22

1

2

3

4

5

6

-5 0 5 10 15 20

Quelleneintrittstemperatur [°C]

Temperaturdifferenz [K]

Sole - HV 35°C

Sole - HV 50°C

g/cm

1,130

1,120

1,110

1,100

1,090

1,080

1,070

1,060

1,050

1,040

1,030

1,020

1,010

1,000

0,990

0,980

O = Frostsicherheit

–20 –10 0 10 20 30

°C

40 50 60 70

0 VOL-% = Wasser

40 VOL-% = (-25°C)

37 VOL-% = (-23°C)

28 VOL-% = (-15°C)

20 VOL-% = (-10°C)

44 VOL-% = (-30°C)

52 VOL-% = (-40°C)

60 VOL-% = (-50°C)

100 VOL-% = Ethylenglykol

R

3

2.9.3.2 Connection and filling with brine

Prior to connecting the heat pump, check the

heat source circuit for possible leaks, and flush

thoroughly.

After filling the system with brine, and prior

to commissioning, open the fill & drain valve

(item 17, Fig. 1), until brine runs out of it. No

water must remain in the pipe run to the fill &

drain valve.

Calculate the volume of the heat source circuit.

You can obtain the brine volume inside the

heat pump from the following table.

Heat pump Brine volume

WPF 5 (S) 5,84 l

WPF 7 (S) 6,45 l

WPF 10 (S) 7,06 l

WPF 13 7,06 l

WPF 16 7,06 l

The overall volume equals that of the required

brine, which should be mixed from 33 % (vol.)

pure ethylene glycol and 67 % (vol.) water.

Mixing ratio:

1 unit pure ethylene glycol with

2 units water (max. chloride contents in the

water = 300 ppm), then fill mixture into the

system.

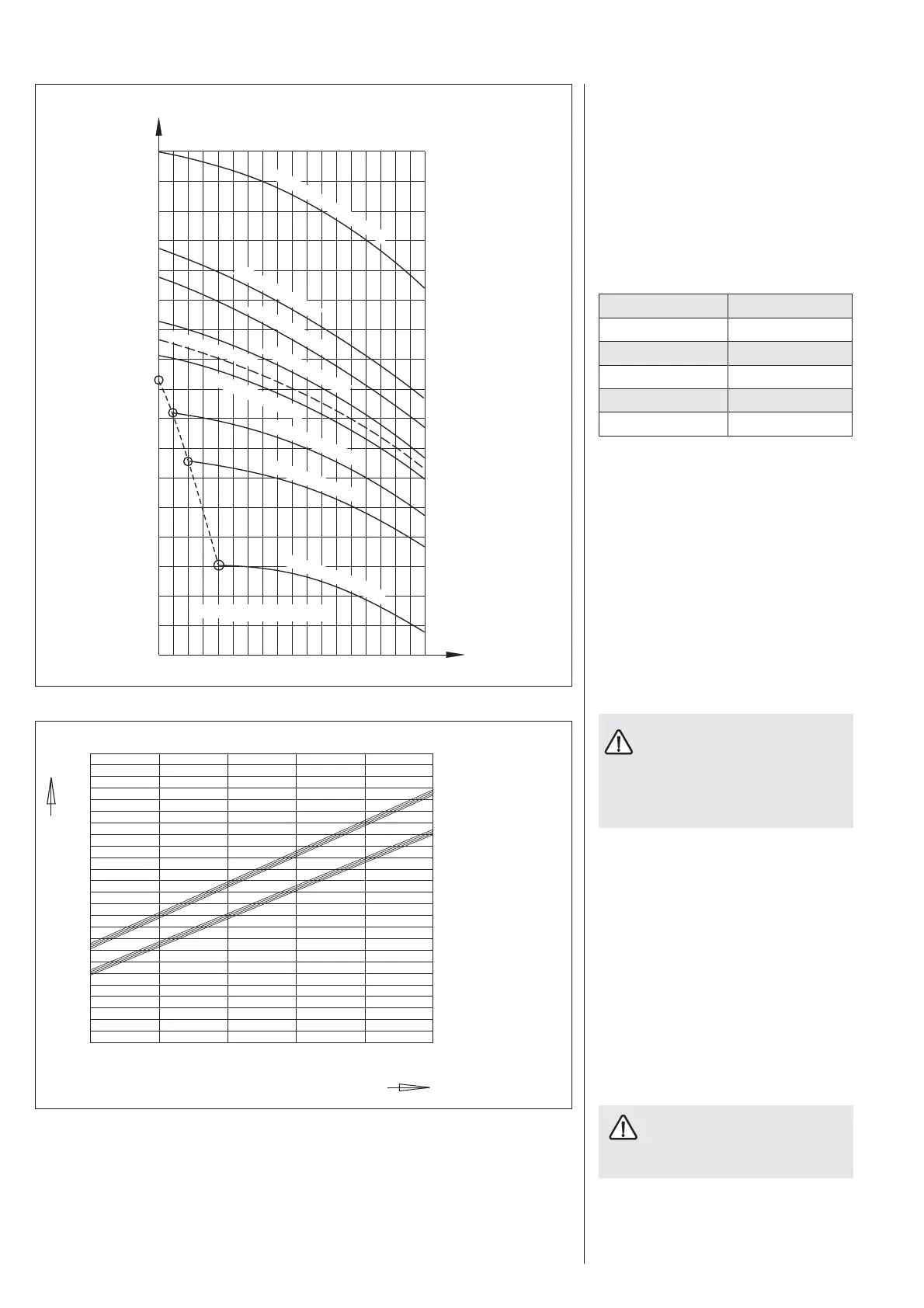

Checking the brine concentration:

Determine the density of the ethylene glycol

water mixture (e.g. with a hydrometer). Using

the actual density and temperature, you can

check the current concentration in the diagram

(Fig. 7).

The details quoted refer to ethylene

gylcol. When using propylene glycol

and the Stiebel Etron process medium as

ready-mixed solution (part no 185472),

these details will be slightly different (see

specification).

To prevent the transmission of noise, connect

the heat source circuits to the heat pump with

flexible pressure hoses

(part no. see section 2.2).

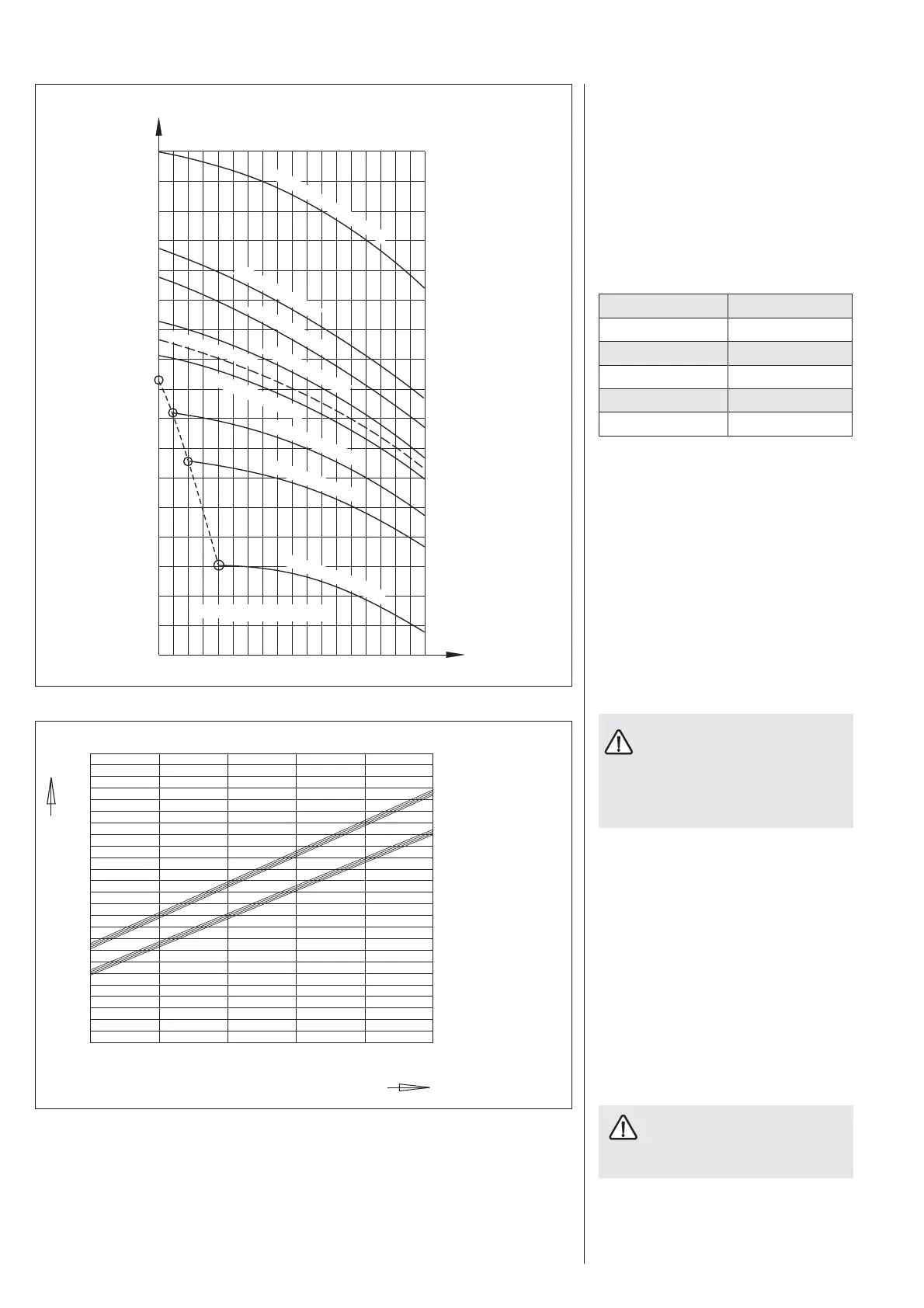

2.9.3.3 Volume flow control

(to be implemented during heat pump com-

missioning)

Measure the flow and return temperatures

of the heat source. For this, determine the

temperature difference by measuring the

temperature under the thermal insulation on

both flow and return pipes of the heat pump.

The diagram (Fig. 8) shows the temperature

spread at the rated volume flow.

You can check the source inlet tem-

perature on the WPMi display under

system parameter INFO TEMP.

Brine concentration

Temperature spread at rated volume flow

Density U of ethylene glycol-water mixtures

with different concentration levels

Brine - Flow temp. 35°C

Brine - Flow temp. 50°C

Inlet temperature of source medium [°C]

Temperature difference [K]

Water

Frostprotection

C26_03_01_0143

Fig. 8

Fig. 7

26_03_01_0092C

Loading...

Loading...