Pubn No: 30000H0K

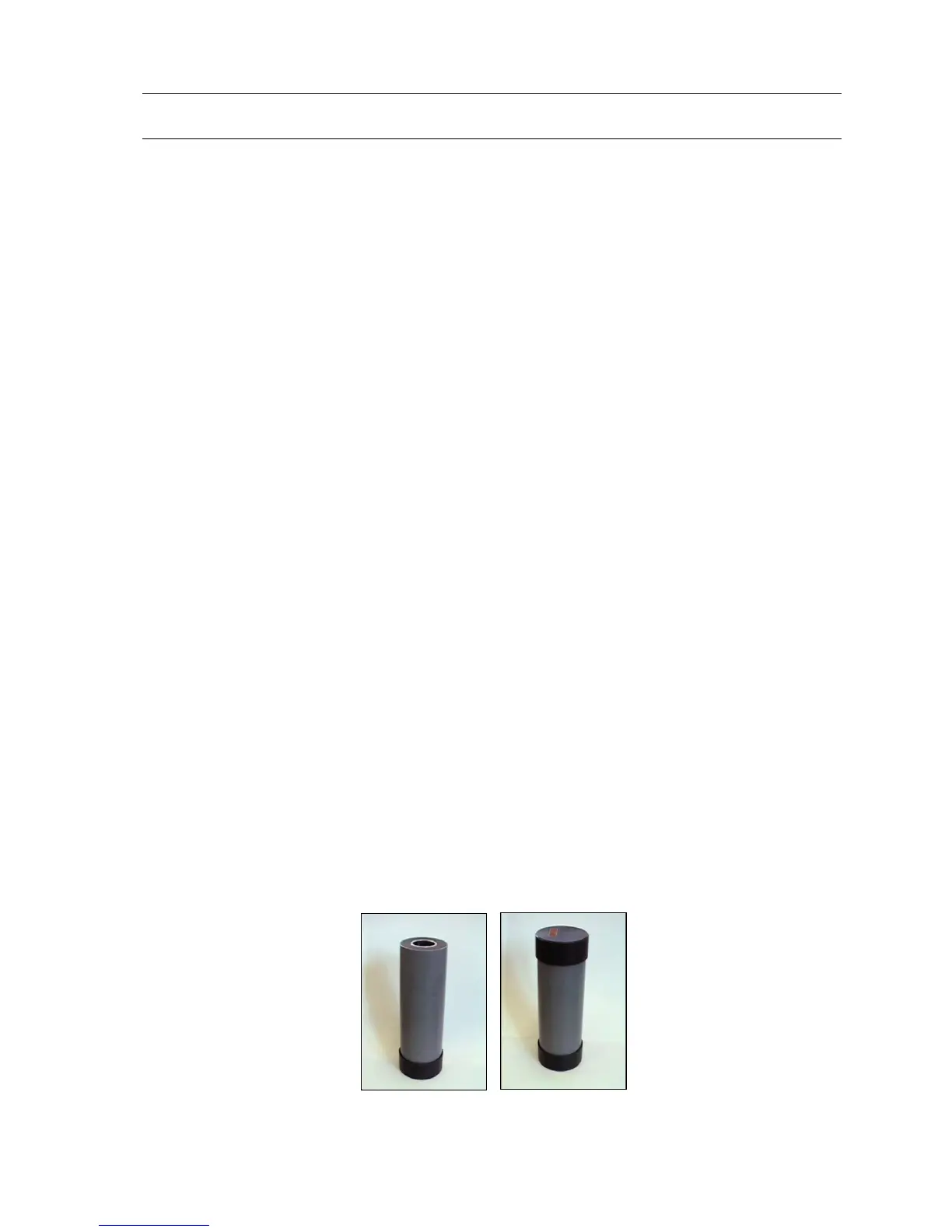

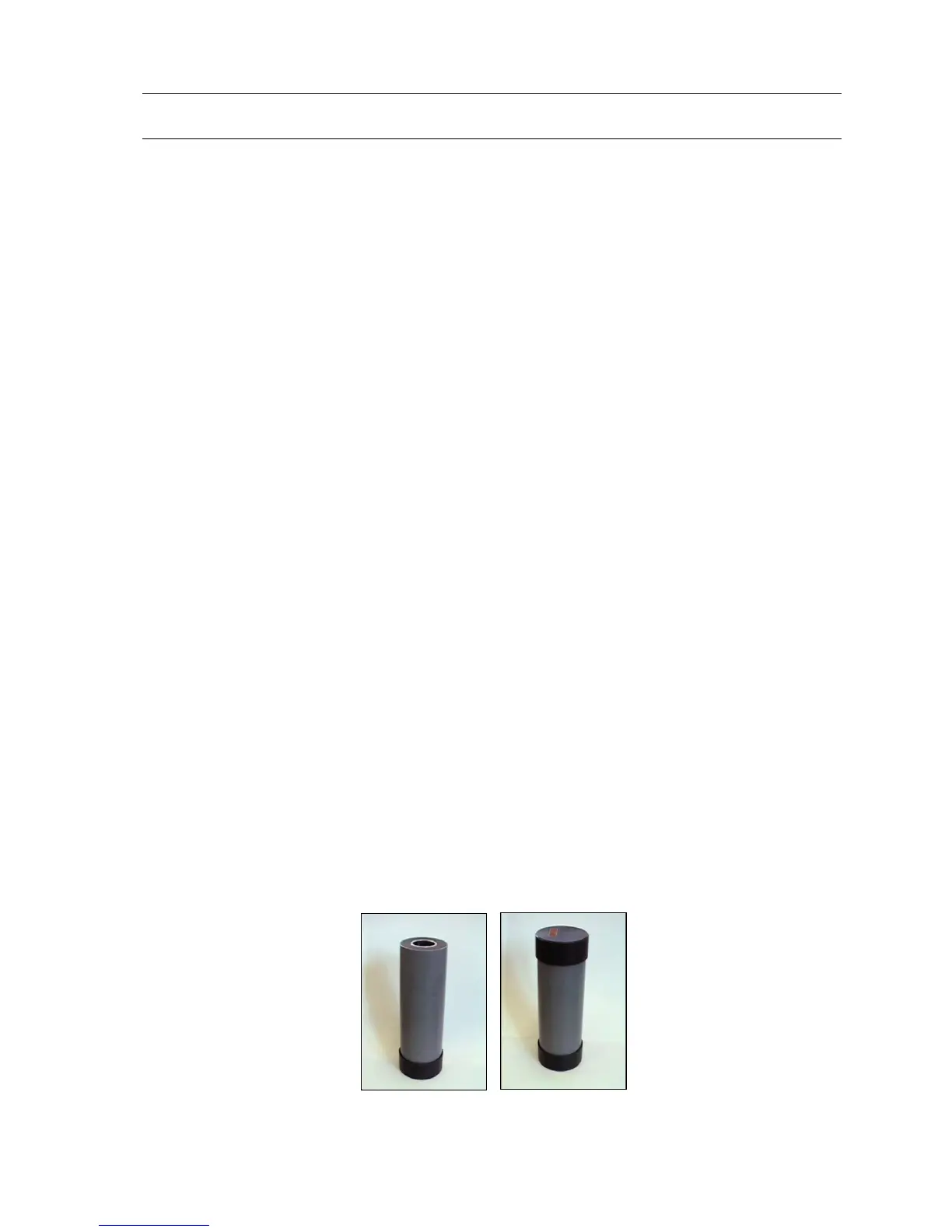

APPENDIX A: SETA COOLANT MODULE 13870-0

The coolant module is used to reduce the temperature of the sample cup to below ambient temperature for

samples with low flash points, before starting a test. To use the coolant module, proceed as follows (refer

to the illustrations):

WARNING: ALWAYS WEAR SAFETY GLASSES AND GLOVES WHEN HANDLING DRY ICE (SOLID

CO2) OR ISOPROPYL ALCOHOL. SERIOUS INJURY CAN RESULT FROM SPLASHES

REACHING THE EYES AND CONTACT WITH DRY ICE CAN CAUSE PAINFUL BURNS.

1) Cool the sample injection syringe and sample to at least 10°C below the target temperature.

2) Switch on the instrument and set the test temperature to 0.0°C.

3) Allow the cup to reach approximately ambient temperature.

4) Remove the top from the module.

5) Fill the cylinder to between a half and two thirds full of isopropyl alcohol.

6) Pulverise some dry ice (either with a grinder or by crushing in a cloth with a mallet) and slowly add

to the cylinder with a scoop or tongs. Initially the dry ice will evaporate almost immediately and

cause considerable foaming at the surface.

Note: An alternative mixture of crushed ice/water may be suitable depending on the expected

flash point (refer to Test Method).

7) Continue adding small quantities of dry ice and allow the foaming to subside after each addition.

8) When the ice begins to accumulate at the bottom of the cylinder start adding bigger pieces until the

liquid reaches approximately 25mm from the top of the cylinder.

9) Stir well to achieve even distribution.

10) Close the top cover to prevent evaporation loss and spillage.

11) Remove the base cap immediately prior to use.

12) Raise the lid and shutter assembly.

13) Insert the module base into the cup being careful not to damage or mark the cup.

14) Monitor the falling temperature. When this reaches at least 10°C below the required test

temperature remove the module, thoroughly dry the cup with paper tissue and close the lid.

15) Inject the prepared pre-cooled sample using the syringe

16) Light and adjust the pilot and test jets.

17) Monitor the rising temperature. When the temperature reaches the desired test temperature dip the

flame into the cup to carry out the flash/no flash test.

Note: It is recommended that extended use of the cooling module be interrupted for short

periods between tests, during which the temperature should be set to about 120°C to dry

off any condensation which may have occurred.

Issue K

10 Jun 2007

39

Loading...

Loading...