(when measured in time) remains con-

stant over the full range of engine speeds.

Because injection lag is a constant, as

the engine turns faster, the injection event

will become progressively more retarded

if pump to engine timing is not ad-

vanced.

On most D-Series pumps a hydro-me-

chanical mechanism is typically used to

rotate the cam ring against the direction

of rotation to compensate for this inher-

ent injection lag.

With the DE pump models however, both

timing and delivered fuel quantity can be

controlled with adjustments of the Spill-

Pump-Spill events. Rotation of the cam

ring is not necessary and with it the need

for complex advance mechanisms.

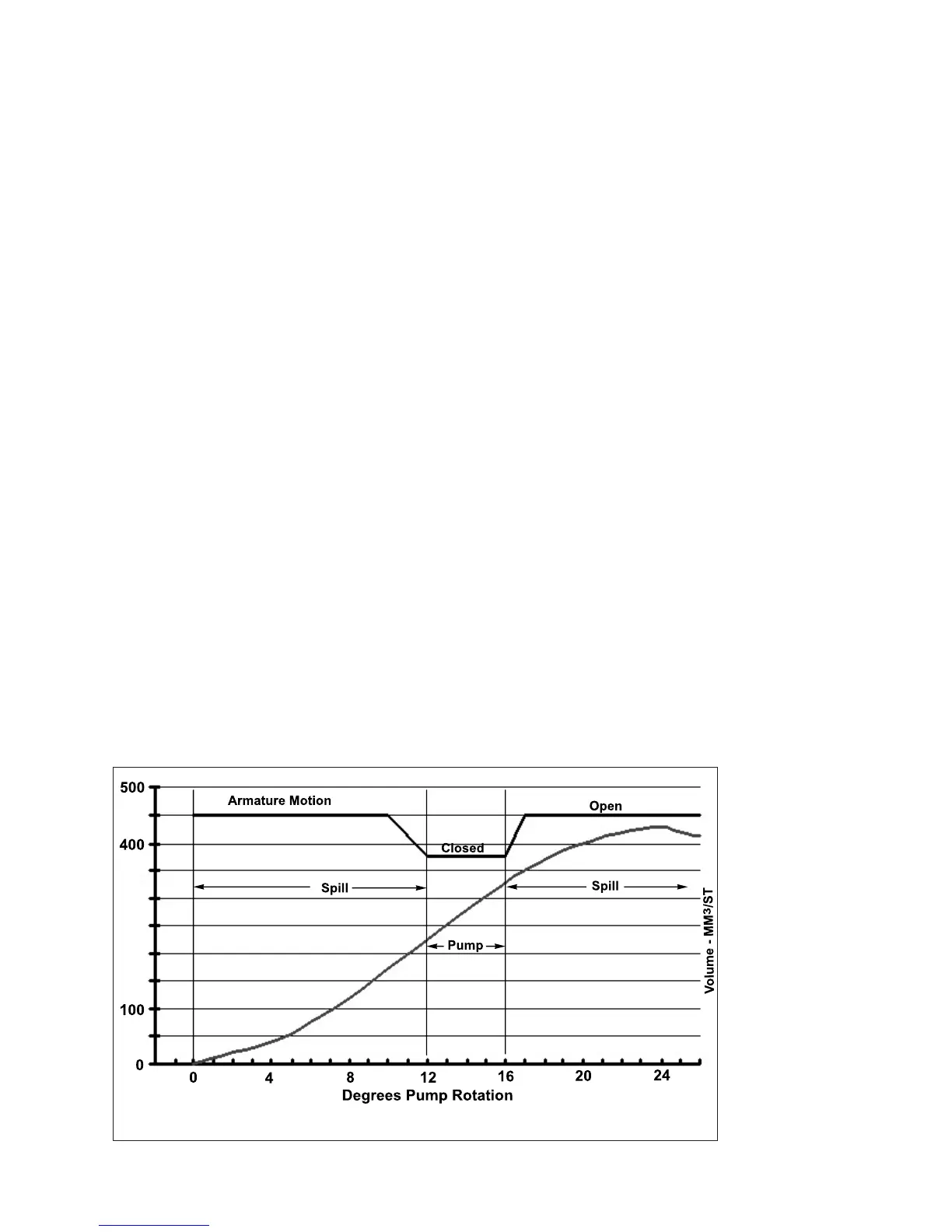

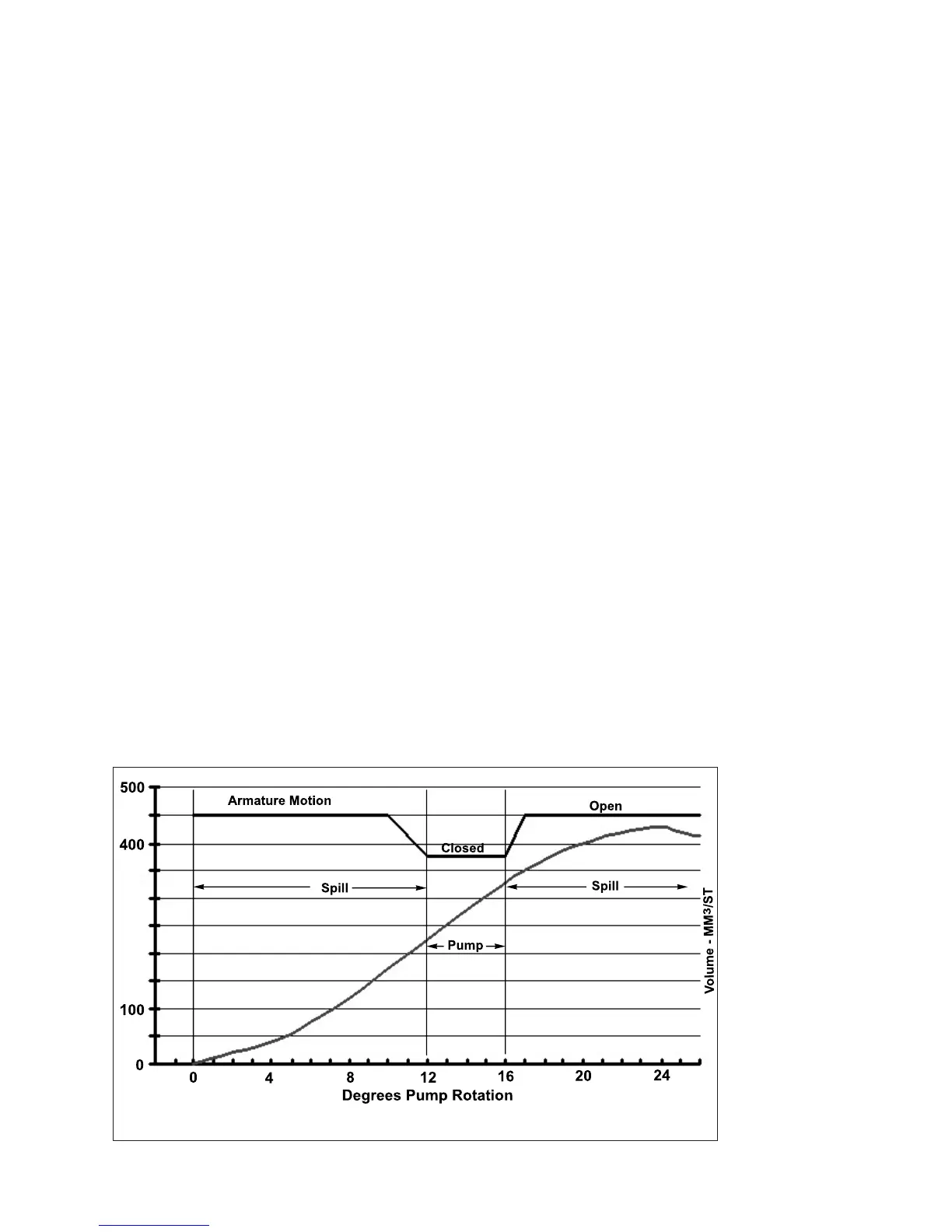

Shown in Figure 1.13 is a hypothetical

cam ring ramp. At 0 degrees of pump

rotation, the ramp of the cam starts to

rise (Line of Symmetry , LOS). From 7

degrees to 18 degrees from the Line of

Symmetry the rise of the cam ramp re-

mains constant creating a constant rate

of delivery (20 mm

3

per degree of pump

rotation in this example). As shown the

pumping event starts at 12 degrees of

pump rotation (Line of Symmetry Start of

Pumping, LOSSOP). At 16 degrees the

second spill event starts, ending the pump-

ing event that lasted a total of 4 degrees

delivering a total of 80 mm

3

of fuel. With an

increase in engine speed, to compensate

for injection lag, pump timing needs to be

advanced. Without a means of rotating the

cam, advancing the injection event is ac-

complished by simply starting the pump-

ing event earlier. For example, instead of

starting at 12 degrees it now starts at 10

degrees. Now the injection pump is start-

ing the pumping event 2 pump degrees (4

engine degrees) earlier. If the engine de-

mand for fuel quantity has remained the

same, in this example 80mm

3

, the start of

the second spill event needs to start 2 pump

degrees earlier to maintain the 4 degree

pumping event. Also note that fuel quantity

can be increased or decreased by short-

ening or lenghtening the duration of the

pumping event.

The OEM’s ECM controls pumping and

spill event timing. The only parameters that

the pump communicates to the ECM are

return fuel temperature and a current inflec-

tion caused by

the solenoid

armature

reaching the

end of its

travel. Pump

to engine po-

sitional rela-

tionship in DE

applications

are fixed and

since the cam

is fixed to the

pump housing,

the engine to

cam relation-

9

Fig. 1.13

Loading...

Loading...