SECTION 3 – CLEANING AND PARTS

INSPECTION

General

The Temperature Sensor and Fuel Control So-

lenoid should be wiped clean and placed in a

parts tray. These items should never be sub-

merged in harsh cleaning solvents or solutions.

The remaining DE pump components can be

cleaned using standard cleaning practices and

solvents that would be used for other

Stanadyne D Series pumps. NOTE: The DE

pump contains many small components. If

parts are put in a wire basket for submersion

in cleaning solution, be sure that the mesh is

small enough so parts will not fall through. After

cleaning, blow-dry all components with clean,

filtered, dry compressed air. Inspect compo-

nents as outlined herein, replace as neces-

sary and dip all parts in clean calibrating fluid

and place in a parts tray.

A. Component Inspection

Discard all o-rings seals, gaskets and adjust-

able spacers. Inspect springs for fretting, wear,

distortion or breakage. Examine all moving

parts for excessive wear, scoring, cracks and

fretting. Replace damaged or excessively worn

parts as necessary. Always check for signs of

contamination. Communicate these findings

with your customer so that he can improve

fuel handling and filtration practices to better

protect his equipment. NOTE: The illustrations

that follow depict typical locations where com-

ponent wear might be observed in DE pumps.

Damage and wear is not limited to these ar-

eas nor is the wear shown meant to indicate

that these parts require replacement. The ap-

pearance of a part is but one measure of

whether the part needs to be replaced. An-

other more important measure is whether the

pump can be calibrated on the test bench.

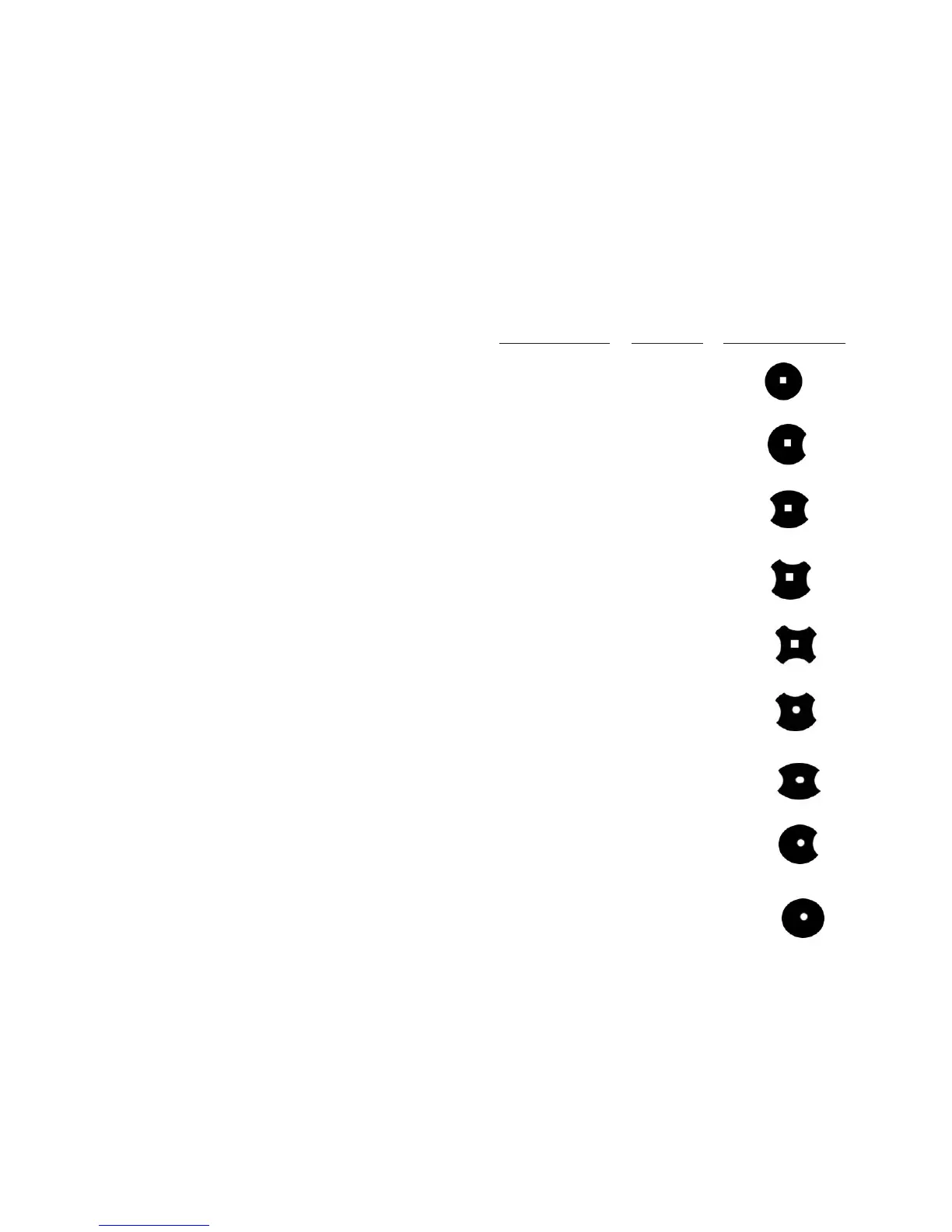

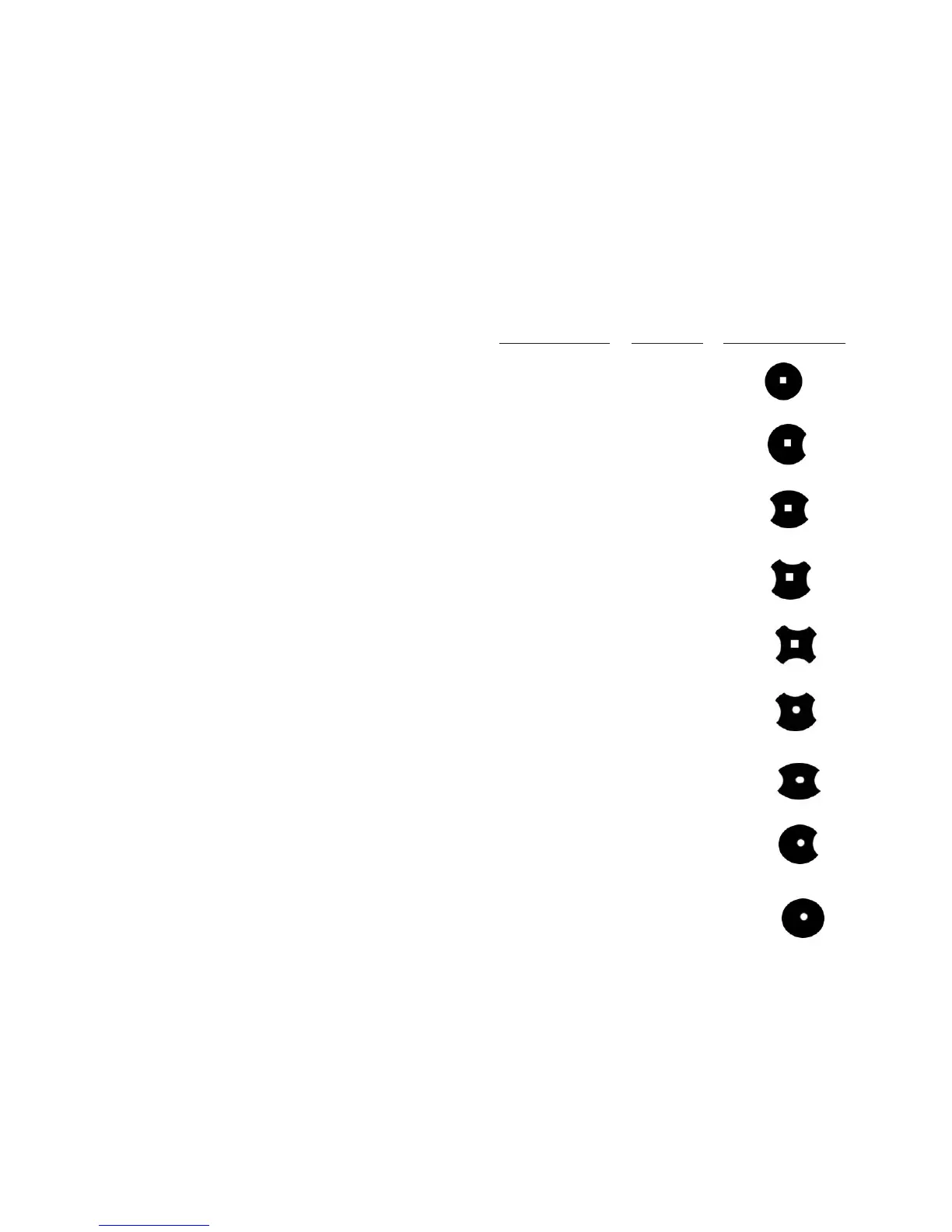

B. Poppet Valve Shims

During disassembly the poppet valve shim(s)

should have been removed and their thick-

ness measured and noted. If they are subse-

quently misplaced, replacement shims are

available as noted and on individual specifi-

cation. Always use the same thickness shim(s)

as replacements. (The average shim stack up

is between .048 and .050 inches.)

Thickness

Part number (inches) Configuration

29653 0.010

29654 0.012

29655 0.015

29656 0.018

29657 0.020

29658 0.022

29659 0.025

29660 0.028

29661 0.0305

C. Supplementary Inspection

1. Housing – Inspect the housing for cracks or

signs of damage. Check head locking and lo-

cating screw holes for erosion or other signs of

damage. Inspect the inside of the housing where

25

Loading...

Loading...