39

Setting ON

DHW heating will be terminated and the set

DHW temperature is overwritten with the

actual DHW temperature, as soon as the heat

pump is shut down in DHW mode via the HP

sensor or via the hot gas temperature limit

(130 °C). This operating mode saves energy,

as the DHW is exclusively heated with the heat

pump.

DHW HYSTERESIS

This determines the switching hysteresis for

the DHW operation.

– Starting DHW heating at the DHW set

value minus the hysteresis value.

DHW CORRECTION

The DHW temperature is measured in the

lower third of the cylinder. The DHW outlet

temperature is approx. 3 K higher than the

measured temperature. This deviation is

corrected and can be calibrated, if required.

PASTEURISATION

The DHW cylinder is heated daily at 01:00 h to

60 °C, if pasteurisation has been enabled.

CNTRL DYNAMIC

Setting range 0 to 30

The selected control dynamic is a measure

of the switching gap between individual

compressors and the backup heating stages.

Normally, the selected response time

should operate sufficiently fast and without

oscillation.

Heating systems which respond quickly

require a lower value, whilst very slow

reacting systems require you to set a higher

value.

COMPRESSOR IDLE TIME

After a heat pump has been switched OFF,

an idle time is set as compressor protection.

The default idle time of 20 minutes should

generally not be reduced. Where a reduction

is required because of adjustments or repair

work, reset the idle time again to 20 minutes

after completing the necessary work.

COMP DLAY CNTR

Residual idle time

Pressing PRG enables you to scan the

compressor idle time.

SINGLE PHASE

For single phase equipment, this parameter

must always be set to ON.

QUICK START

During commissioning, you can test the heat

pump function by triggering a heat pump

quick start. When this parameter is started,

OFF appears at the bottom of the display.

Pressing PRG initiates a quick start. The

respective pumps are started after the heat

pump start. The value 60 is visibly counted

down to 0 on the display; then the display

shows ON.

After that, the heat pump and the associated

buffer primary pump are switched ON.

You terminate this function by pressing PRG

or by closing the control flap. OFF is displayed

again.

RELAY TEST

Pressing PRG and continuing to turn the rotary

selector allows you to control the WPMi relay

outputs individually. The individual outputs are

displayed as plain text.

LCD TEST

Pressing PRG once initiates a LCD test. All

display elements are displayed in sequence.

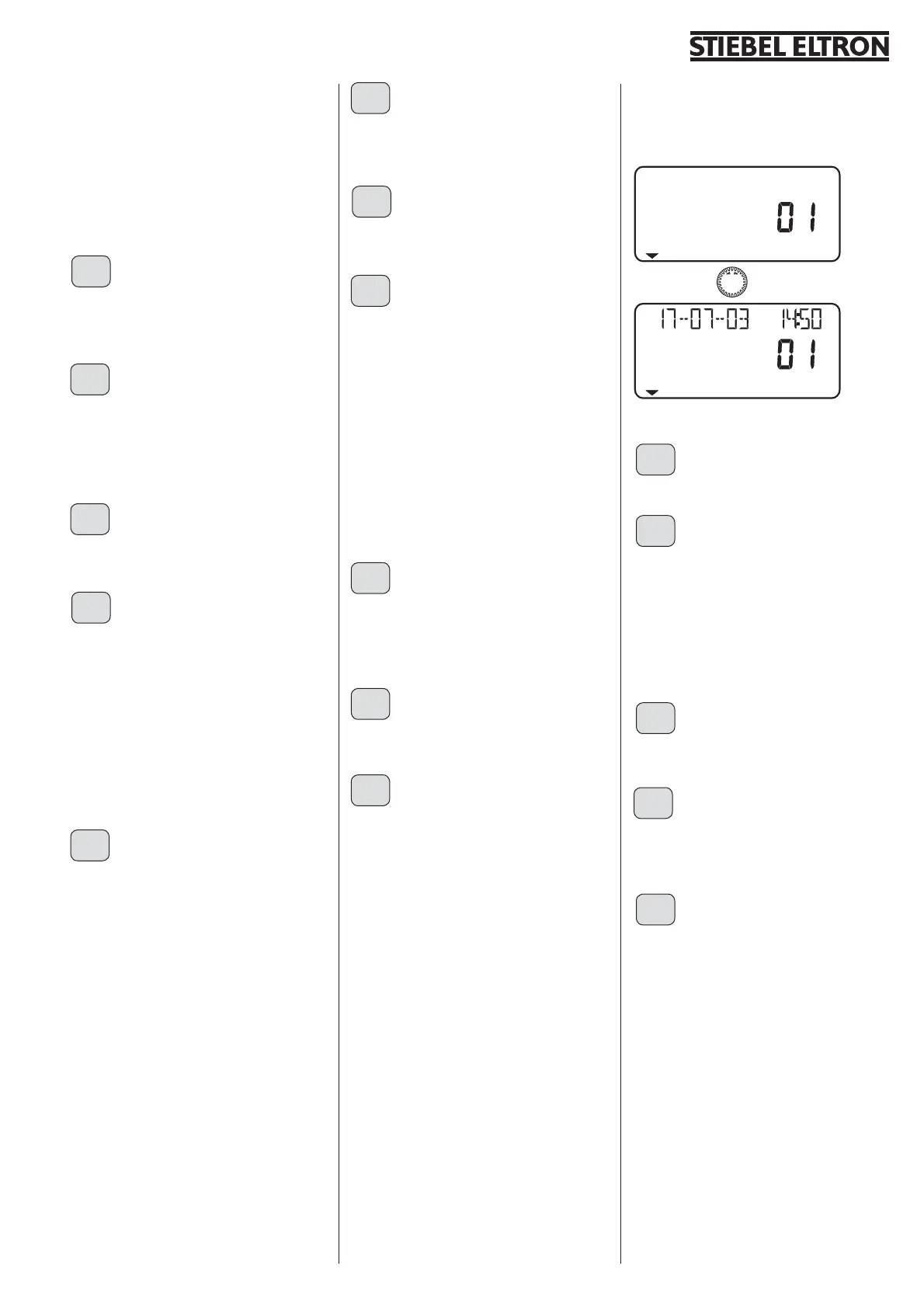

FAULT LIST

Pressing PRG displays the first fault code. The

fault is described in plain text at the top of the

display, the bottom shows the fault number.

Continuing to turn the rotary selector still

displays fault 1. As additional information,

the display shows the day, month and year

together with the relevant time, when the fault

occurred.

In total, 20 faults can be displayed. You can

reset the fault list via a hardware reset.

Example:

The high pressure switch has responded on

the 17.07.03 at 14:50 h representing the latest

fault in the heat pump.

SOFTWARE WPMiI

Display of the current software issue.

ANALYSIS

The bottom of the display shows the enabled

stages.

The two-digit display shows the internal

controller calculation. A stage will be switched

every time the counter has counted down

to zero. This calculation depends on the

controller dynamic and the control deviation.

For this, see controller dynamic.

DIAGNOSTIC (WPMi)

Pressing PRG indicates, whether an FEK is

connected.

DIAGNOSTIC (WPMiw)

Pressing PRG indicates whether an FEK is

connected and which type of heat pump is

connected.

HEAT P RESET

You can reset the heat pump in case of faults.

That fault is reset by pressing PRG and setting

the system to ON, followed by repeatedly

pressing PRG. The compressor starts again.

The fault remains in the fault list.

28

29

30

31

33

35

36

37

38

39

40

41

42

32

34

41

HP SENSOR MAX

Loading...

Loading...