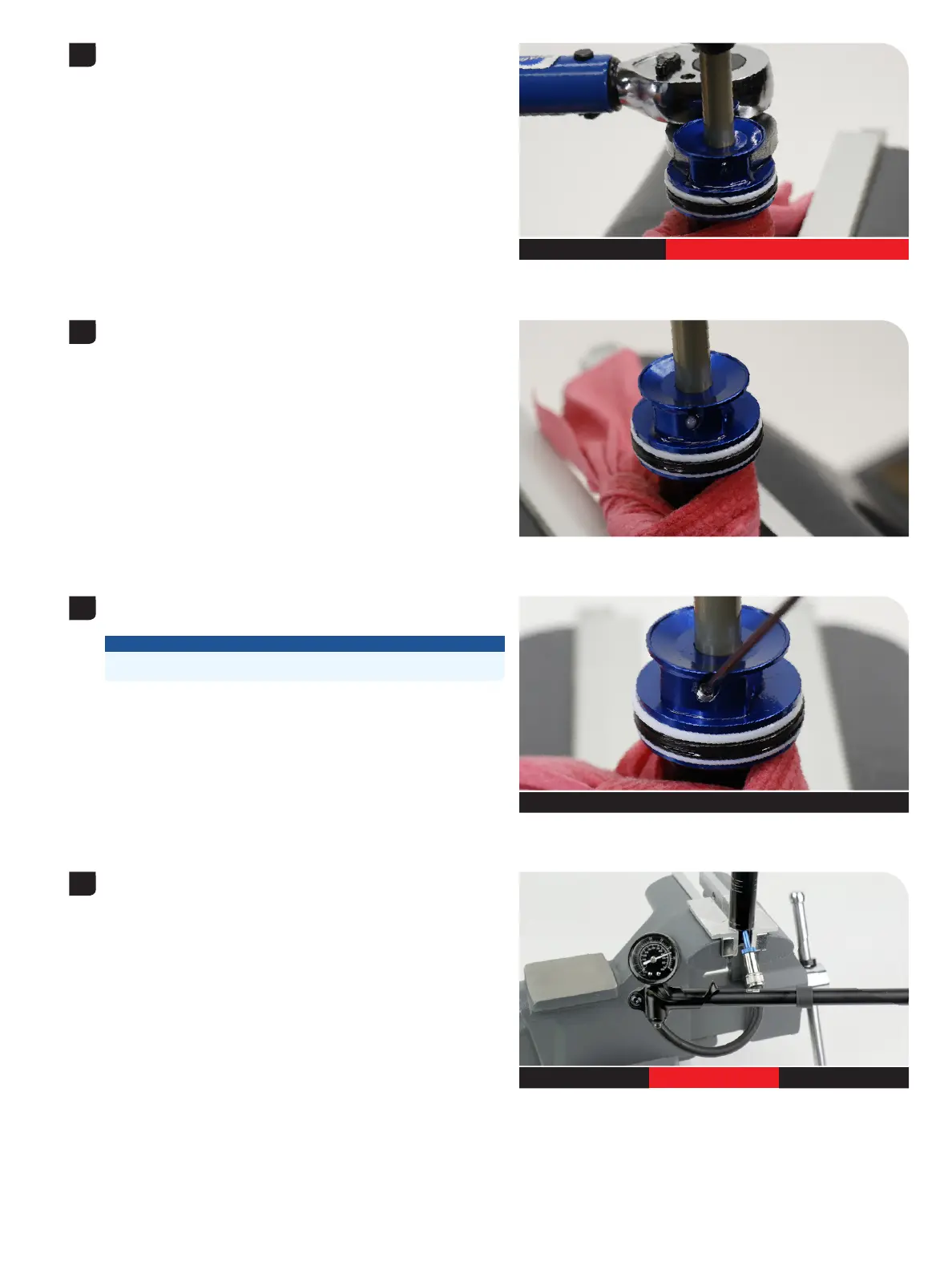

Tighten the seal head/air piston.

Install the crowfoot onto the torque wrench at a 90° angle to the Install the crowfoot onto the torque wrench at a 90° angle to the

handle to ensure an accurate torque reading.handle to ensure an accurate torque reading.

Allow air bubbles to escape from the bleed port in the seal head.

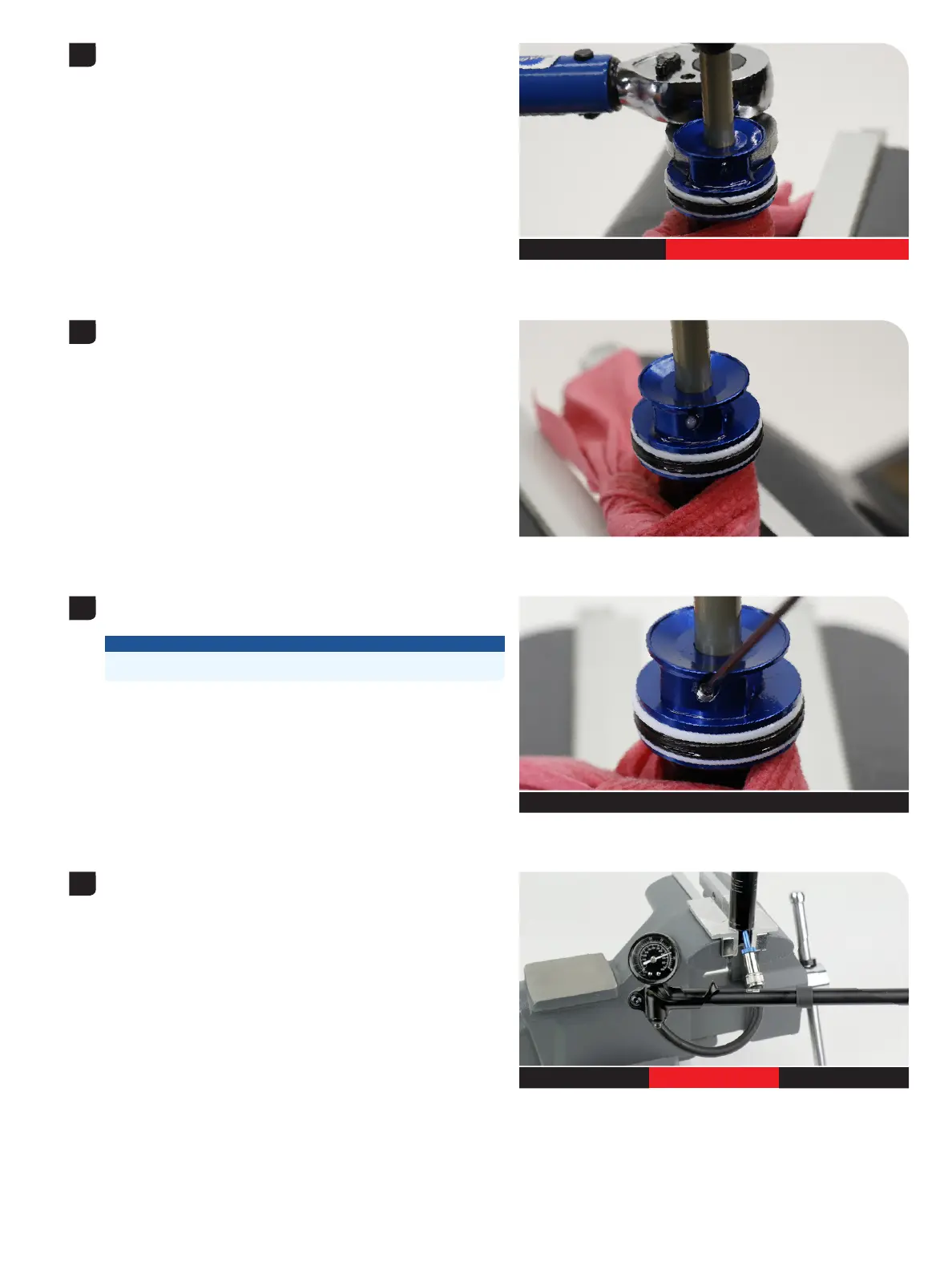

Insert the new compression ball into the bleed port.

Thread the bleed screw into the bleed port until you feel it touch the

compression ball, then tighten the bleed screw an additional ½ turn.

NOTICE

Overtightening the bleed screw can damage the compression ball.

Remove the damper body from the SIDLuxe Body Vise Block.

Pressurize the damper body.

If you have the proper fill equipment, you may substitute air with

nitrogen.

Once you have pressurized the shock, remove the air valve adapter

tool from the air fill port before removing it from the shock pump.

Separating the pump from the adapter first will cause all of the air to

escape from the shock.

4

19 mm (≤0.25 inches thick) 28 N·m (250 in-lb)

5

6

2 mm

7

Shock pump 500 psi SIDLuxe adapter tool

Loading...

Loading...