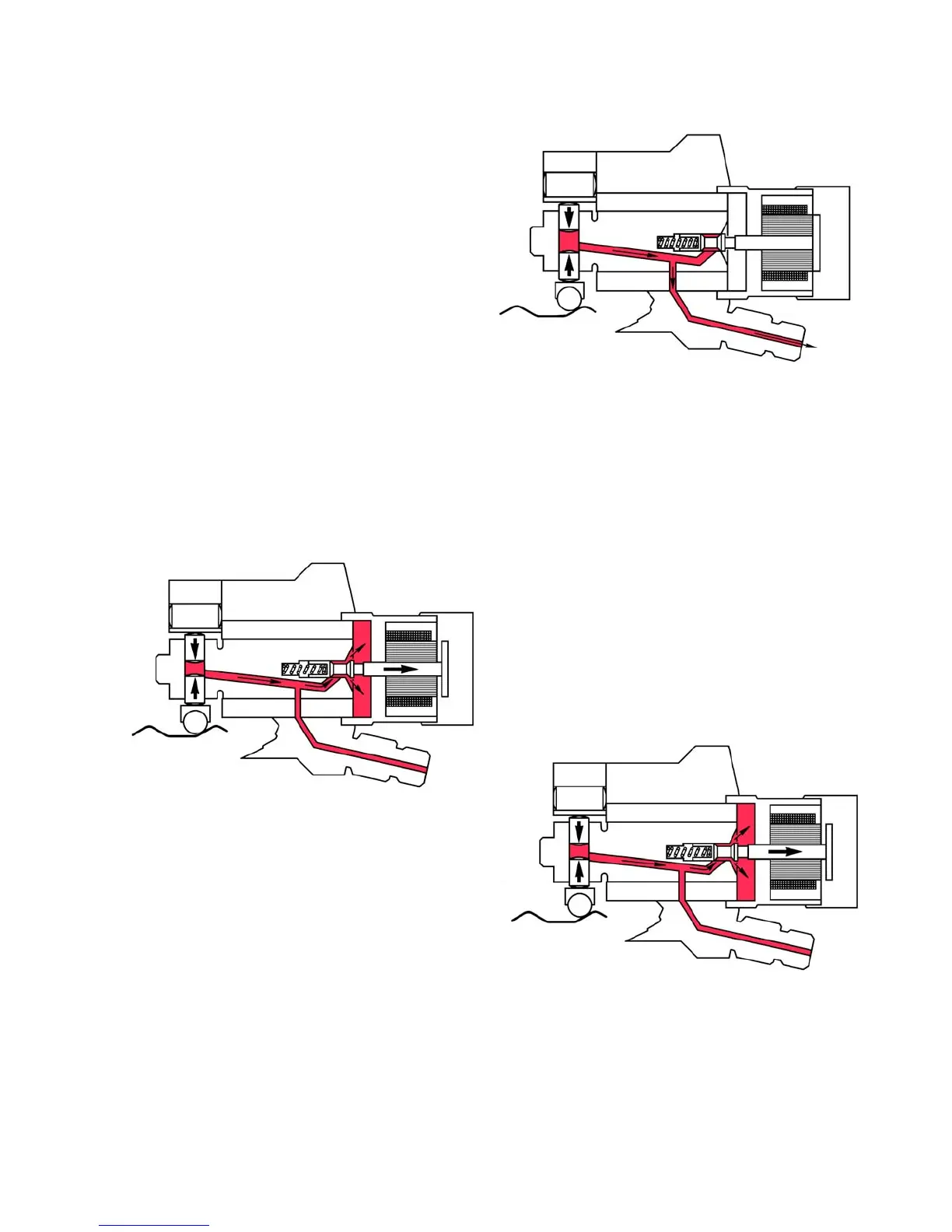

The operation of the high-speed fuel con-

trol solenoid during charging is pictured in

Figure 1.8. During charging the cam roll-

ers and shoes are riding down the cam

lobes as the rotor rotates. The poppet valve

is open and fuel at transfer pump pressure

is pushing the pumping plungers outward.

Even though filling ends shortly after the roll-

ers reach the base circle of the cam, the

solenoid is still un-energized and the pop-

pet valve is unseated. In pumps also in-

corporating charging ports, these ports are

in registry and are also supplying fuel at

transfer pump pressure to the pumping

chamber.

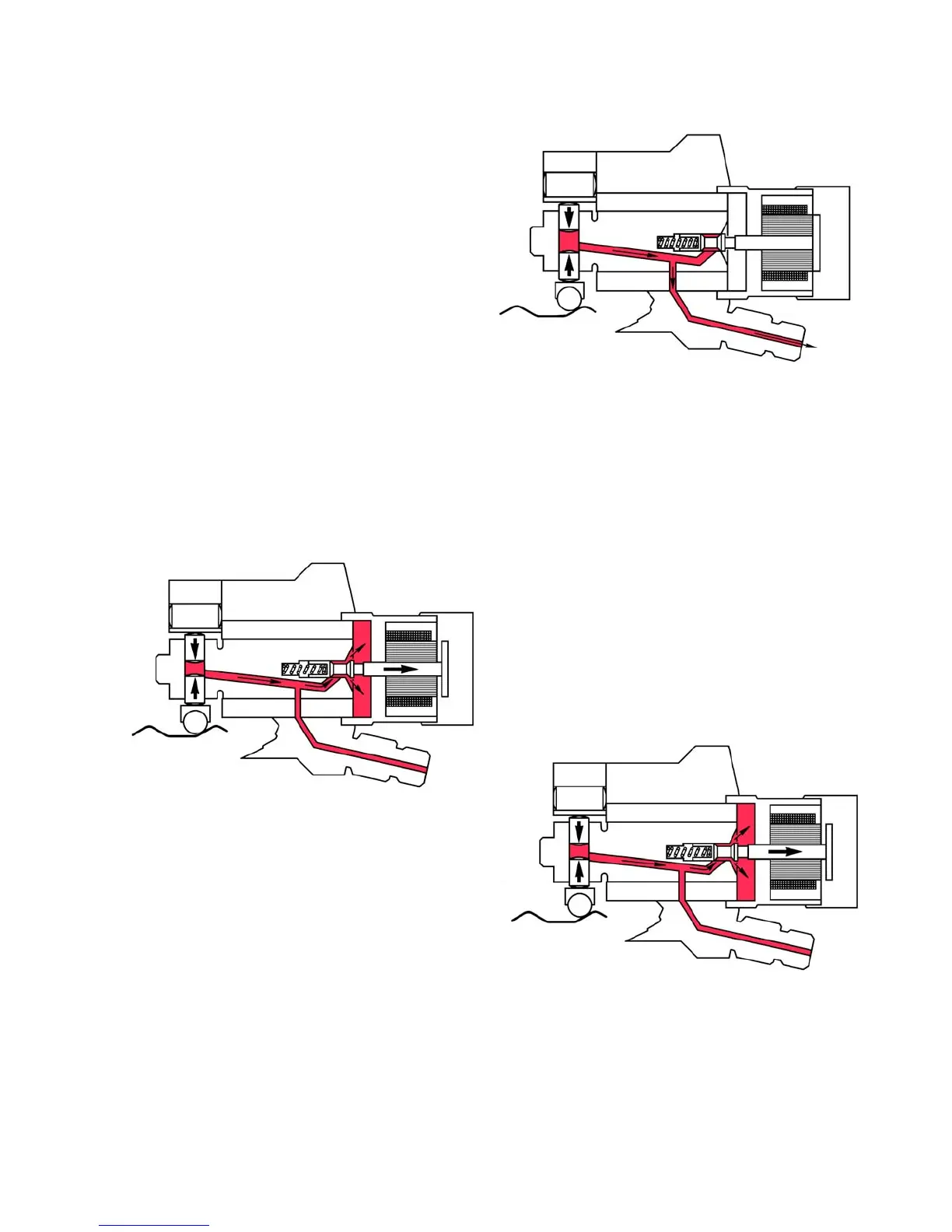

G. Discharging, Spill – Pump – Spill

(Figures 1.9, 1.10, and 1.11)

Further rotor rotation causes the discharge

port of the rotor to start to register with one

of the outlet drillings in the hydraulic head.

When the rollers start to ride up the cam

lobes, the plungers are simultaneously dis-

placed inward. Until current is switched on

to the fuel control solenoid, causing the

poppet valve to seat, displaced fuel is

spilled back into the transfer pump circuit.

As the rollers continue up the cam, the ECM

energizes the fuel solenoid, causing the

poppet valve to seat ending the initial Spill

portion of the discharge event. Fuel now at

injection pressure is forced out the dis-

charge port and drillings in the hydraulic

head, through the discharge fitting contain-

ing a snubber valve and on to the injection

nozzle. The Pump portion of the discharge

event ends when the ECM de-energizes

the fuel control solenoid allowing the pop-

pet valve to unseat and Spill the remain-

der of the displaced fuel back into the trans-

fer pump circuit . The high-pressure accu-

mulator absorbs the resultant pressure

spike from this spill event.

Fig. 1.10

7

H. Snubber Plates

Each DE discharge fitting contains a

snubber plate assembly. The orifice plates

are held on their seats by a light spring.

Spill

Fig. 1.9

Power Off

Valve Open

Power Off

Valve Open

Fig. 1.11

Spill

Power On

Valve Closed

Pump

Loading...

Loading...