2

PRGPC Reset Auto

Raumtemp. 2

Raumtemp. 1

Warmwassertemp.

Zeit / Datum

Ferien / Partyprog.

Info Temperaturen

Heizkurven

Heizprogramme

Warmwasserprog.

Inbetriebnahme

1. Operating instructions for users and contractors

1.2 Equipment description

WPF is a heating system which is designed for

operation as brine/water heat pump. The heat

pump extracts energy from the heat source

medium i.e. brine at a low temperature level.

This extracted energy is then transferred to

the heating water at a higher level, enriched

with the energy transferred by the compressor.

Subject to the heat source temperature, the

heating water can be heated up to a flow tem-

perature of 60 °C.

Inside the WPF, a heating circuit pump and

a three-way valve have been integrated for

diverting the flow either to the heating circuit

or the DHW circuit. DHW is heated by pumping

the heating water, which has been heated by

the heat pump, through a heat exchanger into

the DHW cylinder, where it transfers its energy

to the DHW.

The equipment is regulated by an integral,

weather-compensated return temperature

controller (heat pump manager WPMiw(triple

phase) and WPMi(single phase).

The WPMi/WPMiw also regulates the DHW

heating to the required temperature. DHW

heating will be completed automatically by an

integral electric booster heater, if either the

high pressure sensor or the hot gas limiter of

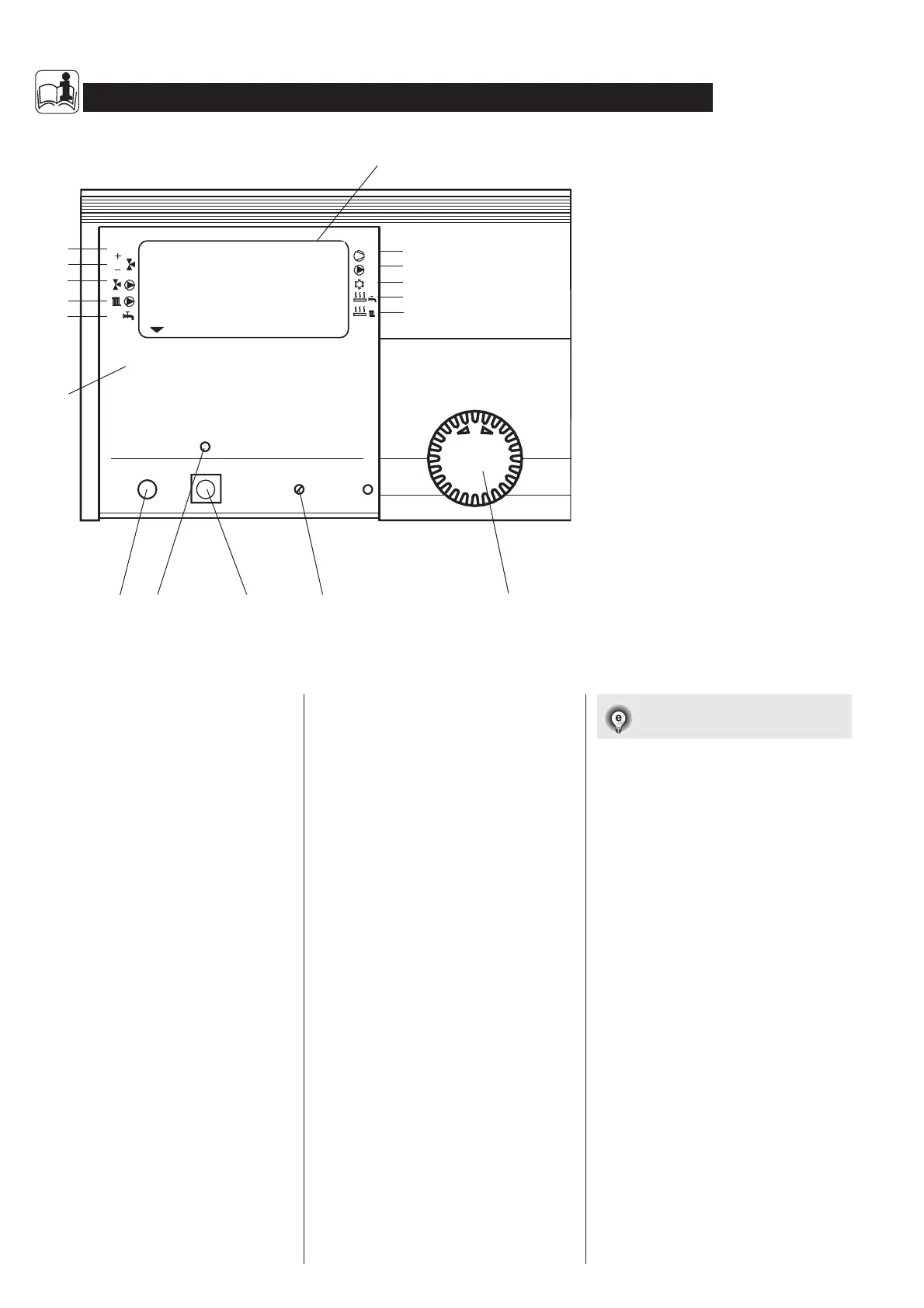

BCDEF

A

6

7

8

9

10

1

2

3

4

5

11

1.1 Equipment summary

the heat pump responds during DHW heating,

subject to the ECO function being enabled.

Subject to the ECO function being enabled, the

DHW heating will terminate and the set DHW

value overwritten with the actual DHW tempe-

rature that has been achieved.

Summary of available functions

z RS 232 interface for adjustment and

monitoring via PC

z System extension via FEK and FE 7 re-

mote control

z Input of system and heat pump frost pro-

tection limits

z The clock has a power backup for at least

24 hours

z Automatic kick-start pump control

z Reset option

z Stored error list with precise fault code

indication, together with date and time

display

z Rapid and accurate fault diagnostics

using system analysis including temper-

ature scan for heat pump and peripheral

equipment without additional equip-

ment.

z Factory settings for time switch programs

for all heating and DHW circuits

Roomtemp 1

Roomtemp 2

Temp DHW.

Day / Hour

Holiday / Partyprog.

Info temp

Heating curve

Heating prog.

Prog. Acqua San.

First Start-up

ROOM T HC 1

Anlagen-Statusanzeige

1 Mixer opens

2 Mixer closes

3 Circulation pump

heating circuit 2 "mixer circuit"

4 Circulation pump

heating circuit 1 "radiator circuit"

5 DHW heating

6 Compressor 1

7 Buffer cylinder loading pump

8 Cooling

Only for WPF with WPAC 1

9 Backup heating (DHW heating)

10 Backup heating (central heating)

11 Equipment menu

A Display

B Rotary selector

C Rotary selector Reset / Auto

D Programming key

E Programming indicator

F Optical interface RS 232

C26_03_01_0073

z

Heat pumps operate with particular econo-

my and environmental responsibility when

they work with a maximum flow tempera-

ture of 35 °C. Low flow temperatures can

be achieved by using area heating systems

(e.g. underfloor heating or wall heating

systems).

z

Size radiators so that the maximum re-

quired flow temperature does not exceed

45 °C.

z

Activating the control parameter „Pump

cycling“ can reduce the power drawn by

the circulation pump. In this connection,

refer to your local heating contractor.

z

When activating the „WW ECO“ parameter,

the heat pump heats DHW exclusively on

its own, i.e. without the additional electric

booster heater. In that case, the DHW

temperature is automatically limited to that

value, which the heat pump can actually

achieve. If, for reasons of pasteurisation,

you want to heat to 60 °C at least once

every day, activate the „Pasteurisation“

parameter. In this connection, refer to your

local heating contractor.

Energy saving tip

Loading...

Loading...