SECTION 5 - TEST BENCH

REQUIREMENTS AND PROCEDURES

A. Special Test Equipment Requirements

To test the DE pump, the following special test

bench accessories are needed in addition to a

test bench meeting both ISO 4008 standards

as well as Stanadyne‘s requirements as outlined

in the Service Policies and Procedure Manual.

DE pumps are tested with 0.5 mm orifice plate

36951 Low Dead Volume Calibrating Injectors,

having a factory set opening pressure of 250

bar/3500 p.s.i.

Part

Number Description

33497 Transfer Pump Pressure Tap

36260 Drive Adapter Kit

36263 Hall Sensor Kit

36269 Electronic Control Package

36274 Inlet and Return Fitting Kit

36275 Timing Pin

36464 Housing Pressure Tap

70340 High Pressure Pipes

The 36263 Hall Effect Sensor Kit contains a

bracket assembly and a 36262 Hall Effect

Sensor. Only the Hall Effect Sensor is avail-

able seperately for service replacement. (Fig-

ure 5.7)

The 36260 Drive Adapter Kit contains a drive

adapter, a 36258 Four Tooth Wheel and a

36257 Six Tooth Wheel. Both tooth wheels are

available seperately for service replacement.

The 36269 Electronic Control Package con-

tains the following components:

Breakout Cable 36264

DAC Cable 36265

DE Pump Control Module

Laptop Computor

USB, External Floppy Drive

Only the Breakout and DAC cables are avail-

able seperately for service replacement.

Reference Instruction Manual 99851 for addi-

tional details on the 36269 Electronic Control

Package contents and use.

B. Test Bench Mounting Instructions

Pump mounting plates are provided by the vari-

ous test bench manufacturers, not by

Stanadyne. DE pumps use a triangular mount-

ing flange with a 98mm bolt circle and a 50mm

pilot diameter (same as most DB4 pumps).

The drive adapter is the same as used for test-

ing DB2 pumps for the General Motors 6.2/

6.5L apllications.

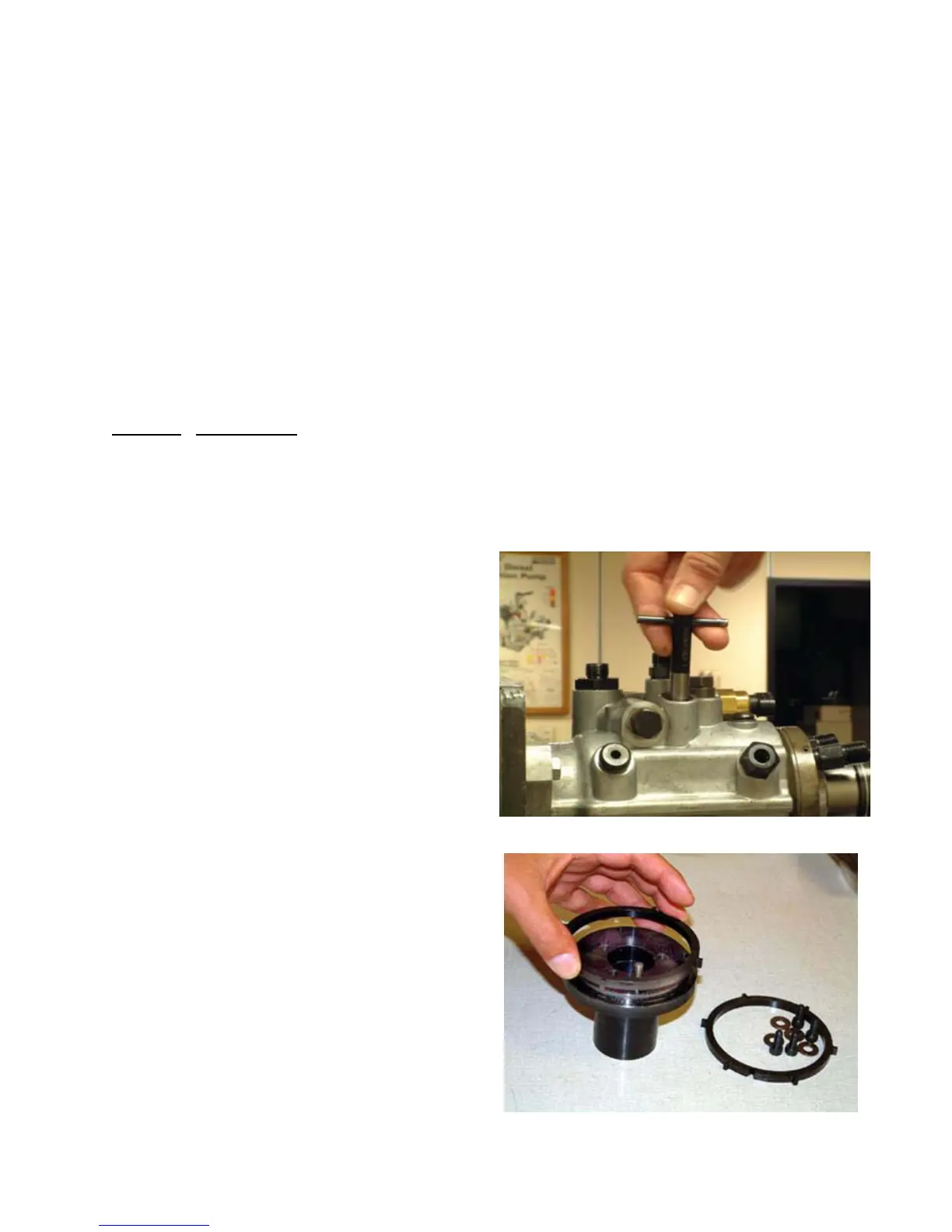

Step1. Clamp the test bench 19965 pump hold-

ing fixture in a suitable vise and mount the DE

pump to the fixture.

Step 2. Remove the timing access hole plug

from the top of the pump. Insert the 36275

Timing Pin into the bore and slowly rotate the

drive shaft until the pin engages with the slot in

the drive shaft. Ref. Figure 5.1.

Fig. 5.1

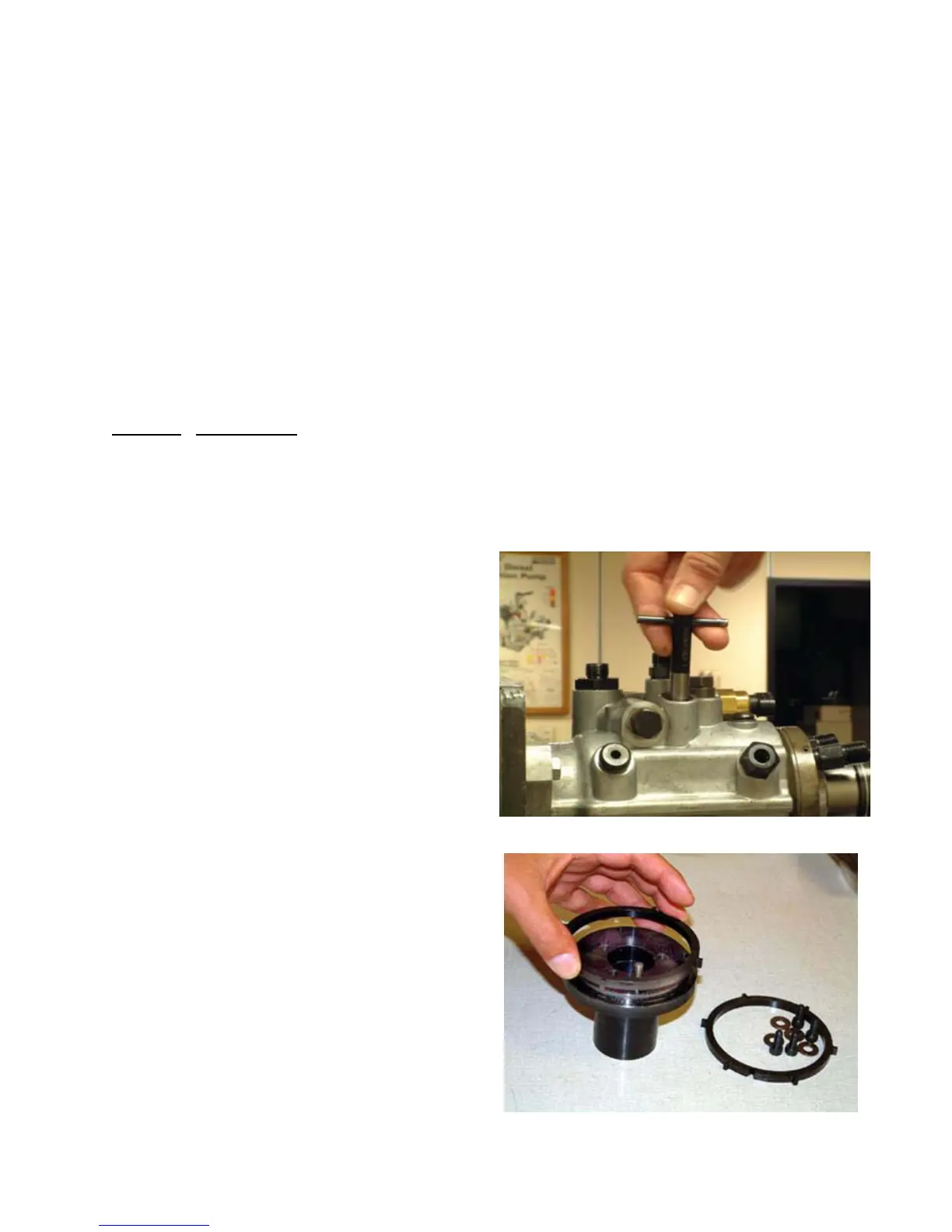

Fig. 5.2

46

Loading...

Loading...