5

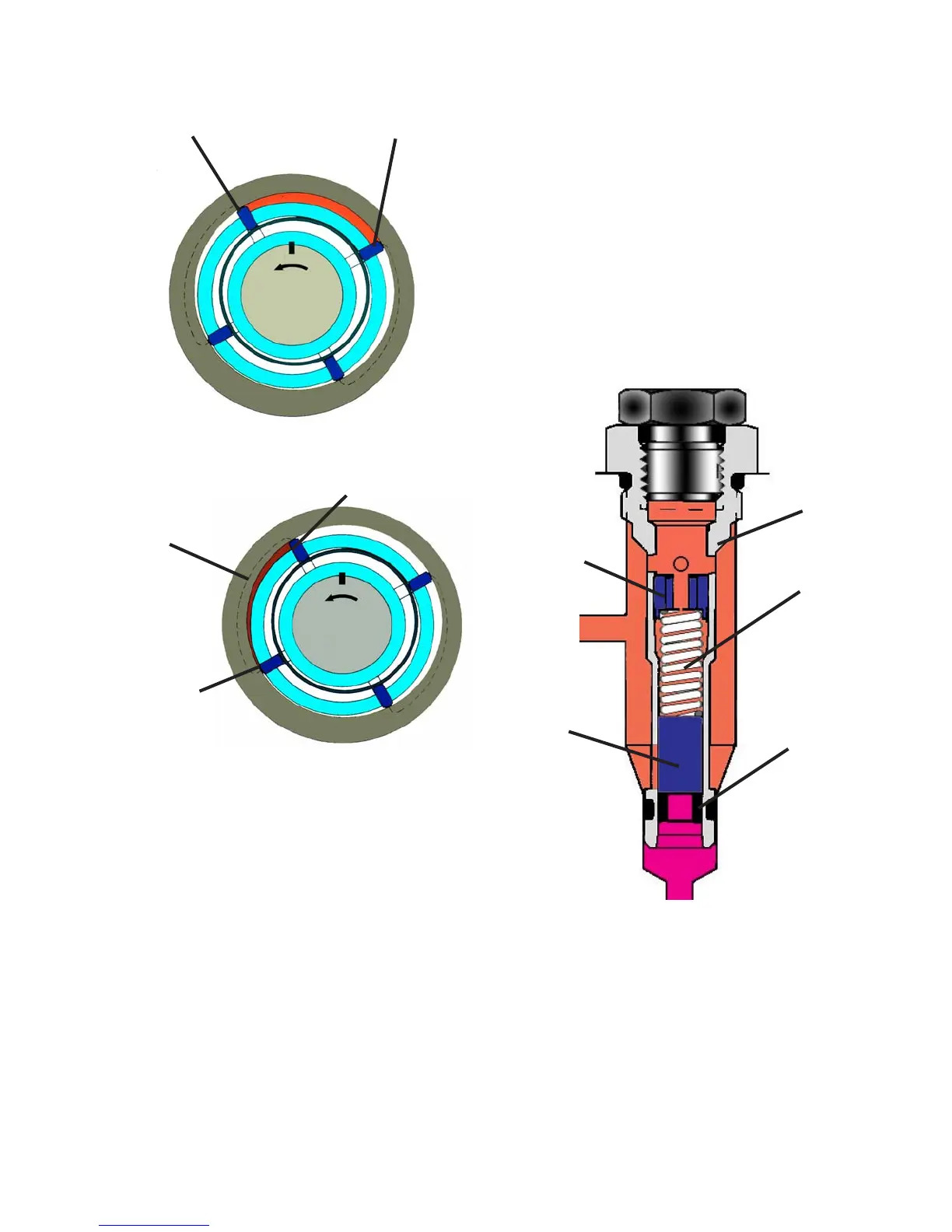

Fig. 1.6b

Blade 1

Blade 2

Fig. 1.6c

Blade 1

Blade 2

Outlet Port

volume between blades 1 and 2 now be-

gins to decrease forcing the fuel charge

into the kidney slot. Pressurization contin-

ues until blade 2 passes out of registry with

the outlet kidney slot.

A small drilling in the face of the porting

plate allows transfer pressure to flow into

the counter bore in the blade carrier where

the blade spring is located. This provides

equal pressure at both ends of the blade

to provide pressure balancing.

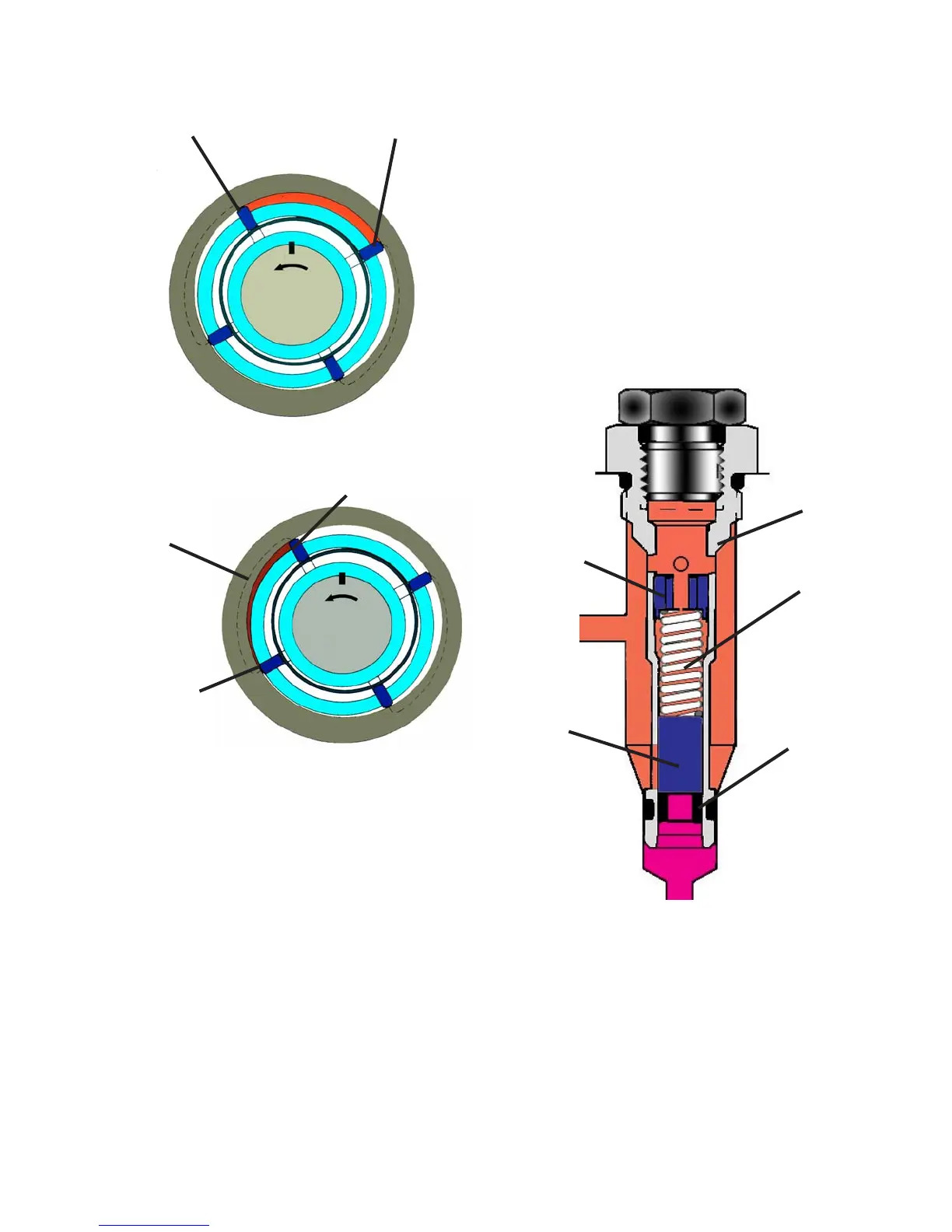

E. Transfer Pump Regulator (Figure

1.7)

The DE pump utilizes a transfer pump pres-

sure regulator similar to the type used in

the DS and DB/DC pumps. It consists of a

regulator sleeve that houses a regulating

piston, piston stop, spring and an adjust-

ing plug assembly. The sleeve also incor-

porates a regulating slot and has a filter

screen before the piston stop to prevent

debris from lodging in the regulating slot.

As mentioned earlier, transfer pump pres-

sure is regulated after passing through the

DE and DS pumps as opposed to the other

D series pumps where the pressure is

regulated prior to flowing through the pump.

After filling the various circuits within the

injection pump, the pressurized fuel passes

through the end of the regulator sleeve

Regulating

Sleeve

Assembly

Adjusting

Plug

Assembly

Piston

Stop

Spring

Regulating

Piston

Fig. 1.7

Loading...

Loading...