www.stiebel-eltron.com WPM 3| 47

INSTALLATION

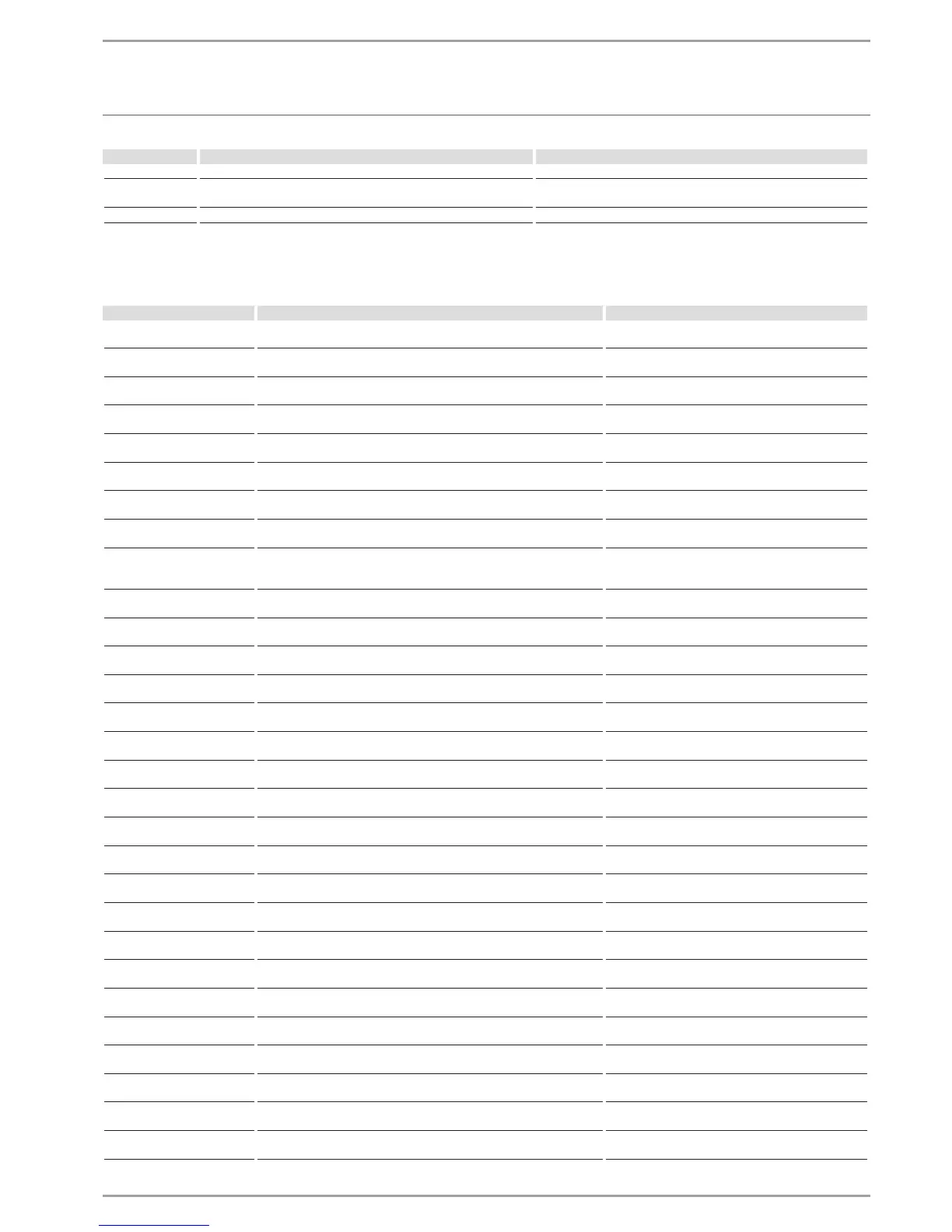

Troubleshooting

Fault display Reason for fault code being triggered Possible cause of fault / remedy

CONTACTOR STUCK Compressor or starting contactor sticks Check contactors K1 and K2

MIN SOURCE The defined minimum source temperature was not reached. Check the minimum source temperature and change it if required.

Check source flow rate: Check source sizing.

NO IWS PARAM Heat pump type was not transferred to the controller Select heat pump via heat pump type parameter

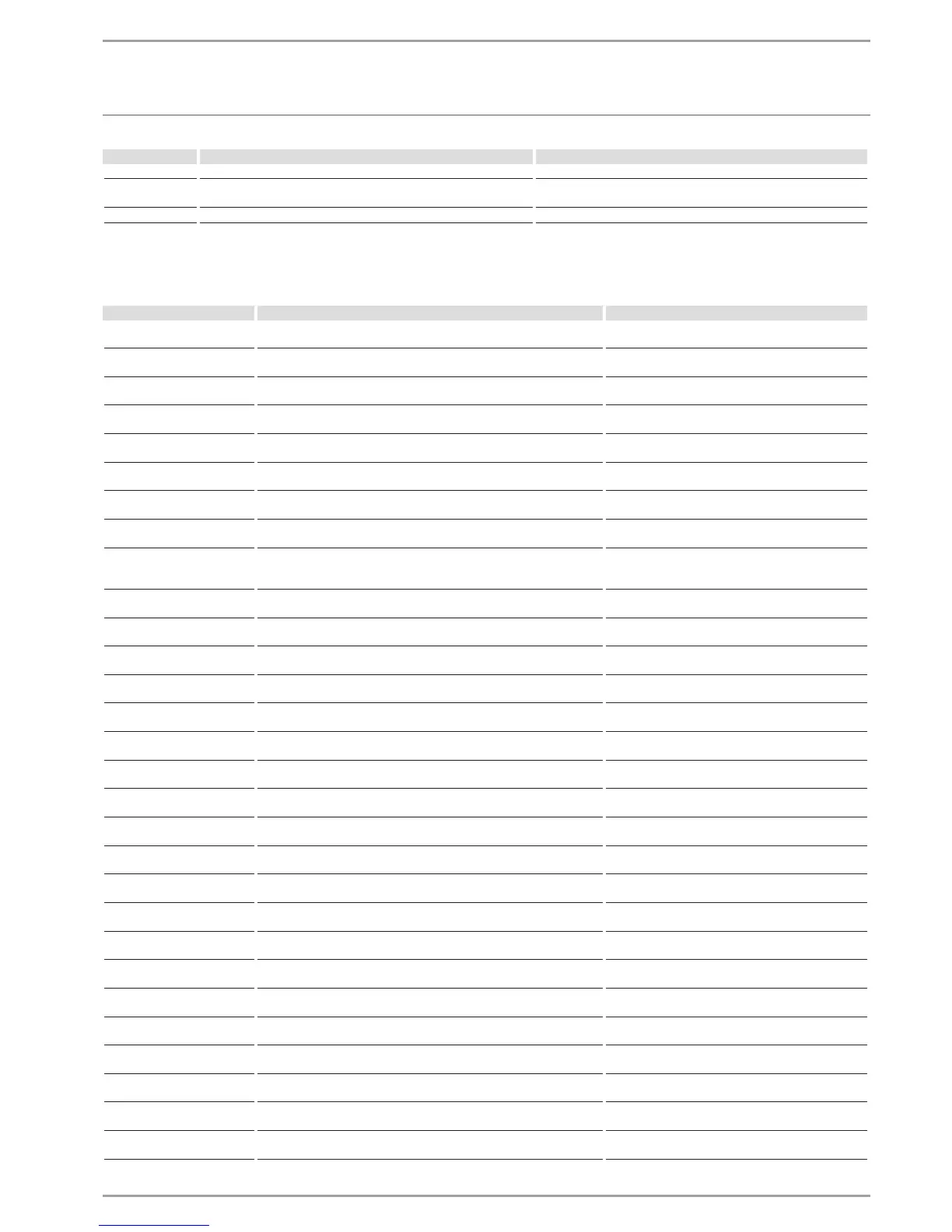

Fault list for HP TYPE 3 and 3*

Fault display Reason for fault code being triggered Possible cause of fault / remedy

LOW PRESSURE The minimum low pressure limiter has been triggered (below 2 bar for

10 s)

Refrigerant escaped. Expansion valve does not open.

ERR ND PRESSURE Multiple response from the LOW PRESSURE limiter in a defined compres-

sor runtime

Remove the cause. Then carry out a WPM reset.

MEAN PRESSURE The minimum mean pressure limiter has been triggered (below 2 bar for

10 s)

Refrigerant leak, expansion valve does not open

ERR MD PRESSURE Multiple response from the MEAN PRESSURE limiter in a defined com-

pressor runtime

Remove the cause. Then carry out a WPM reset.

HIGH PRESSURE The high pressure limiter has responded (switching point 42bar) Check the flow rate and sensor connection on the heat-

ing side.

ERR HD PRESSURE Multiple response from the HIGH PRESSURE limiter in a defined compres-

sor runtime

Remove the cause. Then carry out a WPM reset.

NO OUTPUT High pressure does not increase significantly above low pressure follow-

ing compressor start-up and a delay time

Heat pump connection fuse has blown. Remove the

cause. Then carry out a WPM reset.

ERR K OUTPUT Multiple response from the NO OUTPUT limiter in a defined compressor

runtime (high pressure < low pressure + 2 bar within 120 s)

Remove the cause. Then carry out a WPM reset.

MIN SUPERHEATING

Superheating of the refrigerant at the evaporator outlet or the compres-

sor inlet for too long below the permissible limit (superheating is < mini-

mum superheating value for 10 minutes)

Expansion valve not working correctly.

ERR M SUPERHEATING IWS Multiple response from the MIN SUPERHEATING limiter in a defined com-

pressor runtime

Remove the cause. Then carry out a WPM reset.

REFRIGERANT LOW Unexpectedly high deviation of the expansion valve opening from the

pre-control characteristic

Refrigerant leak. Expansion valve does not function

correctly.

ERR K LOW IWS Multiple response from the REFRIGERANT LOW limiter in a defined com-

pressor runtime

Remove the cause. Then carry out a WPM reset.

SPEED DEV COMP ND Speed deviation between set and actual compressor values for a defined

time

Inverter or compressor not working correctly.

DEFROST Flow temperature or frost protection temperature < 10 °C, or flow rate <

10 l/min (WPL 15), < 15 l/min (WPL 25) in defrost mode is too low

Water flow rate too low. Water temperature too low.

ERR DEFROST Multiple response from the DEFROST limiter in a defined compressor

runtime

Remove the cause. Then carry out a WPM reset.

HEXADECIMAL SWITCH The heat pump type DIP switch of the IWS is set incorrectly. Isolate the heat pump from the power supply and set

the DIP switch correctly.

HD SENSOR MAX The maximum high pressure limiter has been triggered (42 bar) Heating system flow rate too low. Selected room tem-

perature / heating curve too high.

MAX HOT GAS Hot gas temperature has exceeded limit (140°C) Injection valve not working correctly. Expansion valve

not working correctly, refrigerant leakage.

ERR T VOR IWS Sensor value of the flow sensor outside the permissible range Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T RUE IWS Sensor value of the return sensor outside the permissible range Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T FROS IWS Sensor value of the frost protection sensor outside the permissible range Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T VFL IWS Sensor value of the condenser outlet sensor outside the permissible

range

Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

NO IWS PARAM Heat pump type was not transferred to the controller Select the heat pump type via the HEAT PUMP TYPE

parameter.

ERR T AUS IWS Sensor value of the outside temperature sensor outside the permissible

range

Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T EXHA IWS Sensor value of the exhaust air sensor outside the permissible range Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T EIN IWS Sensor value of the injection temperature sensor outside the permissible

range

Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T SUCT Sensor value of the compressor inlet sensor (suction gas temperature

compressor) is outside the permissible range

Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T VER IWS Sensor value of the evaporator temperature sensor outside the permissi-

ble range

Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T HTG IWS Sensor value of the hot gas temperature sensor outside the permissible

range

Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

Loading...

Loading...