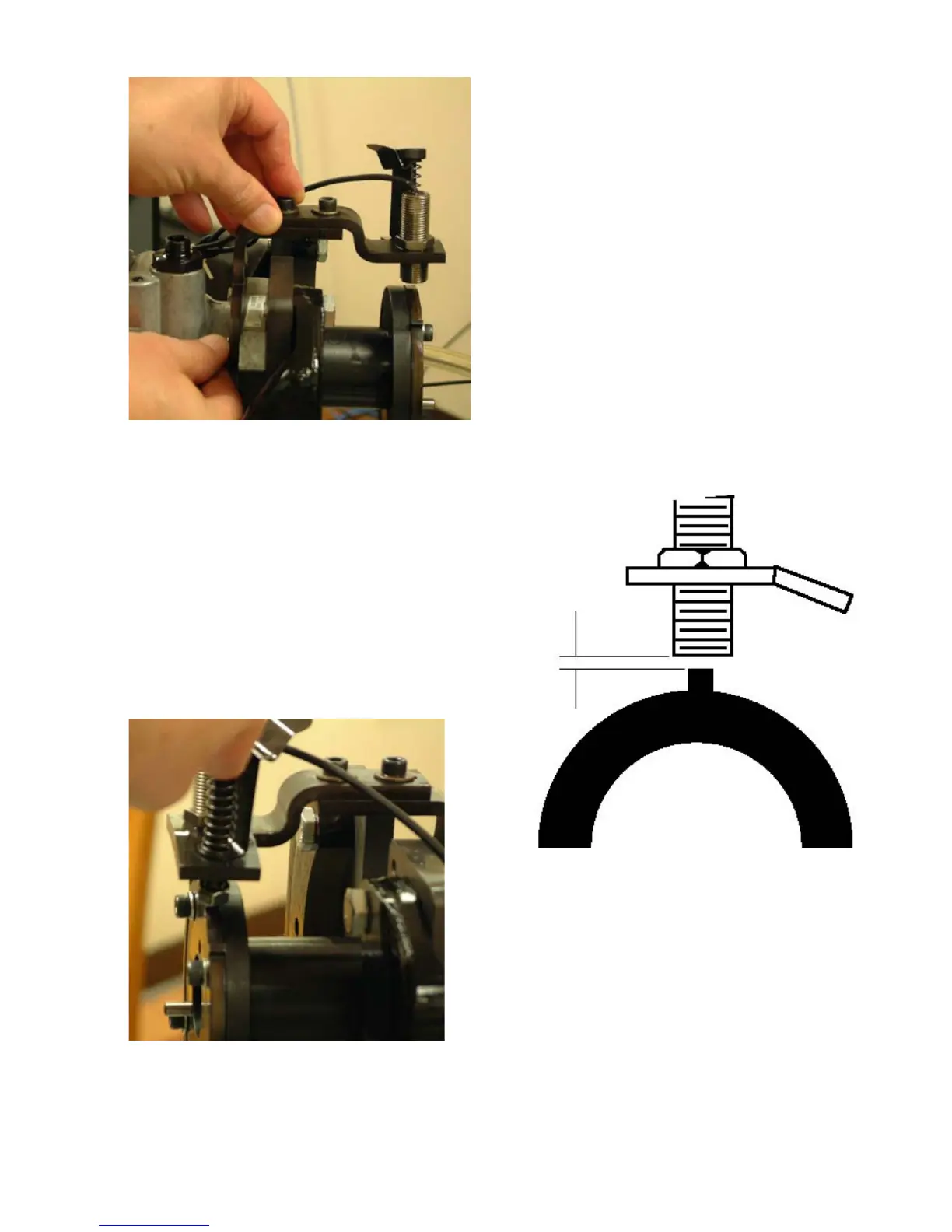

Step 9. Rotate the Hall Effect Sensor Bracket

to engage the left side mounting bolt. Tighten

both flange mounting bolts according to the test

bench manufacturers procedures.

Step 10. Using the spring loaded timing spike

on the Hall effect sensor bracket, accurately

locate the correct rotational position of the

toothed wheel. Tighten the four 8 mm socket

screws to 20-30 lbf-in (2-3 N•m). Ref. Figure

5.7.

Step 11. Remove the timing pin and install the

36464 Housing Pressure tap. Connect the hous-

ing pressure gage supply line to the 36464

Housing Pressure Tap.

Step 12. Loosen the two positioning screws

on the top of the sensor bracket. Adjust the

Hall effect sensor, placing the center of the

sensor in line over the center of the toothed

wheel. Tighten the positioning screws to 20-30

lbf-in (2-3 N•m).

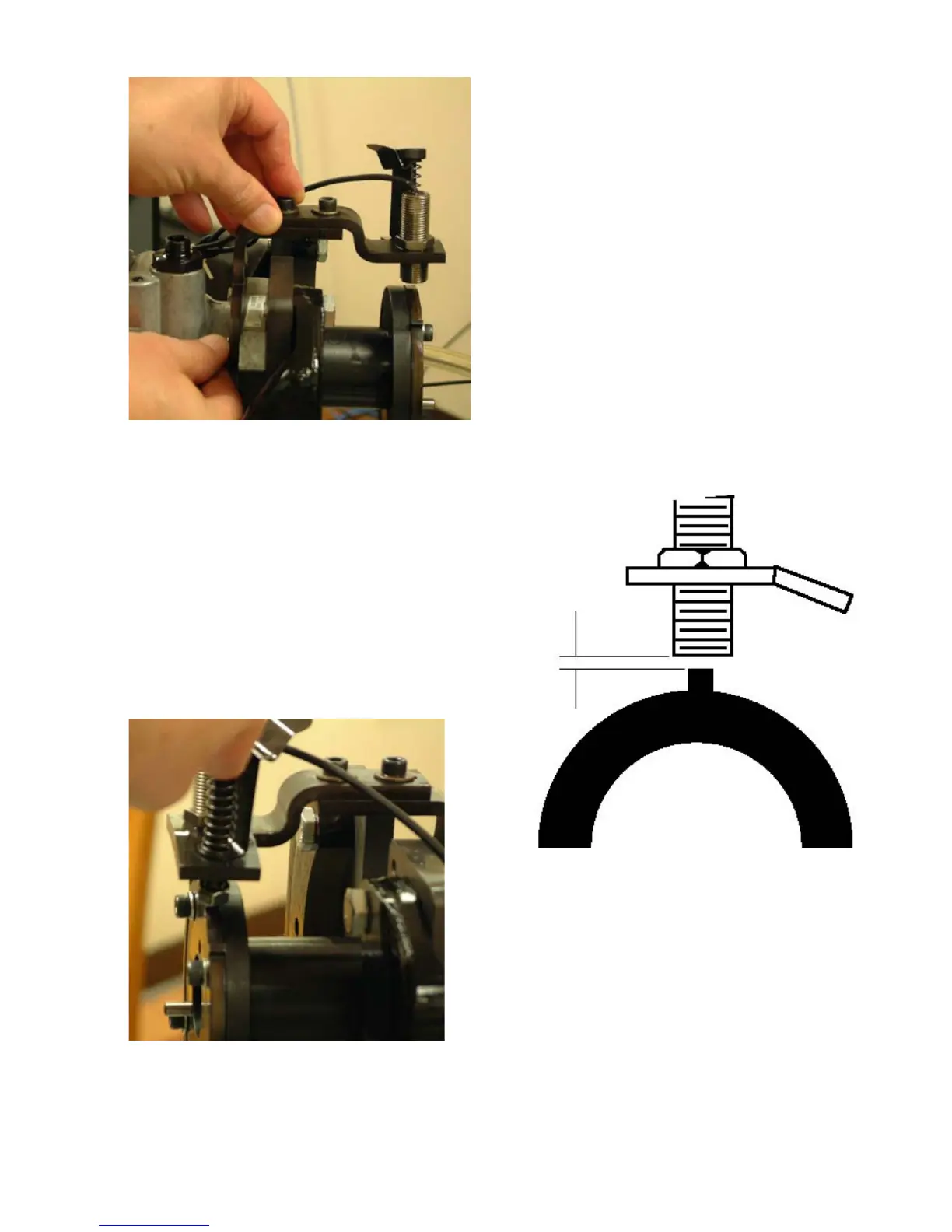

Step 13. Loosen the Hall effect sensor locknut

and adjust the sensor to achieve an air gap of

.100 inch (± .020 inch) {2.5 mm (±.40 mm)}

between the sensor and one of the teeth on

the toothed wheel. Hold the Hall effect sensor

while tightening the locknut to 20-30 lbf-in (2-3

N•m). Ref. Figure 5.8.

Step 14. Remove the plug in the head locking

screw and install the 33497 Transfer Pump

Pressure Tap. Connect the transfer pump pres-

sure gage line with a shut-off valve to the Trans-

fer Pump Pressure Tap.

Step 15. Install the 36274 Inlet and Return Fit-

ting Assembly on the pump. Tighten the tube

48

Fig. 5.7

Fig. 5.8

Fig. 5.6

2.5mm (± .4 mm)

.100 in. (±.020 in.)

Hall Effect

Sensor

Tooth Wheel

Loading...

Loading...