During discharge the pressure wave

devolped by the pump unseats the plate

allowing unrestricted flow of fuel to the in-

jector. At the end of injection the spring

seats the plate. Any return waves due to

the closing of the injector would need to

pass through the orifice before entering the

pump. The orifice causes an attenuation

of the wave thus lessening the possibility

of a strong secondary wave returning back

to the injector which could cause an engine

damaging secondary injection.

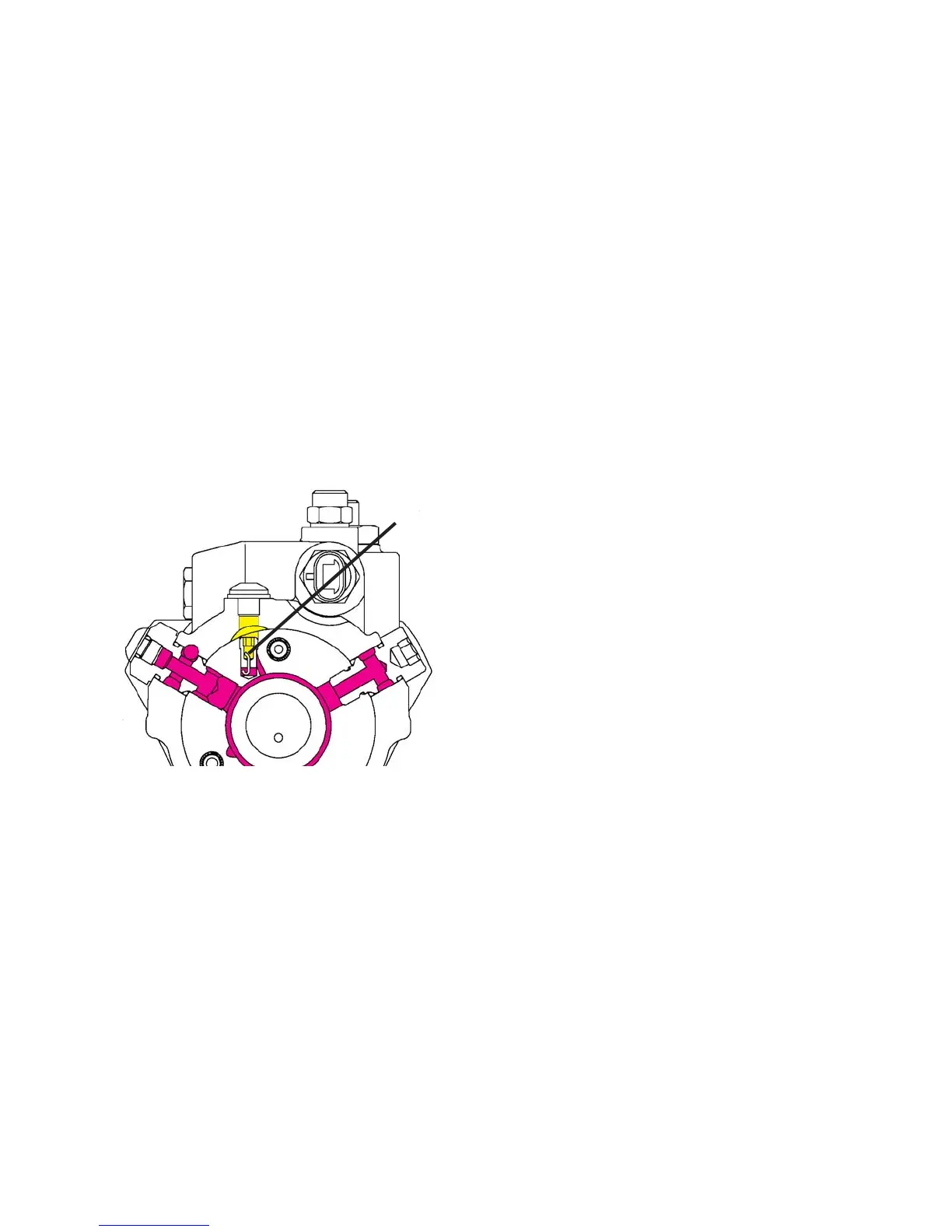

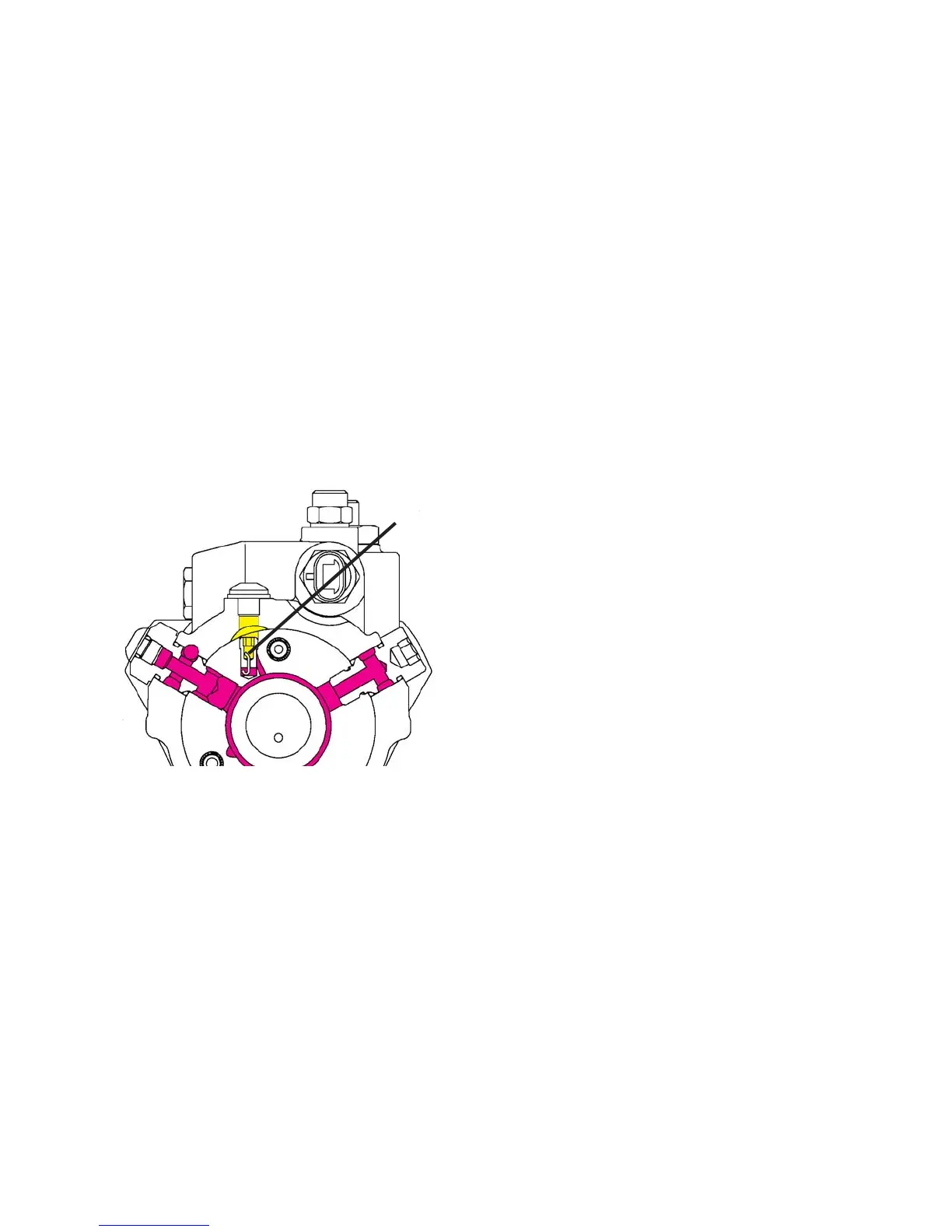

I. Return Fuel Circuit (Figure 1.12)

Fuel fills the DE pump housing due to leak-

age of transfer pump pressure plus injec-

tion pressure between fitted components

within the pump such as the head and ro-

tor assembly, and the pumping plungers.

To adjust this flow to a specific range for

optimum pump operation, and provide a

means of purging any air entrained within

the fuel, a vent wire system is employed.

Fuel under transfer pump pressure is di-

rected into the vent passage at the top of

the hydraulic head which connects with the

housing cavity. Flow through the passage

8

Vent Wire

Fig. 1.12

is controlled by the vent wire assembly.

The amount of return fuel can be adjusted

by varying the wire size used in the vent

wire assembly; the smaller the wire the

greater the flow through the orifice and

vice versa. The vent wire assembly is

available in several sizes in order to pro-

vide adjustment of the return flow to the

quantity called for on the specification.

Note that this assembly is accessible by

removing the button head cap screw be-

tween the two head locking screws.

Since the vent wire assembly is located

in the highest point of the transfer pump

circuit any air entering the transfer pump

gravitates to the vent passage. The air,

plus a small quantity of fuel passes

through the orifice and then from the

housing through the return line connec-

tor and eventually back to the fuel tank.

Housing pressure is maintained by a

spring loaded valve in the return line con-

nector/housing pressure regulator lo-

cated on the top of the pump housing.

The function of the return line connector/

housing pressure regulator is only to con-

trol the pressure within the housing. The

vent wire assembly on the other hand only

adjusts the volume of return flow from the

pump.

J. Dynamic Pump Timing Ad-

vancement (Figure 1.13 and

1.14)

In all pump-line-nozzle fuel injection sys-

tems, the actual beginning of fuel deliv-

ery at the nozzle follows, after a short

period of time, the start of pumping. This

difference between start of pumping and

start of injection,(known as Injection Lag)

is the result of the speed of the pressure

wave through the length of the injection

line. Since the speed of the pressure

wave remains constant (1500 meters/

second for diesel fuel) , injection lag

Loading...

Loading...