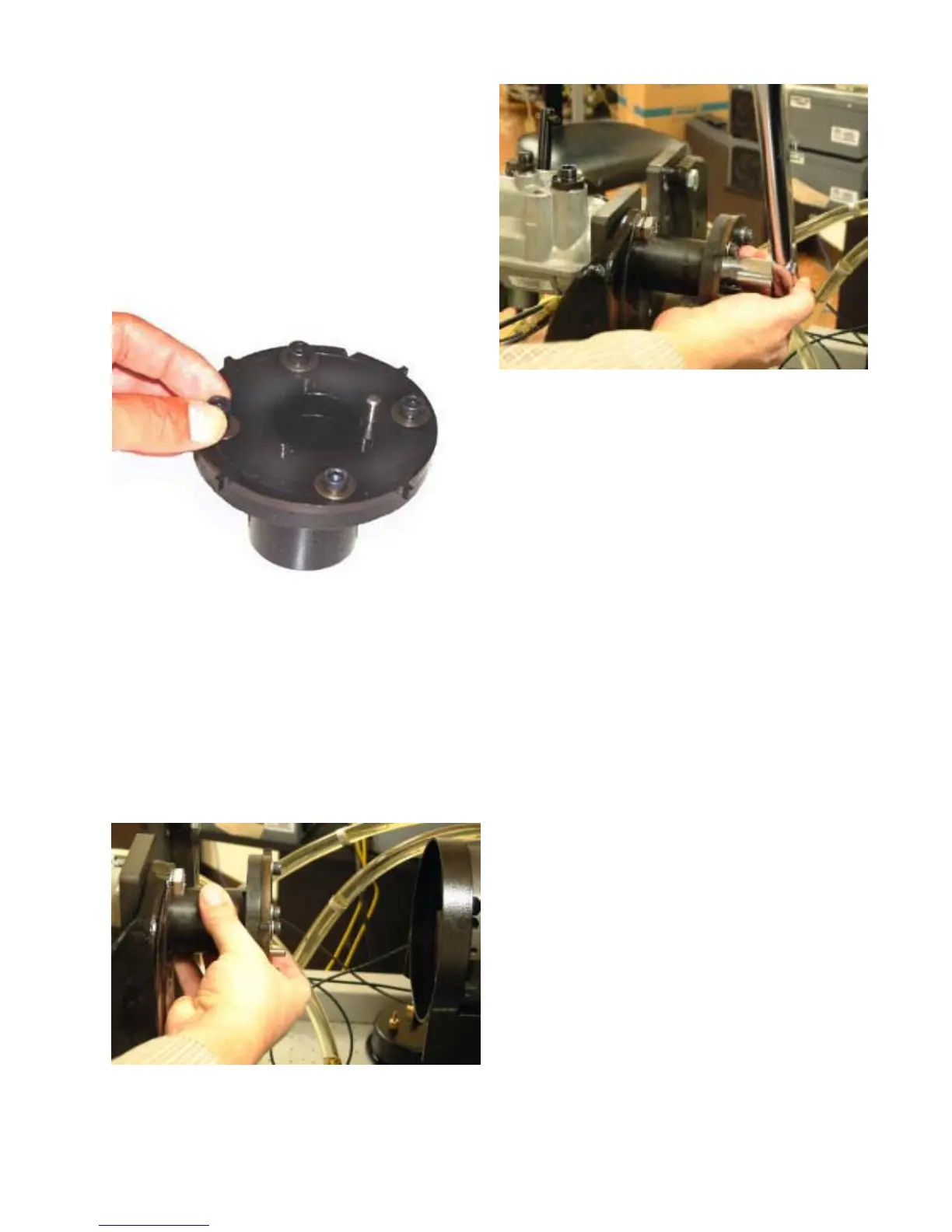

Step 3. Place the appropriate toothed wheel

on the Drive Adaptor. Note that these wheels

are marked “pump side” and “bench side”. The

“pump side” marking must be placed against

the drive adapter. (towards the pump when

the adapter is installed on the pump). Install

the four 8mm socket head cap screws and

washers finger tight. Ref. Figures 5.2 and 5.3.

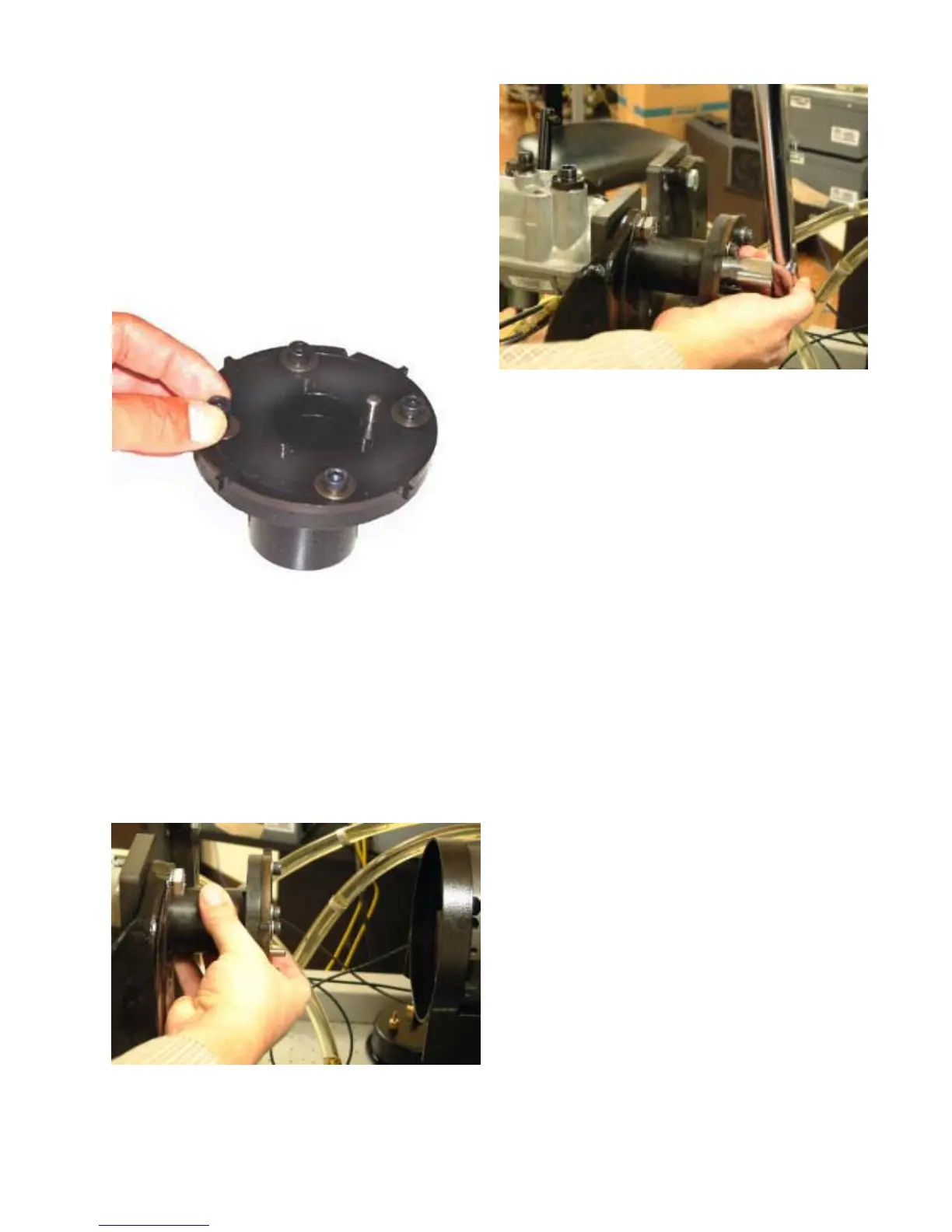

Step 4. Install the drive adaptor assembly onto

the pump drive shaft. Install the washer and 24

mm nut onto the drive shaft finger tight Ref.

Figure 5.4.

Step 5. Mount the test bench mounting plate

and pump to the test bench pedestal per the

manufacturers recommended

procedure.Tighten the drive shaft retaining nut

to 140-150 ft-lbs. (190-200 N•m) with the tim-

ing pin installed (prevents the drive shaft from

rotating while tightening). Ref. Figure 5.5.

Step 6. Using a suitable 6.2/6.5L test bench

drive adaptor, align the pin and holes with the

DE pump drive adaptor. Install the mounting

bolts and tighten to the test bench manufac-

turers recommended torque value.

Step 7. Loosen the two upper flange bolts.

Remove the right side bolt (viewed from the

fuel control solenoid end), but leave the left

side bolt with a few threads of engagement.

NOTE: Due to the housing configuration, it

may be necessary to use a slightly shorter

mounting bolt in the left side flange hole.

Step 8. Assemble the 36263 Hall Effect

Bracket Assembly. Orientate the hall effect

sensor over the toothed wheel. With the

right side bracket mounting hole aligned with

right side pump flange mounting hole, insert

a pump mounting bolt and tighten finger

tight. Ref. Figure 5.6.

47

Fig. 5.3

Fig. 5.4

Fig. 5.5

Loading...

Loading...