MANIFOLD

ABSOLUTE

PRESSURE

ENGINE

COOLANT

TEMPERATURE

CRANKSHAFT

REFERENCE

(1 PULSE/CYL)

ELECTRONIC

CONTROL

UNIT

INJECT

PULSE

Return Fuel Temperature

MANIFOLD

ABSOLUTE

PRESSURE

ENGINE

COOLANT

TEMPERATURE

CRANKSHAFT

REFERENCE

(1 PULSE/CYL)

MANIFOLD

ABSOLUTE

PRESSURE

ENGINE

COOLANT

TEMPERATURE

CRANKSHAFT

REFERENCE

(1 PULSE/CYL)

ELECTRONIC

CONTROL

UNIT

INJECT

PULSE

ELECTRONIC

CONTROL

UNIT

INJECT

PULSE

Return Fuel Temperature

mains open during the charging phase of the

pump sequence

The DE hydraulic head assembly contains the

bore in which the rotor revolves, and the charg-

ing and discharge ports, a high-pressure ac-

cumulator to absorb the pressure spikes from

the fuel spilling event and a

low-pressure accumulator to

assist with rotor charging at

high speeds. The head also in-

corporates discharge fittings

each of which contains a snub-

ber plate, snubber seat, snub-

ber spring and retaining screw.

The snubber plates are de-

signed to control the injection

pressure following and between

each injection to prevent sec-

ondary injections or other unde-

sirable injection line pressure

characteristics.

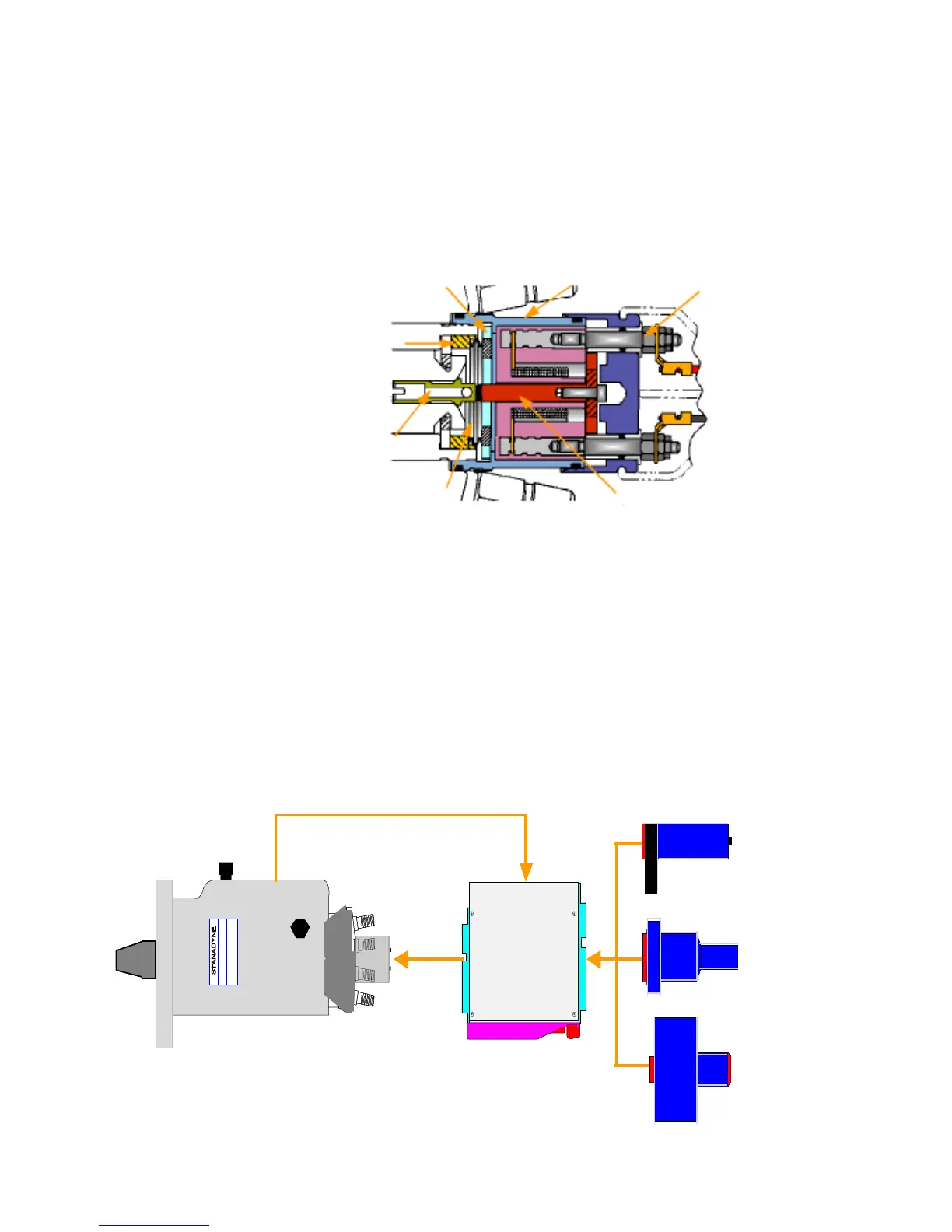

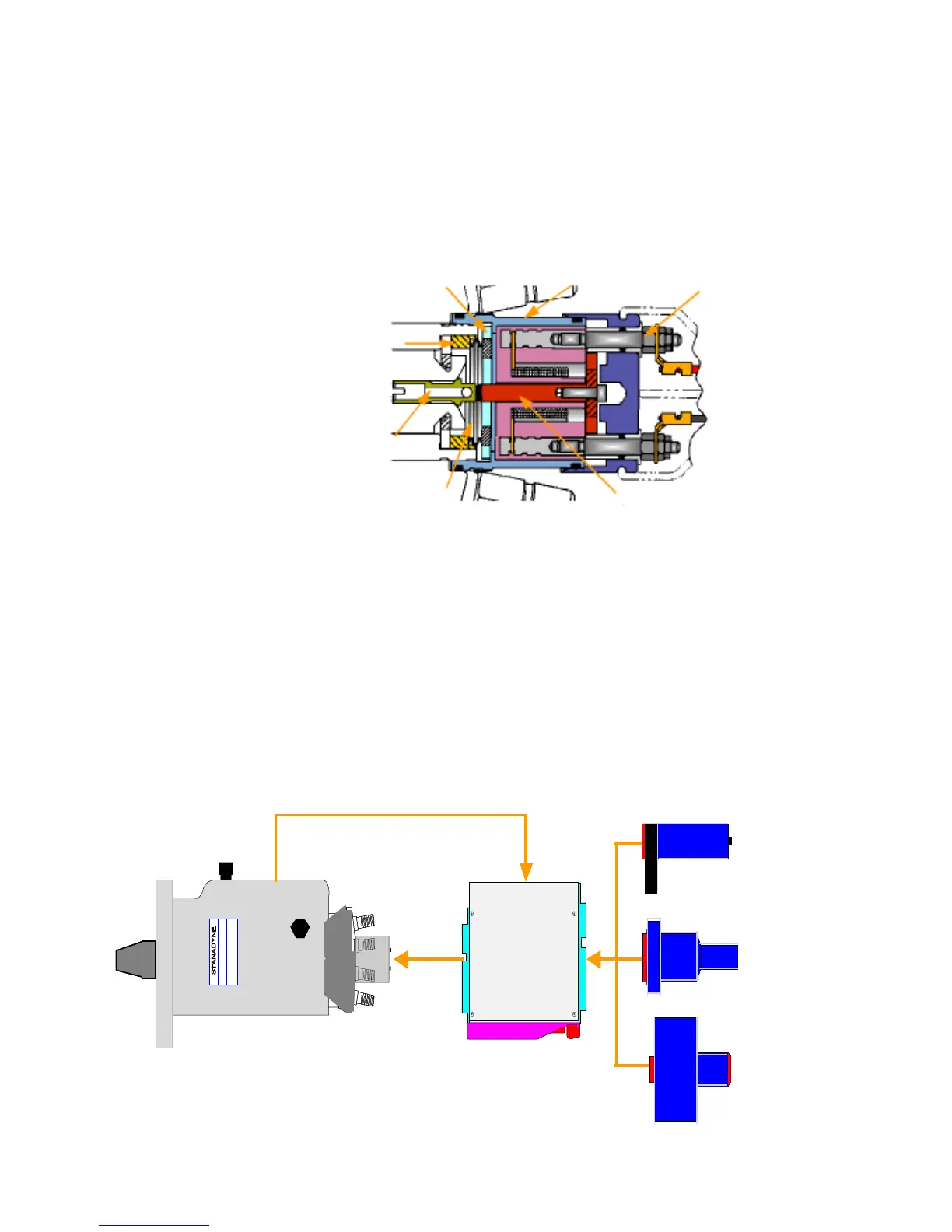

B. Electrical Circuitry (Figure 1.2 and 1.3)

The DE pump only incorporates one sensor, a

thermistor that provides the Engine Control

Module (ECM) with fuel temperature data.

The OEM’s equipment ECM switches current

DE-10

Pump

Fig. 1.2

to the pump solenoid on and off. On the early

part of the pumping cam ramp the solenoid, in

most situations, will remain un-energized allow-

ing the plunger displaced volume to be spilled.

At a precise moment in the discharge se-

quence the ECM energizes the solenoid mov-

ing the armature pin in contact with the rotor

mounted poppet valve causing the valve to seat

and seal. When the poppet valve seals, injec-

tion pumping commences. When the ECM pro-

gram determines that the engine has received

the correct amount of fuel, the current to the

solenoid is interrupted allowing the poppet valve

to unseat spilling the remainder of the fuel

charge. Hence the DE pump has a spill-pump-

spill fueling strategy.

Engine Control

Module

1

2

3

4

5

6

7

1. Armature Pin

2. Poppet Valve

3. Solenoid Terminal (2)

4. Solenoid Assy.

5. Armature Cover

Retainer

6. Adjustable Spacer

Retainer

7. Adjustable Spacer

(Crush Washer)

Fig 1.3

2

Return Fuel Temperature

Crankshaft

Reference (1

pulse/CYL)

Engine

Coolant

Temperature

Manifold

Absolute

Pressure

Inject

Pulse

Loading...

Loading...