the transfer pump group, cam ring and head and

rotor assembly fit for erosion, wear or cracks.

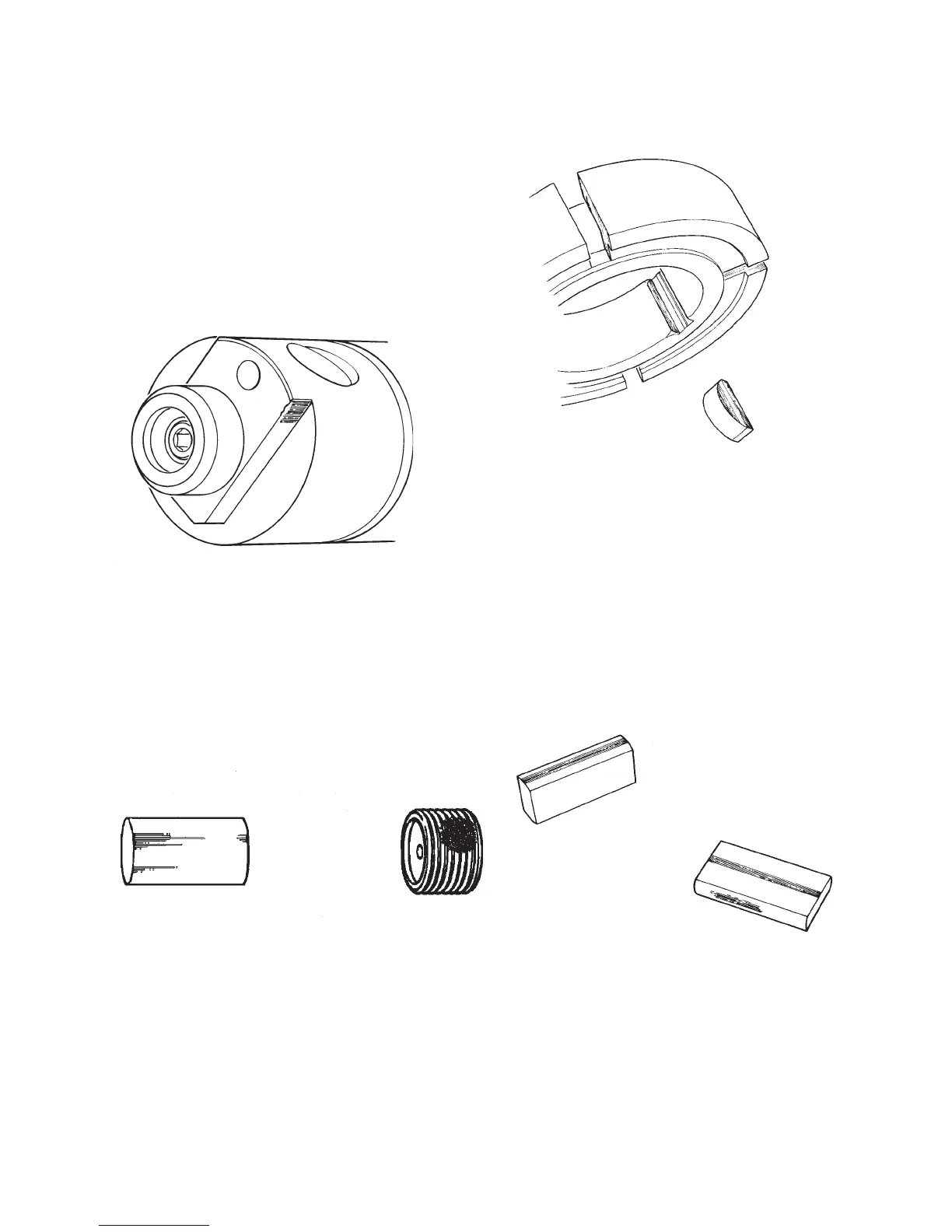

2. Distributor Rotor (Fig. 3.1) – Examine the

shank of the rotor for wear or erosion around

the discharge port area. Examine the poppet

valve seat for cracking or erosion. The drive

tang area may show polishing or wear in the

corners which contact the drive shaft as illus-

trated but this is considered normal.

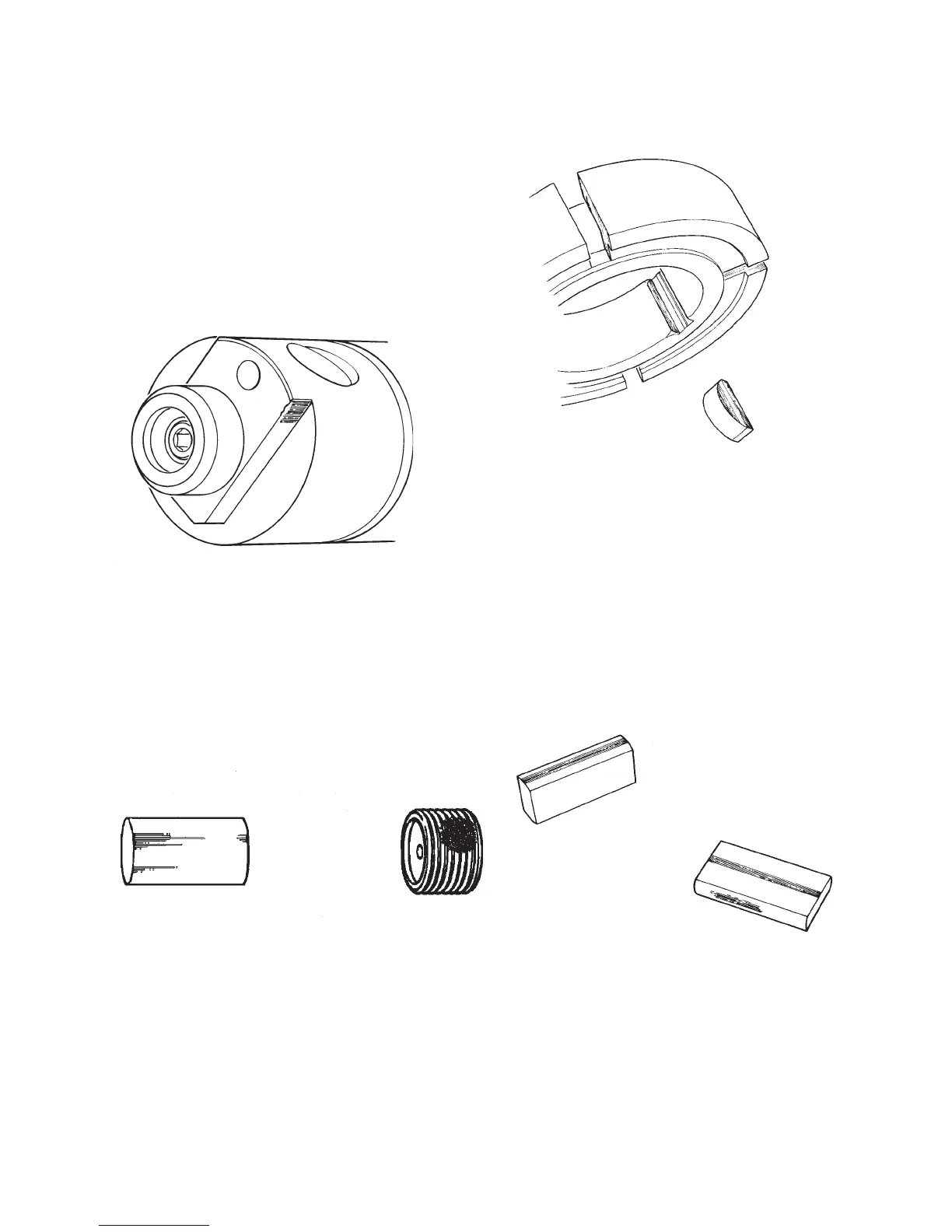

3. Transfer Pump Regulator Piston and Ad-

justing Screw (Fig. 3.2) – Light scratches on

the regulating pistons are considered normal.

Examine the adjusting screw for adequate

thread retention compound and for tightness

of the orifice plate in the screw. Be sure that

the orifice is not plugged with foreign material.

4. Transfer Pump Blade Retainer and Drive

Key (Fig. 3.3) – Inspect the blade slots for scor-

ing, burring or excessive wear. Check to see if

oversize blades can be used. Examine the drive

key for damage and replace as necessary.

5. Transfer Pump Blades (Fig. 3.4) - Exam-

ine the blades for wear on the rounded ends

caused by contact with the liner or blade spring.

Also inspect the blades for wear caused by

contact with blade retainer. It is recommended

that used blades be reinstalled in the same ori-

entation that they were originally installed, that

is with the same surface contacting the liner.

Orientation of new blades is unimportant.

26

Fig. 3.1

Fig.3.2

Fig. 3.3

Fig. 3.4

Loading...

Loading...