SECTION 1 - CONSTRUCTION AND

OPERATION

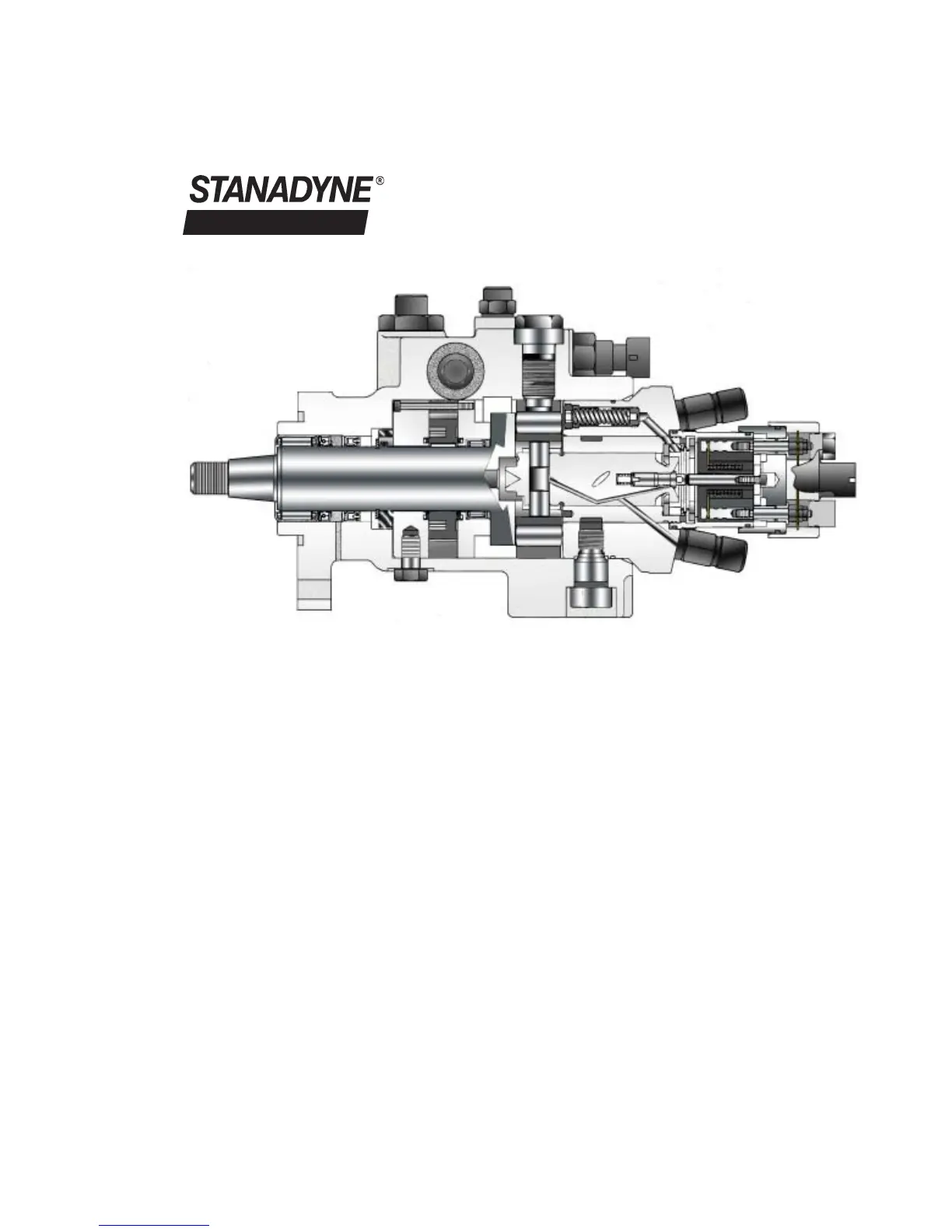

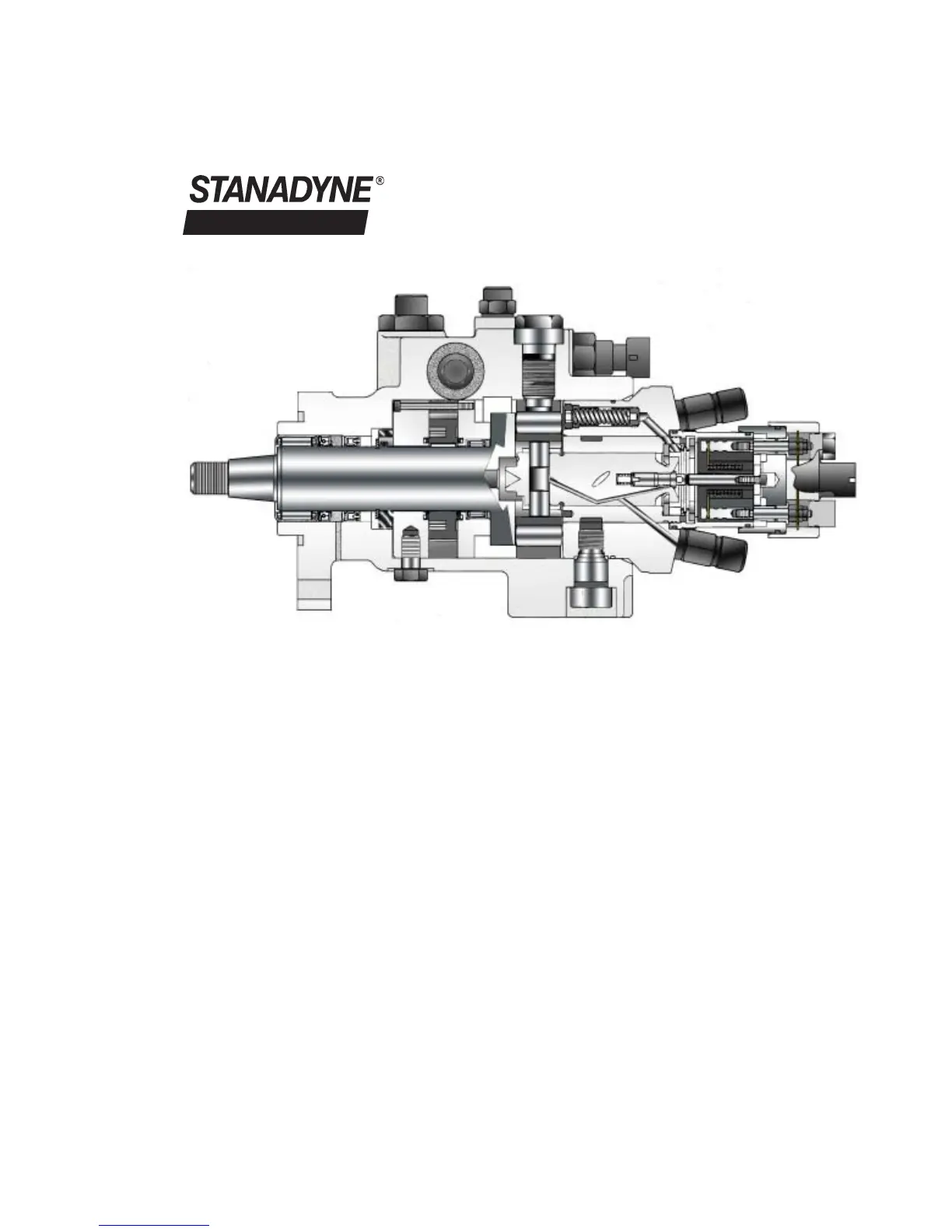

Model DE Electronic

Fuel Injection Pump

A. Components and Functions (Figure

1.1)

The main components of the DE pump are

pictured above in Figure 1.1. They include:

1. Fuel Inlet Fitting

2. Return Line Connector/Housing

Pressure Regulator

3. Heavy Duty Drive Shaft

4. Transfer Pump

5. Cam Ring

6. Distributor Rotor

7. Poppet Valve

8. Fuel Control Solenoid

9. Discharge Fittings with Snubber

Components

I

The main rotating components are the drive

shaft, the cam roller shoes and cam rollers,

transfer pump blades and their retainer, and the

distributor rotor and poppet valve.

In the DE pump Shown in Figure 1.1, the drive

shaft is supported at both ends by needle bear-

ings and carries the two cam roller shoes and

cam rollers. It also incorporates a slot, which

engages with a tang on the distributor rotor to

drive the latter. As the drive shaft is rotated, in-

ternal lobes on the cam ring drive the cam roll-

ers and shoes inward, simultaneously displac-

ing the two opposed pumping plungers carried

in the rotor. The number of cam lobes equals

the number of engine cylinders being served.

1.

2.

3 .

4.

5.

6.

7.

8.

9.

The distributor rotor in the 4-cylinder design of

the DE pump incorporates no charging ports

whereas the six cylinder design incorporates

one. Both designs incorporate one discharge

port. In the four-cylinder pump all charging fuel

must pass around the poppet valve that re-

Fig. 1.1

1

Loading...

Loading...