6

screen where it acts on the end of the

regulating piston. The pressure over-

comes the spring force on the piston

and moves the piston in its bore un-

covering the regulating slot in the

sleeve. Fuel flowing through the regu-

lating slot joins the fuel entering the

pump and is recirculated. As pump

speed increases, transfer pump out-

put increases causing transfer pump

pressure to increase.

The transfer pump regulator plug as-

sembly (adjusting plug assembly)

provides a means of changing the

spring preload which adjusts trans-

fer pump pressure.

A sectionally thin, sharp edge orifice, lo-

cated in the transfer pump regulator plug

assembly provides the DE2 with a viscos-

ity compensation feature. Flow through this

orifice is unaffected by changes in viscos-

ity. With hot and/or low viscosity fuels, leak-

age past the regulating piston and bore

clearances increases causing fuel pressure

in the spring cavity to increase , since flow

through the orifice remains essentially the

same regardless of fuel viscosity. This in-

creased fuel pressure serves to assist the

regulator spring in resisting movement of

the piston, this uncovering less of the regu-

lator slot, when fuels are lower in viscosity.

This in turn causes an increase of transfer

pressure to offset the increased leakage

throughout the pump when fuel viscosity is

less then ideal.

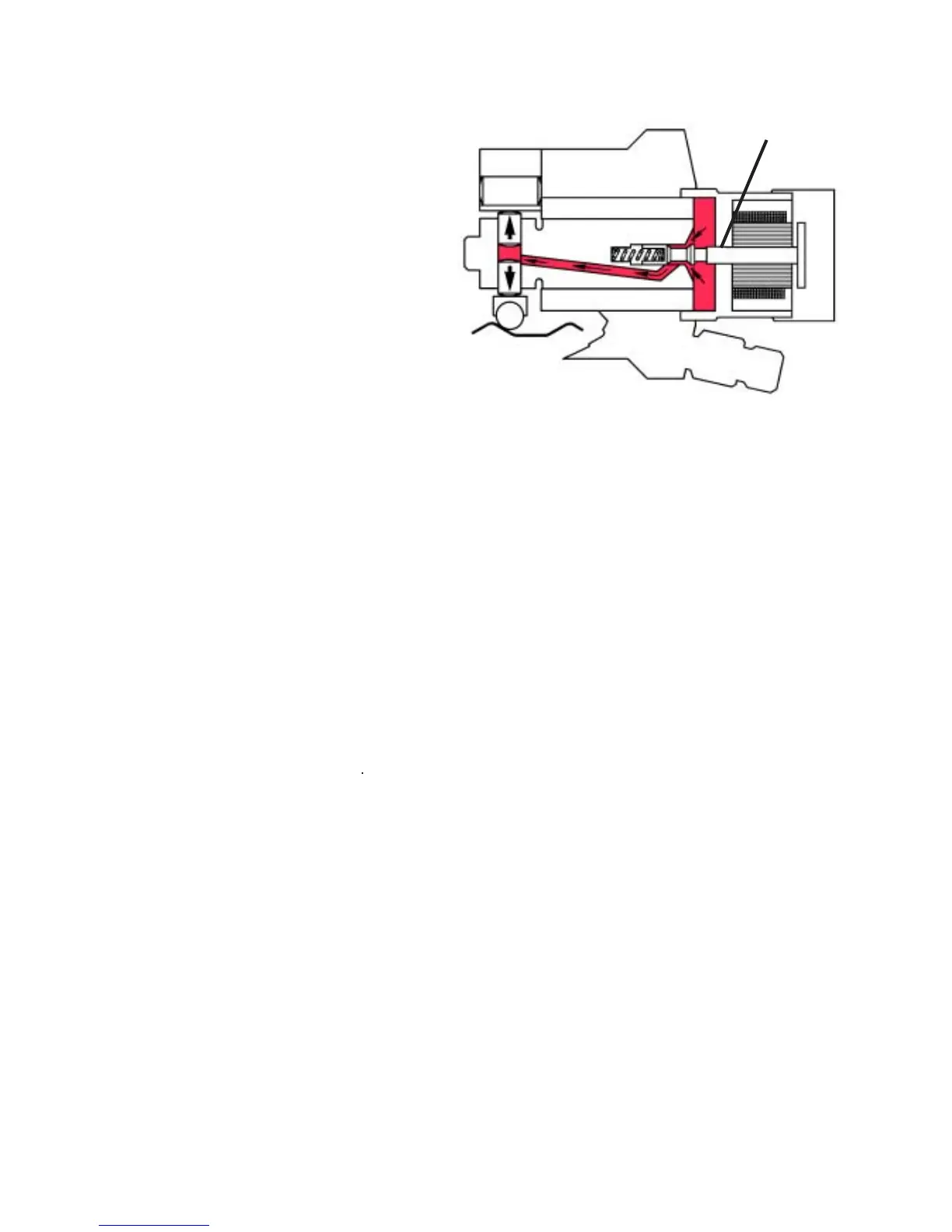

F. Charging (Figure 1.8, 1.9, 1.10 and

1.11)

As the drive shaft and rotor rotate, fuel un-

der transfer pump pressure flows out of the

transfer pump porting plate, through the

porting plate screw, down a passage in the

housing and into the head locking screw.

Cam

Roller

Armature Plate

Assy.

Fig. 1.8

From the head locking screw this fuel then

flows through two drillings in the hydraulic

head and fills the area around the poppet

valve and the fuel control solenoid arma-

ture. This fuel flows past the open poppet

valve, down through the rotor into the pump-

ing chamber filling the volume between the

two pumping plungers, which are then

forced outward.

On the six cylinder application, fuel from

the head locking screw is also directed to

a charging annulus in the hydraulic head

and feeds charging ports in the sleeve. As

the rotor revolves, an inlet passage in the

rotor registers with one of the charging

annulus ports allowing additional fuel to as-

sist in charging the plungers. With further

rotor rotation this charging port goes out

of registry within the hydraulic head trap-

ping the fuel charge in the pumping cham-

ber.

With the DE pump the pumping chamber

is filled completely between each injection

regardless of the quantity of fuel to be in-

jected into the engine. This differs greatly

from previous inlet metered D series

pumps where charging quantities were

metered based on the amount of metering

valve opening.

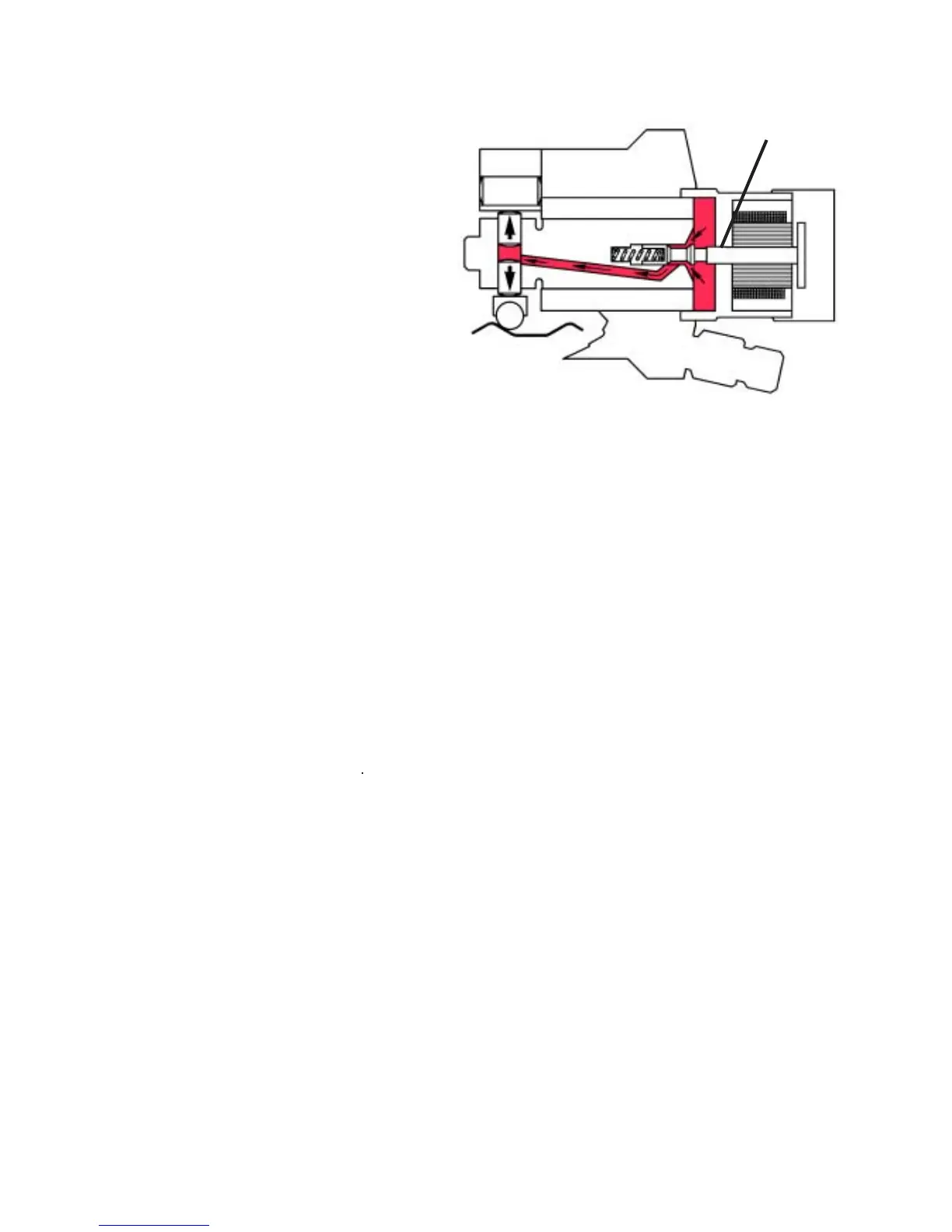

Power

Off

Valve

Open

Loading...

Loading...