42

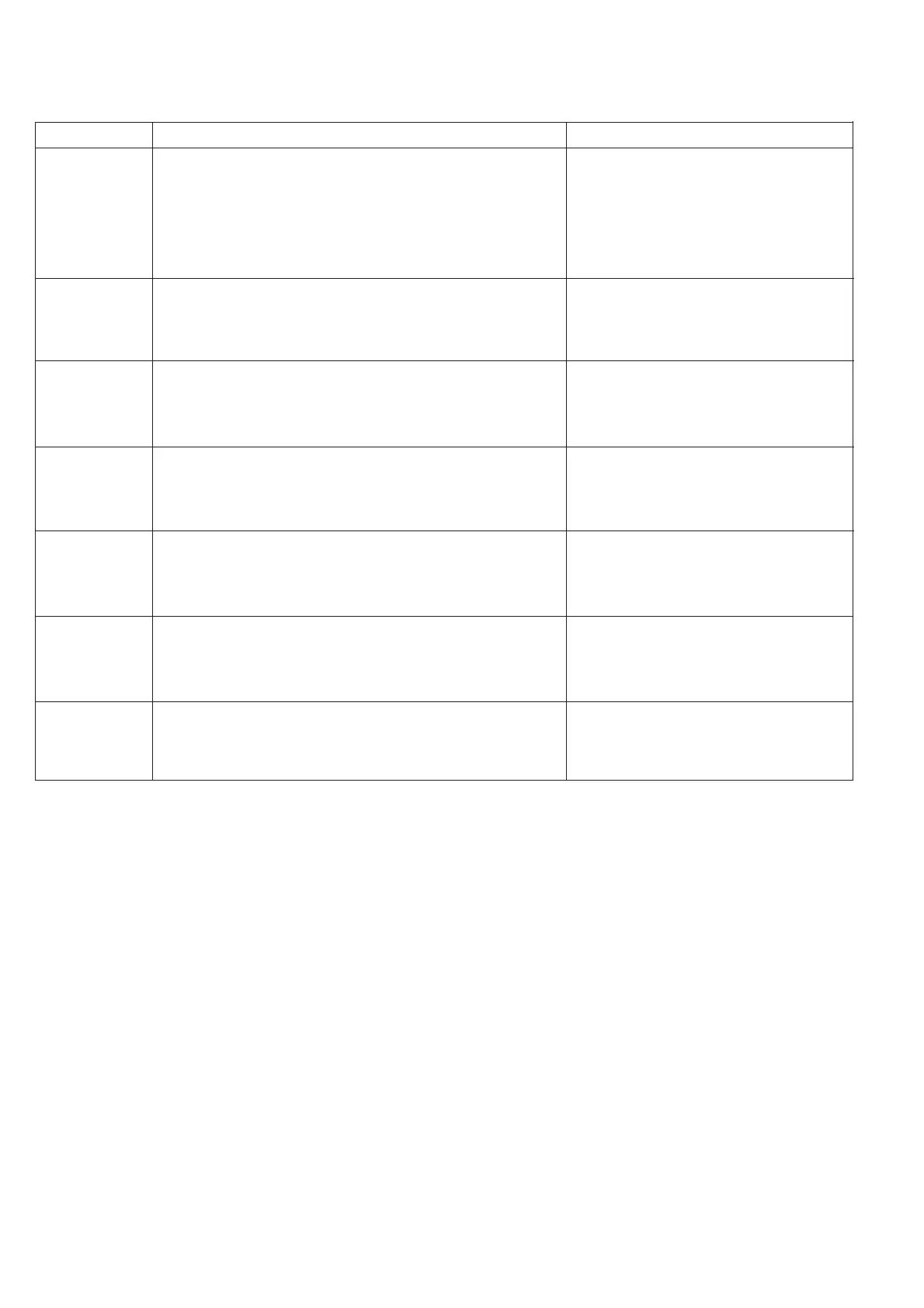

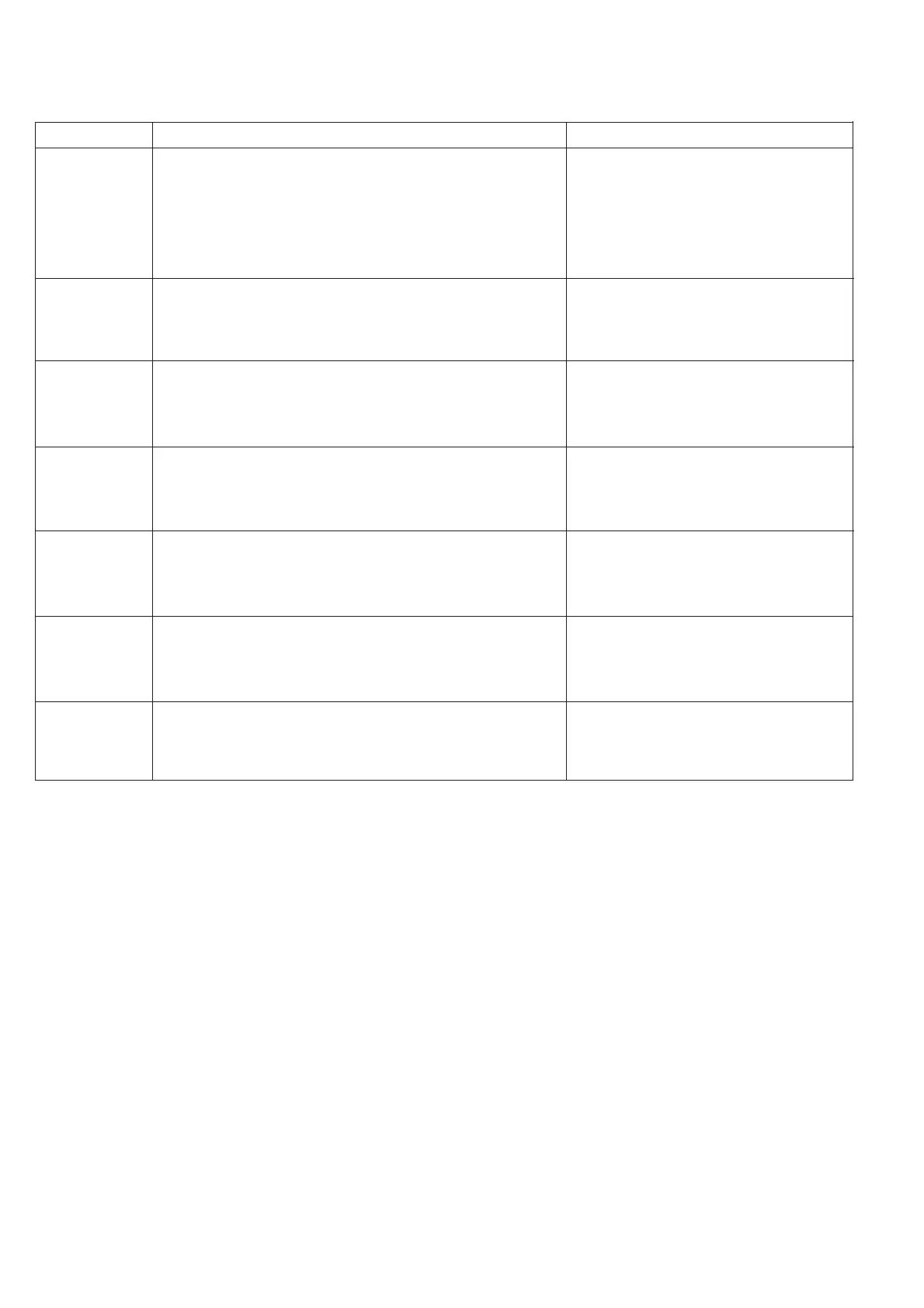

Parameter Fault list - checking and removing all faults in the fault list

Fault description:

The fault will be written to the fault list and the system will be

permanently shut down after the system has been shut down five times

within the operating time (5 minutes). Generally, the shutdown via

the HP sensor max. is a controlled shutdown that is only displayed for

information and for the duration of the idle time, i.e. it is not entered

into the fault list. Only frequent shutdowns over a short period of time

point towards a fault and are therefore entered into the fault list.

The system will be permanently shut down after the fault has occurred

five times within the operating time (idle time x 50 plus 20 minutes).

The fault will be written to the fault list after it has occurred for the first

time.

Each time the compressor is switched OFF, the system checks after 10

seconds, whether the relay K9 is open. A contactor is stuck, if that is the

case. The fault is written to the fault list, and the system is permanently

shut down.

After the compressor has started, and after a delay of 15 seconds,

masking checks, whether the relay K9 is open. An HP limit switch has

responded, if that is the case. The fault is written to the fault list, and the

system is permanently shut down.

After the compressor has started, the pressure must have risen by 2 bar

within 10 seconds. A fault has occurred, if that is not the case, and the

fault will be written into the fault list, if that is its first occurrence. The

system is then permanently shut down.

The defined minimum source temperature was not reached. The fault is

written to the fault list.

The compressor starts again after the selected idle time has expired.

The compressor will be stopped for the minimum idle time if a hot gas

temperature of 130 °C is exceeded. This is a normal controlled shutdown

that is not entered into the fault list. The reason for the shutdown is

displayed for information during the idle time.

Remedy

Only when a fault has been entered into the fault

list: Check the flow temperature monitoring and

the HP sensor.

Check the volume flow and temperature on the

heating side.

Check the volume flow and the layout of the

source side.

Check the refrigerant level (sight glass).

Check contactors K1 and K2 and replace, if

required.

Monitor the flow temperature and check the high

pressure sensor.

Check the volume flow and the temperature on the

heating side.

Compressor turns in the wrong direction.

Change the rotational direction by interchanging

two supply cores

Check the minimum source temperature and

change it, if required.

Check the source volume flow. Check the source

layout.

This requires no action, as it is a controlled

shutdown

Fault

High pressure

sensor max

Controlled

shutdown.No fault.

Low pressure

Contactor stuck

High pressure

No power

Source min.

Hot gas max.

Controlled

shutdown.No fault.

Loading...

Loading...